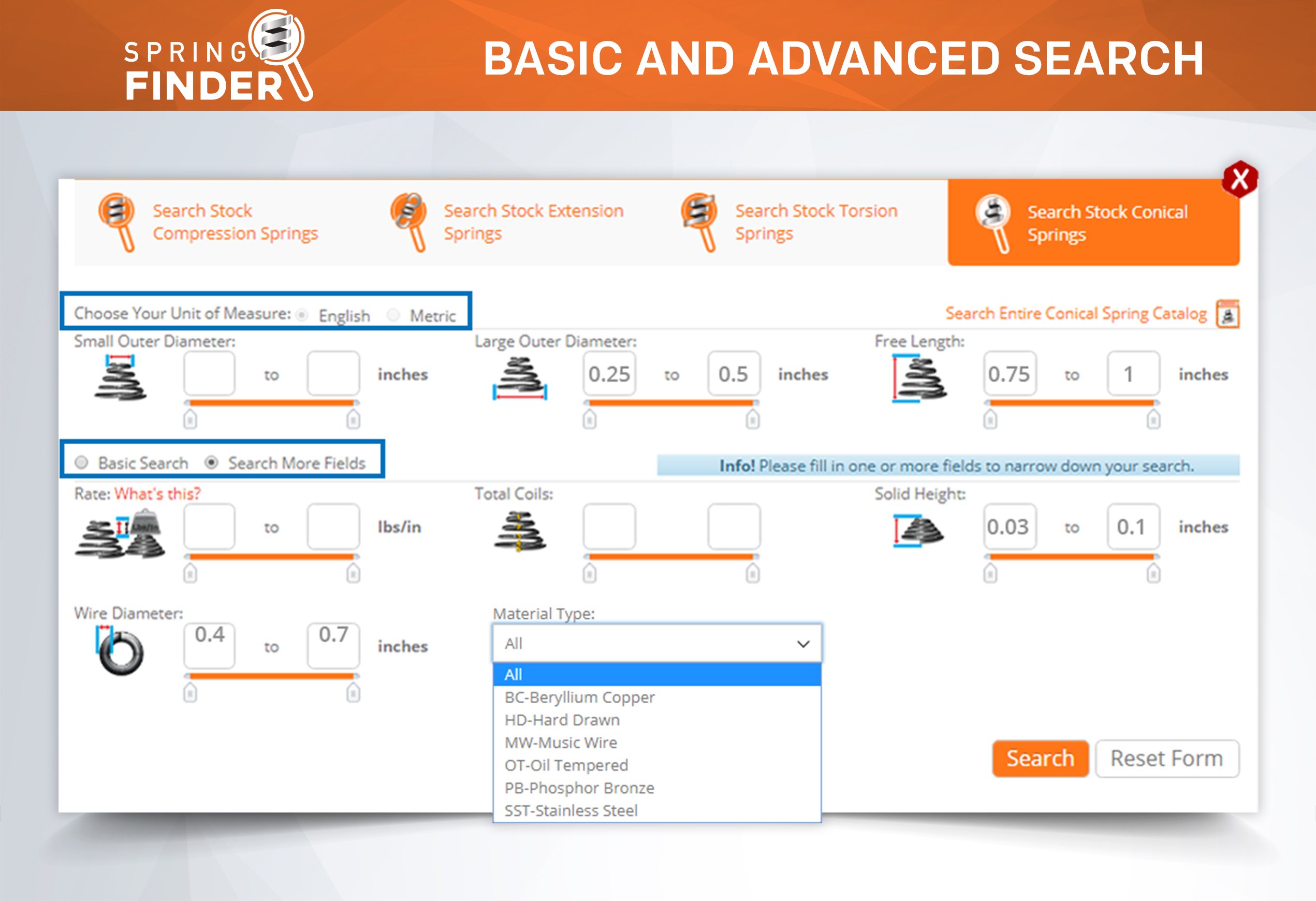

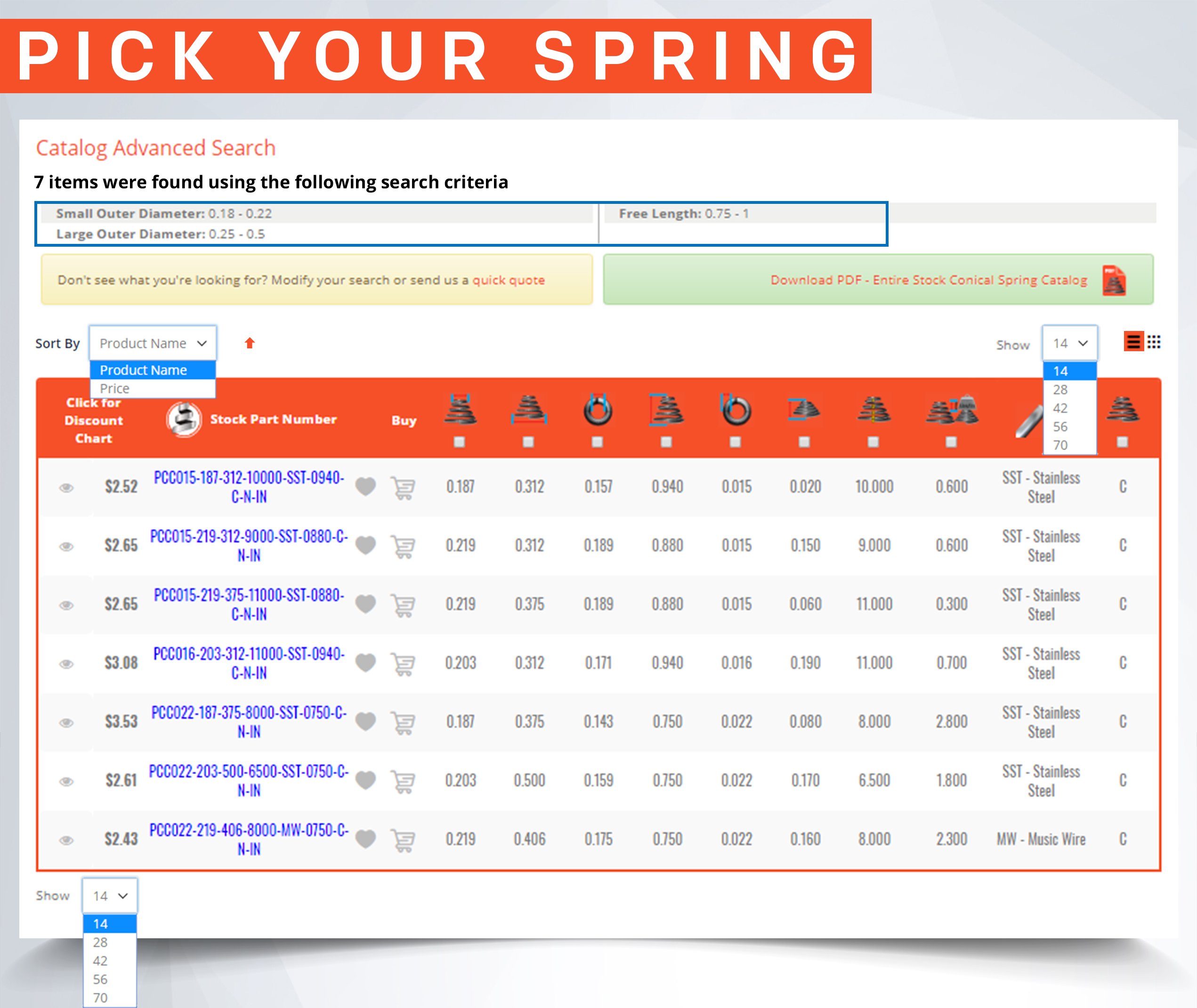

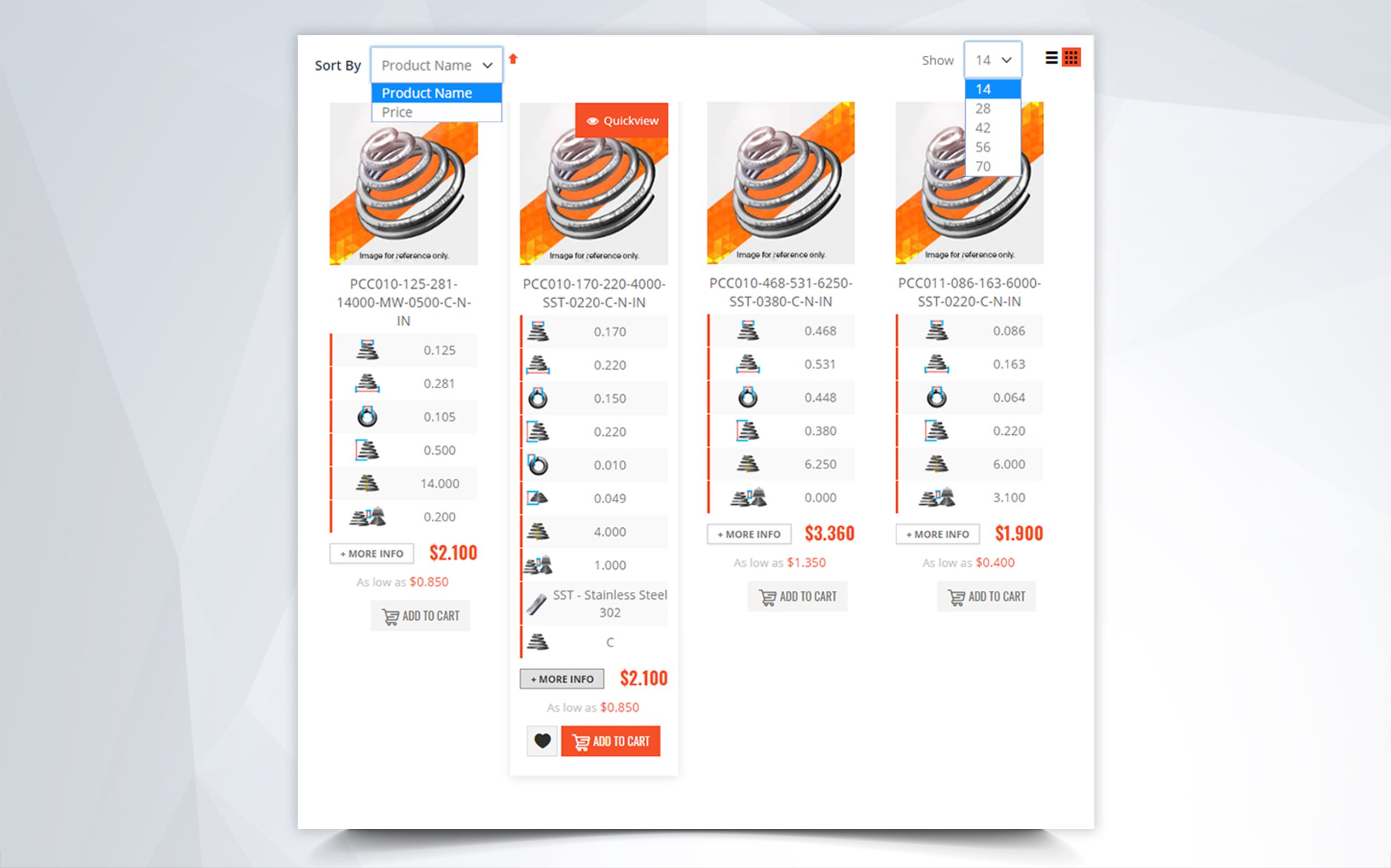

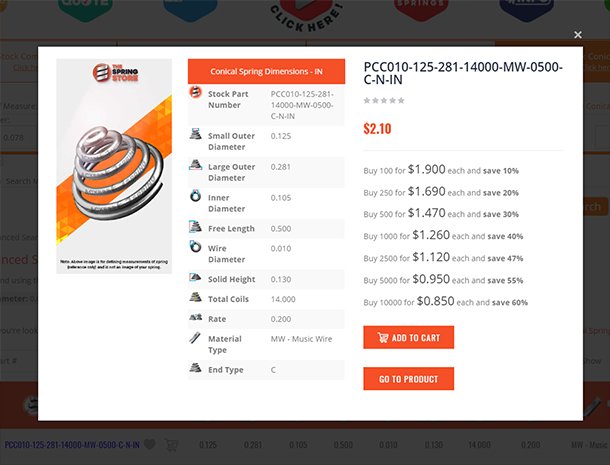

Understanding Tapered Spring Dimensions

Conical or tapered springs are compression springs coiled in increasing or decreasing outer diameters. This causes it to have a shape or form similar to that of a cone or tapered one. These springs tend to reduce solid height (the length of the spring when compressed) and provide stability.

Tapered Springs

The shape of these tapered springs also means that there are certain dimensions and measurements that will be significantly different from those of a normal compression spring. That is why we have provided the following list and descriptions of a tapered spring's dimension.

