Compressing a Compression Spring

Compression springs are quite useful in many devices, applications and situations. Their ability to compress and then extend to their original length when the compressing force is removed, makes them ideal for different applications. You can find compression springs being used in buttons, pens, and all kinds of devices where automation is required.

The push-back effect that springs are able to create is thanks to the energy the spring stores when a force is applied. When force is applied to the spring, it compresses. As it is compressed, it absorbs energy. When that force or load is removed it releases that energy allowing it to push back the coils into its original shape, thus releasing the energy it stored. There are two cases where a spring will not return to its original length.

One, is when you place an exceeding load or force on the spring and it pushes the spring down so far that it ends up “taking a set”. This causes the spring to lose its ability to return to its original shape.

The second case is when the spring is intentionally placed in a “pre-loaded” position. In a pre-loaded position, a spring is placed into a space within a device where it is restrained and kept from being at its full free length. This is done to to either gain more force during deflection or keep the spring in place. It is important to note that the spring should be able to return to its original free length if removed from the application or enclosed space that is maintaining its pre-loaded position.

The ability to exert a force that is both equal and opposite to the external force is what makes compression springs so helpful for different applications. A perfect example of how the energy in compression springs works are pogo-sticks.

Pogo-sticks have a big compression spring that allow it to complete the function of impulsing a high jump. When you get on a pogo-stick, the more force you apply to it, the more force it exerts back and the higher you are able to jump as it springs back. The same occurs in other compression spring applications.

