Compression Spring Applications

Compression springs are everywhere!

You may have been using many devices or products that contain compression springs without even knowing it.

At CompressionSpring.com, we offer a huge selection of compression springs to fit each one of the many applications they are used for. Some of these compression springs are found in common, everyday items or devices, while others are required for more specialized applications.

Compression springs can serve many functions but they all work the same. They are pushed (compressed) by a force, and then extend to their original length once the pushing force is removed. This motion can be manipulated to create a certain outcome or function based on their spring rate. The spring rate determines a spring’s force (stiffness). You can use spring rate to determine how much your spring will compress under a specific load.

For example: some compression springs can be pre-loaded within an application and then released when needed. One application that perfectly fits this description are auto-injector syringes.

Auto-injector syringes are spring-operated syringes that work similarly to click-pens. The needle is kept retracted, and then, at the click of a button, it is pushed out by a preloaded spring. To learn more about this application and how springs assist it, click here: Compression Springs for Auto-Injector Syringes.

Buttons are a common compression spring application. There are different types of buttons and each can have a different mechanism. Push-spring buttons have a mechanism that allows the button to be held down to turn a device on, and keep it on while it is held. Once they are released, they push the button back out to turn the device off.

Compression springs can also be found in many other applications; from your everyday click-pen, to the lotion pump in your bathroom. They come in all sizes and lengths, and can be created for specific devices in the medical industry, amongst others.