Tapered

The diagonal shape of a conical spring’s sides.

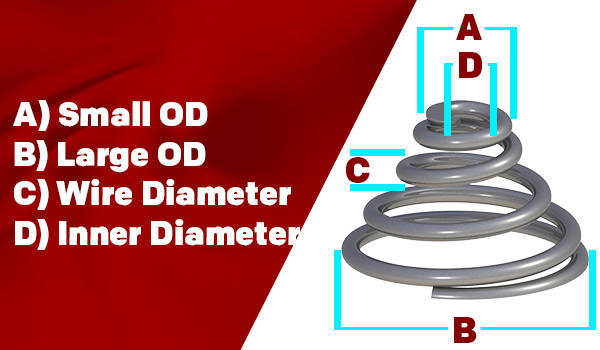

Wire Diameter (WD)

- The thickness of the round wire which the compression spring is made of.

- The thickness of the larger coil at one end of the compression spring’s body.

- The thickness of the smaller coil at the other end of the compression spring’s body.

- The width of the inside of the smallest coil. Calculate by subtracting two wire diameters from the small outer diameter.

- The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculated by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Large Outer Diameter

Small Outer Diameter

Inner Diameter (ID)

Mean Diameter (MD)

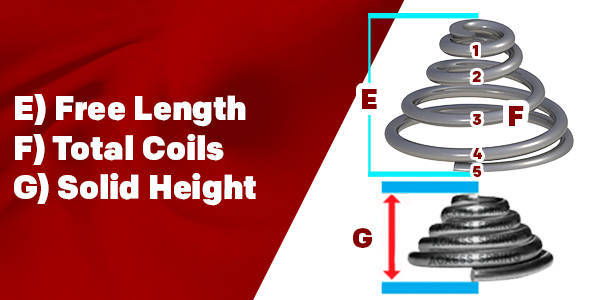

Free Length (FL)

- The free, unloaded length of a tapered spring.

- The total amount of coils including open and closed coils.

- The open/active coils in your cone spring. You may calculate the active coils by subtracting the closed coils from the total coils.

- The length/height of your conical spring when it is fully compressed and all of the coils are touching or have fully telescoped.

- The distance between your spring’s coils.

Total Coils (T/C)

Active Coils (A/C)

Solid Height (LH)

Pitch (P)

Rise Angle of Coils

- The free, unloaded length of a tapered spring.

- The proportional ratio between your spring’s wire diameter and mean diameter (measured from both the small and large outer diameters). It specifies the tightness of your compression spring’s coils and the level of manufacturing difficulty.

- The motion in which a conical spring is compressed. The distance traveled is the difference between the free length and the loaded height.

- The force being applied on the spring in order for it to travel.

Index (I)

Travel (F)

Load (P)

As you can see some of these dimensions are similar to those of a compression spring while others need to be taken into consideration in a different manner than you would a regular compression spring due to the shape that the tapered spring embodies. If you have any questions or doubts when it comes to measuring or selecting the perfect conical spring to purchase, you can contact us at: (951) 276-2777