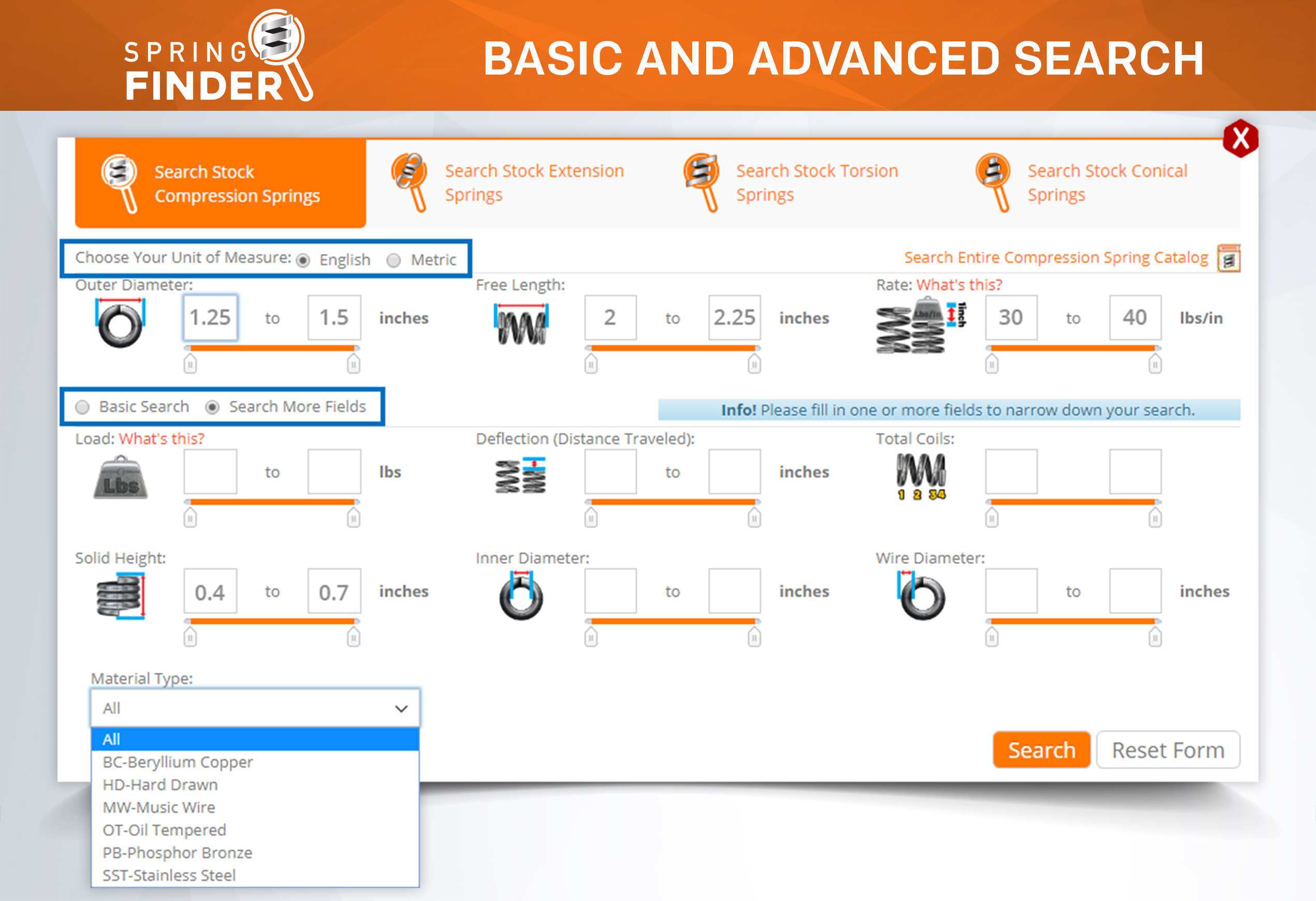

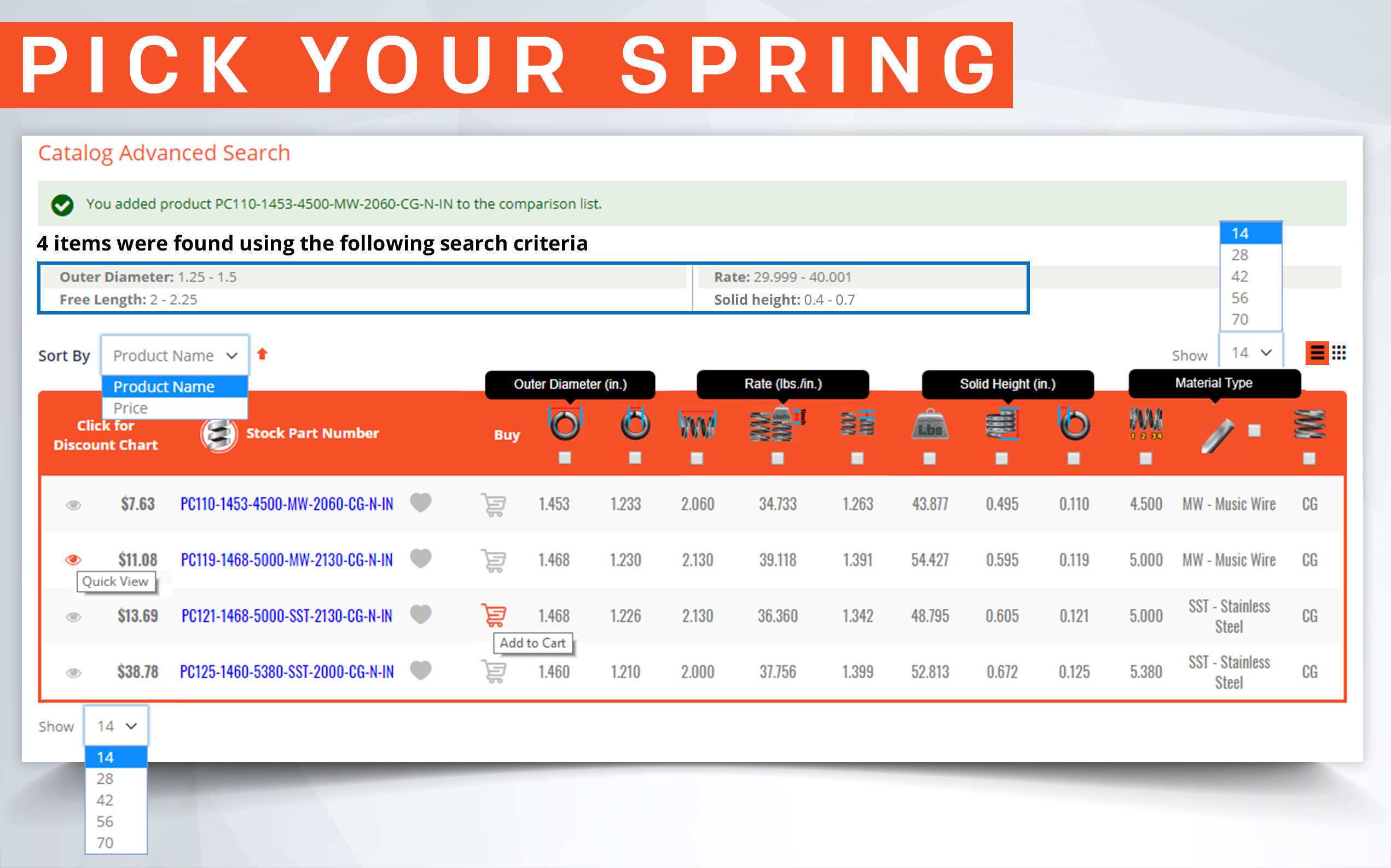

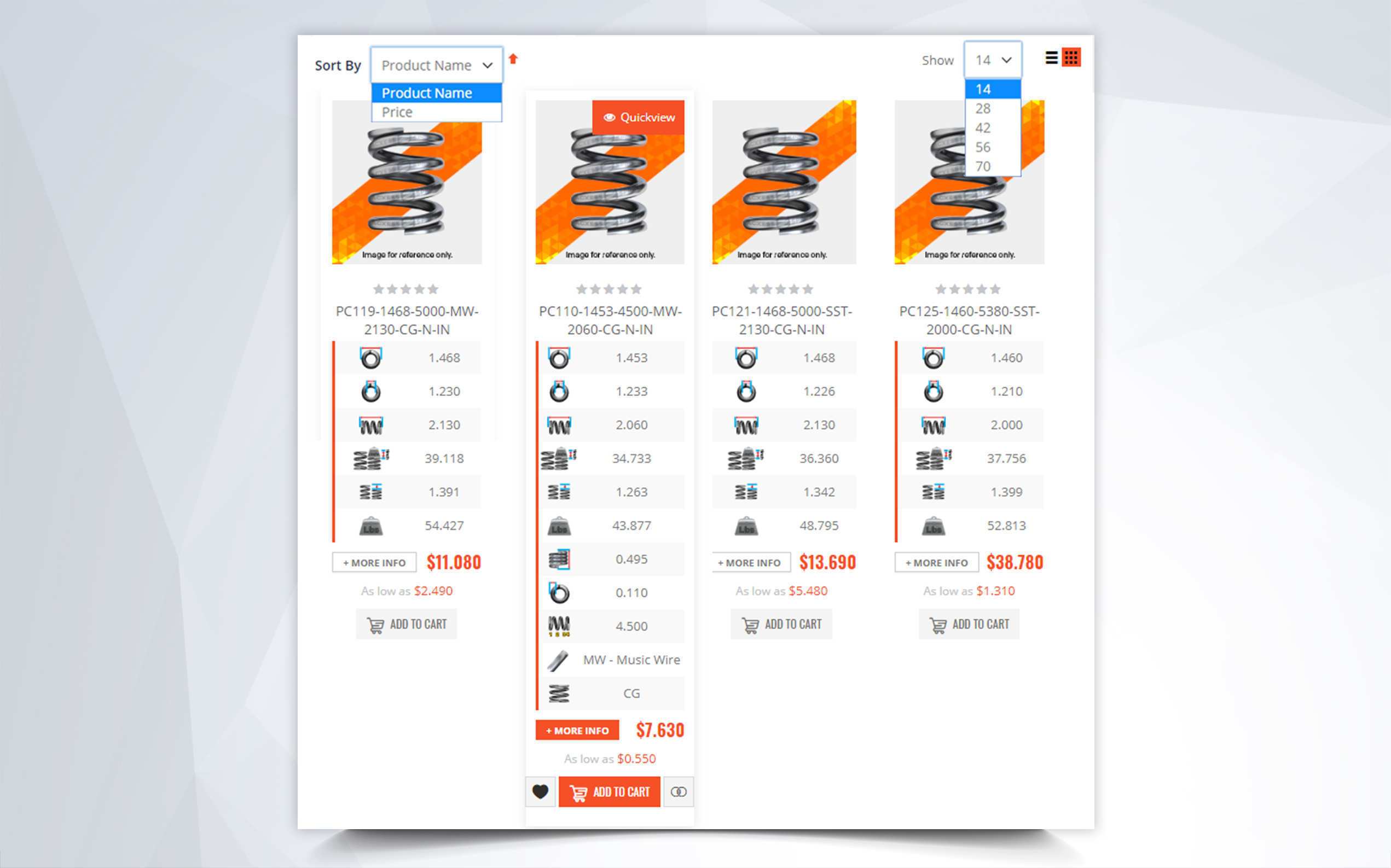

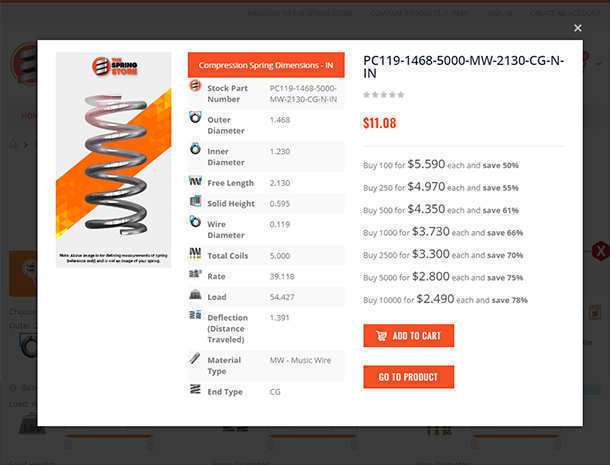

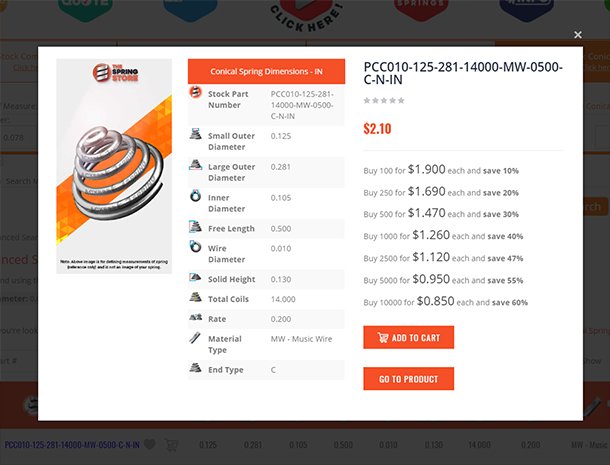

As you can see, compression springs pack a lot of “bounce” into even the smallest coiled metals. It is important that you know how big you need your spring to be or what space you have to fit it into. This allows you to workout the other dimensions and necessary aspects so you can select one that can also withstand the force you need it to.