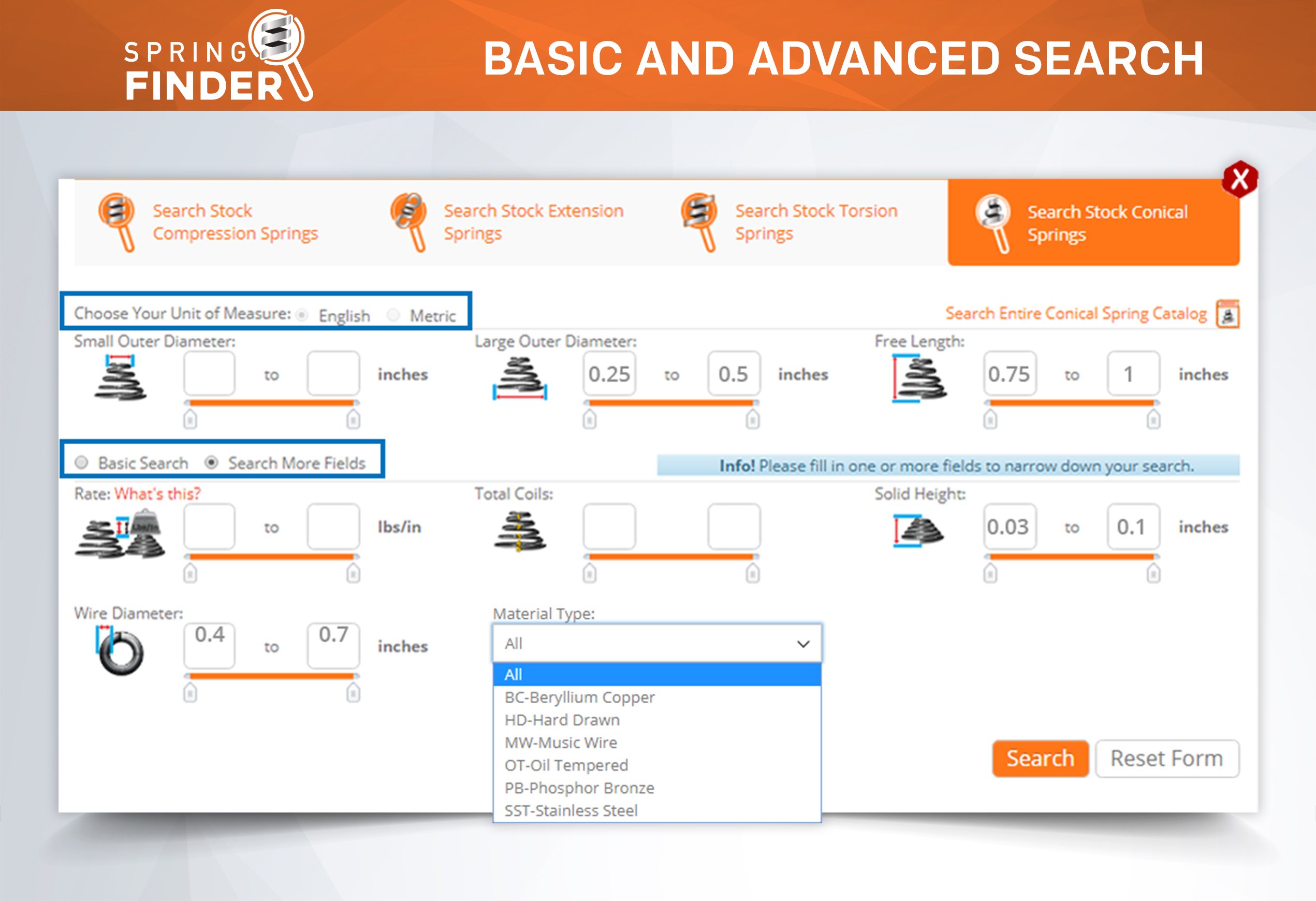

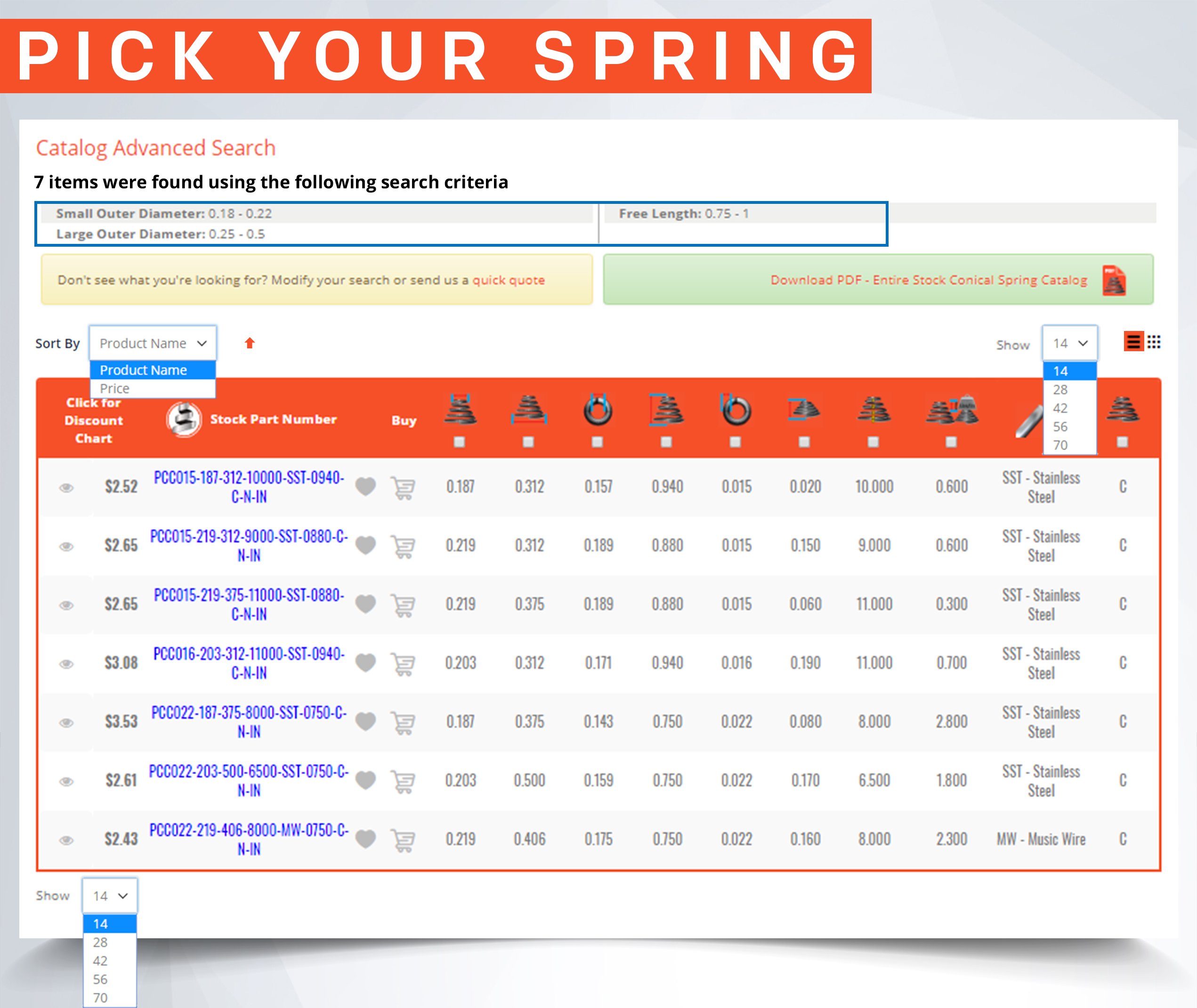

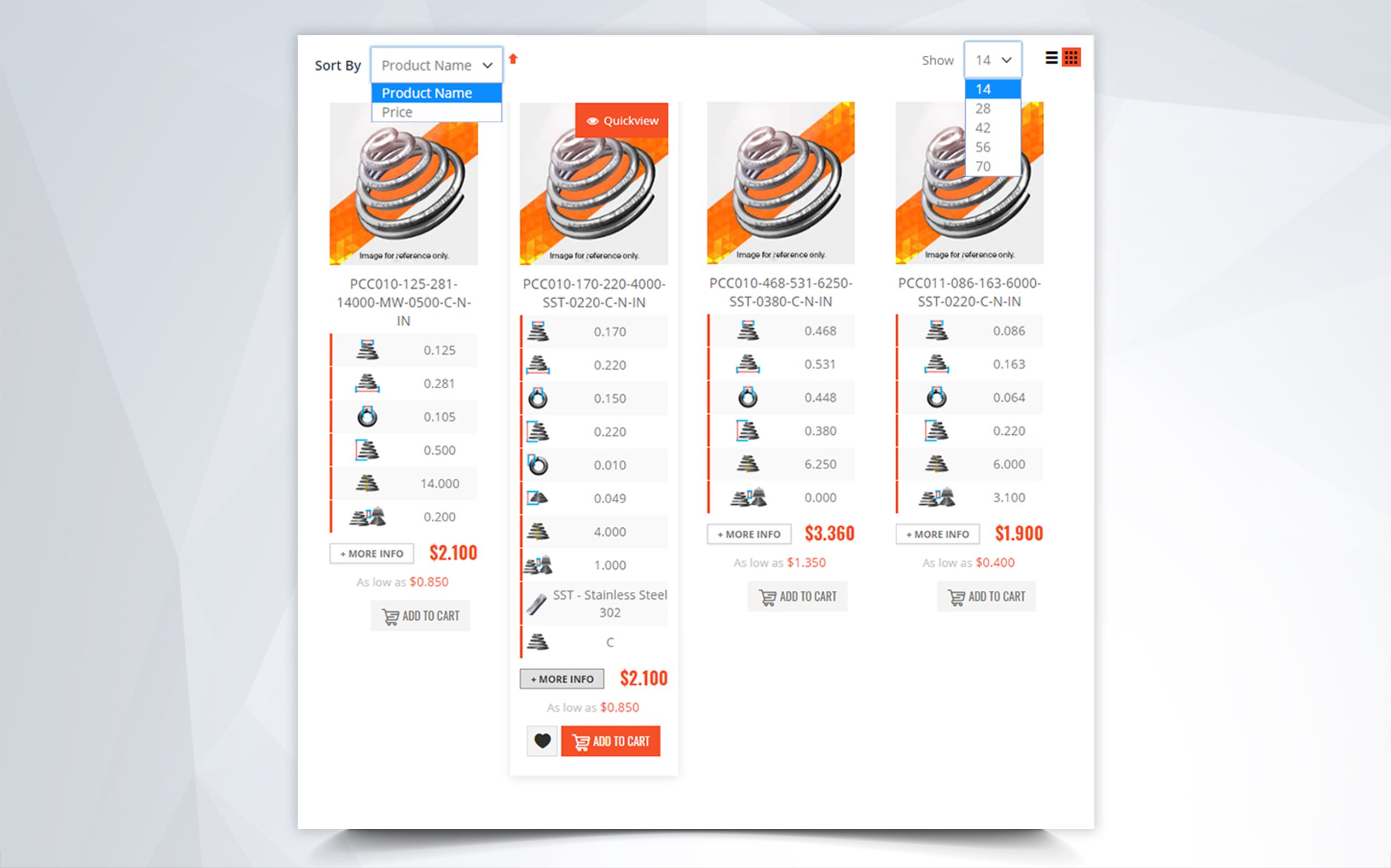

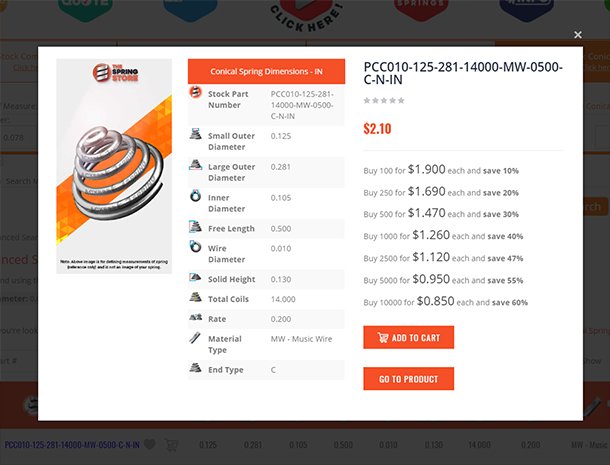

Conical springs are a type of compression spring that has a tapered shape. These are ideal for confined spaces where the function of a compression spring is required but you need a lower solid height. Conical springs can usually compress further, and even perform a telescope effect to reduce the space of solid height. Not to mention that the wire type you use can also be quite helpful for different applications. Such is the case of battery compartments in a remote control or kid’s electrical toys. Many of these conical springs are made of beryllium copper because of their conductive properties.

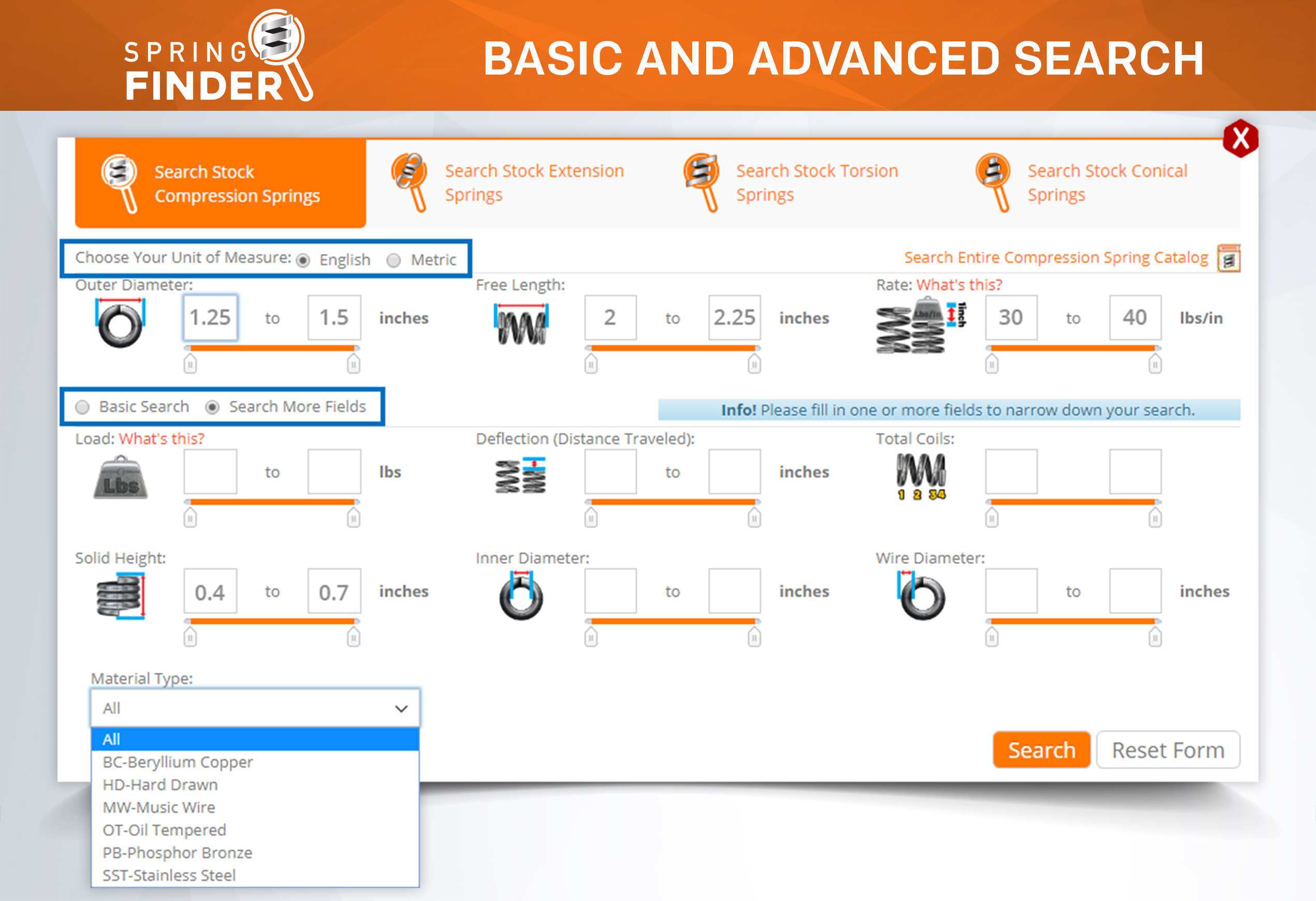

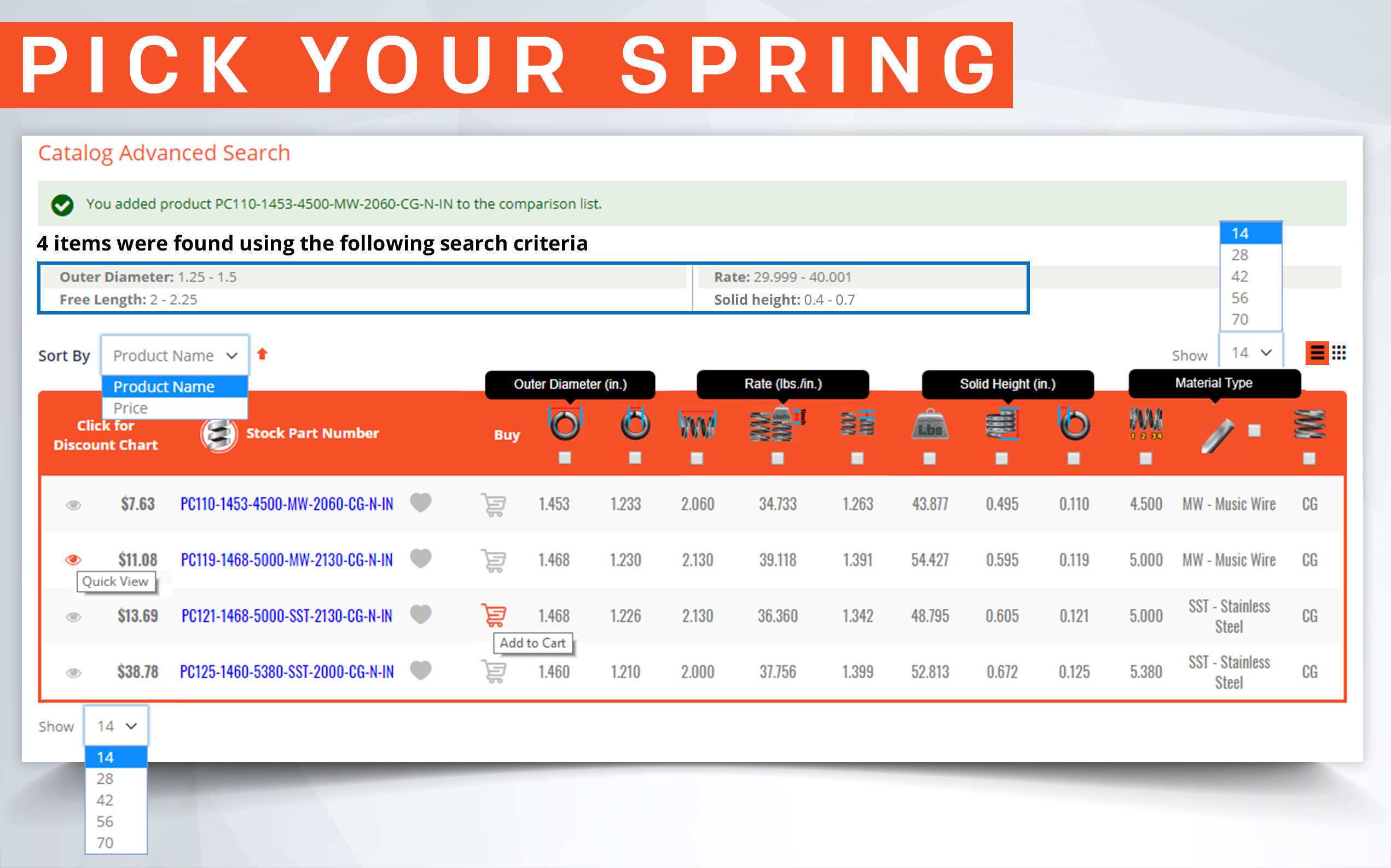

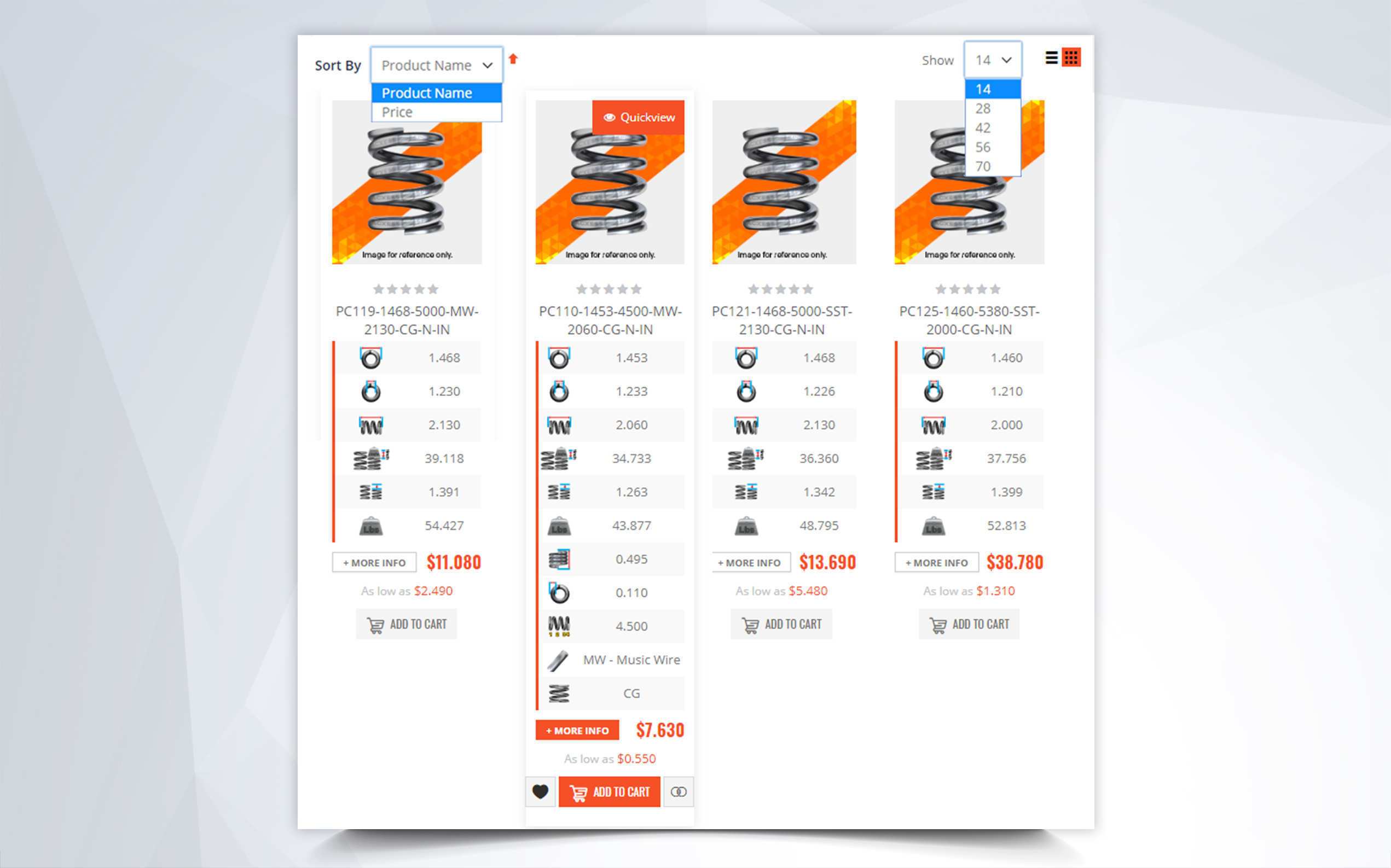

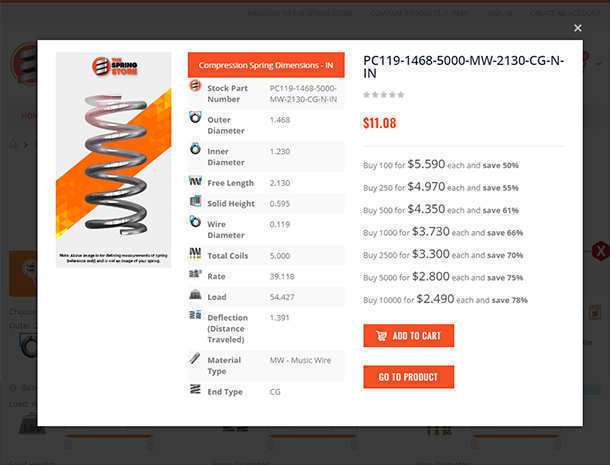

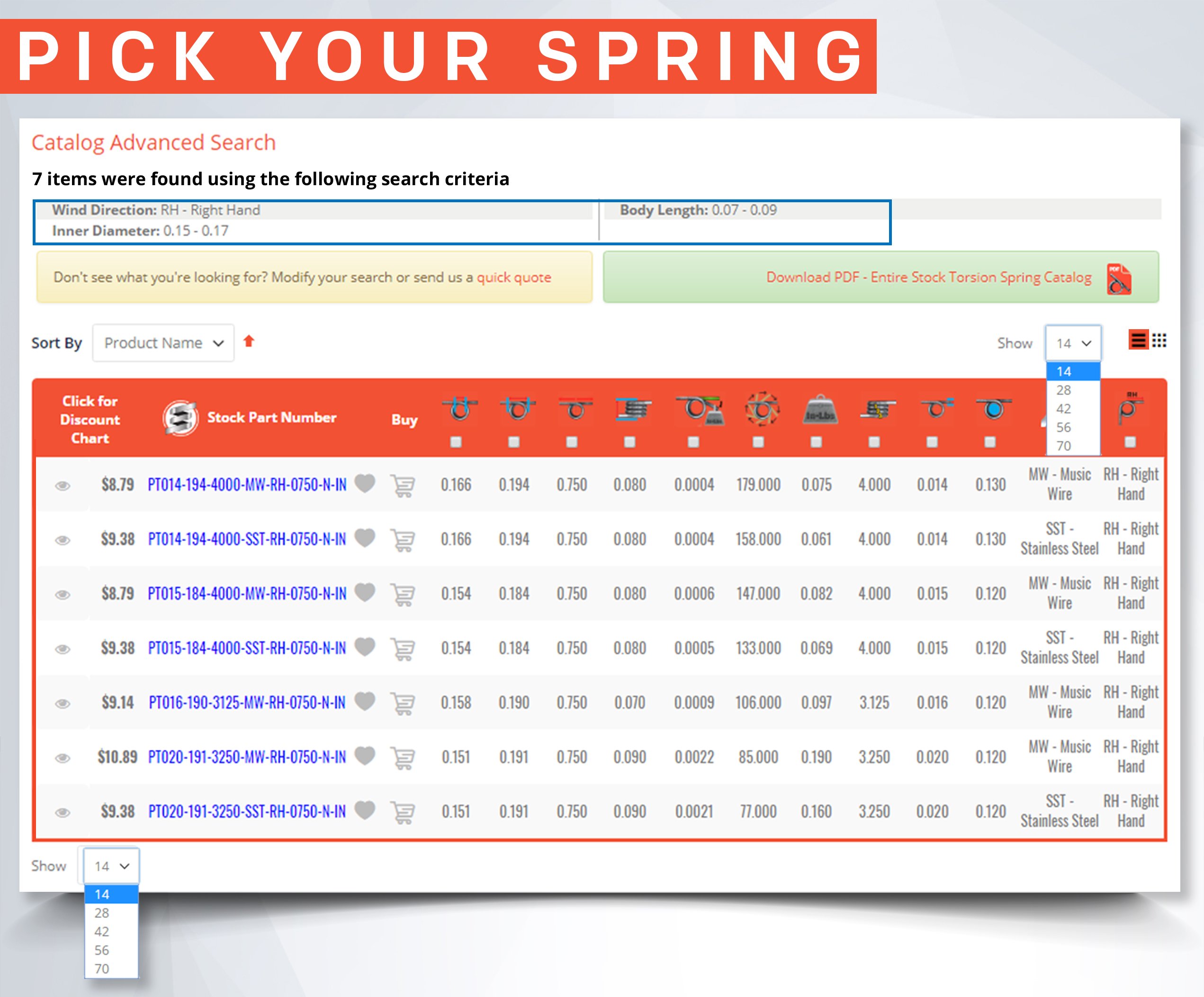

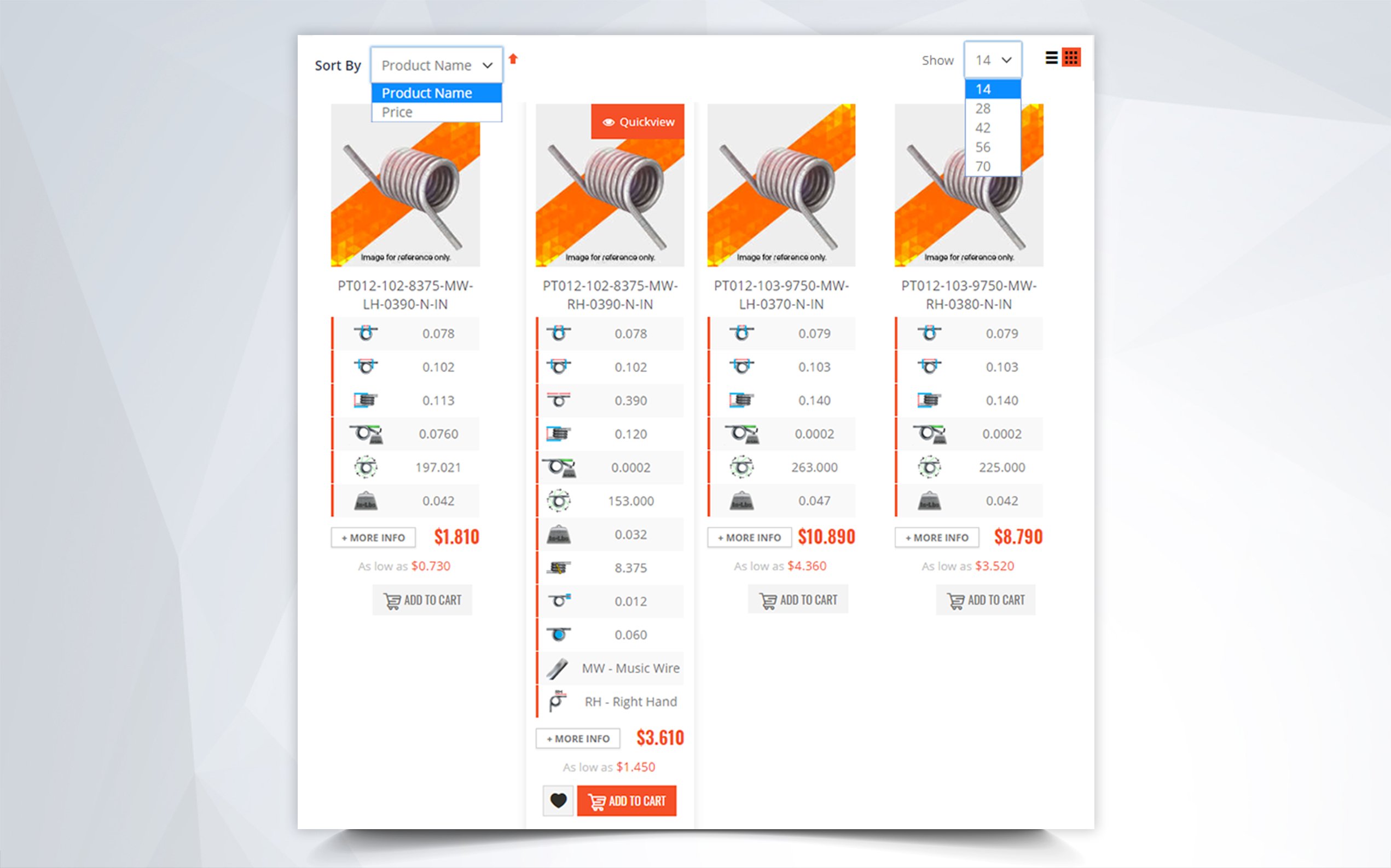

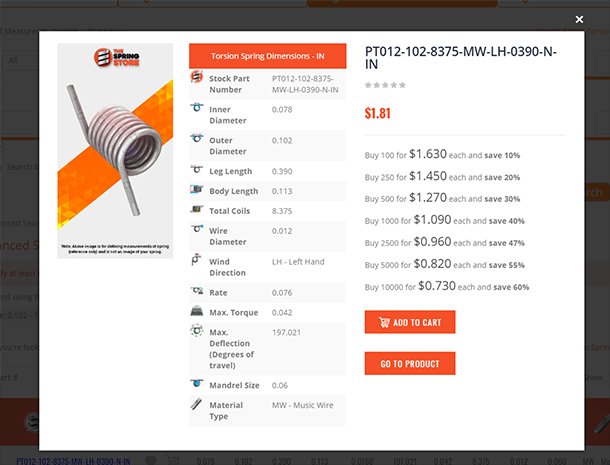

Because we have thousands of compression and conical springs, and they are used in millions of products, it is important that you know the dimensions of the spring you require. We don't keep track of what each spring we sell is used for, so we have no way of knowing what spring you need if you mention a certain product or model.