Compression Spring Dimension Measurements

Definition

A compression spring dimension is the measurement of the elements that make up your compression spring.

To buy compression springs online, any type of compression spring, you must know your spring’s dimensions. Knowing the working loads or the spring rate will not be enough because that can make the spring any size in diameter or length. There are a million possibilities when it comes to compression spring design. This is why we’ve provided you with this compression spring dimension measurement guide.

There are three primordial dimensions which are linked to each other. One dimension depends on the other two in whichever order you put it. These are:

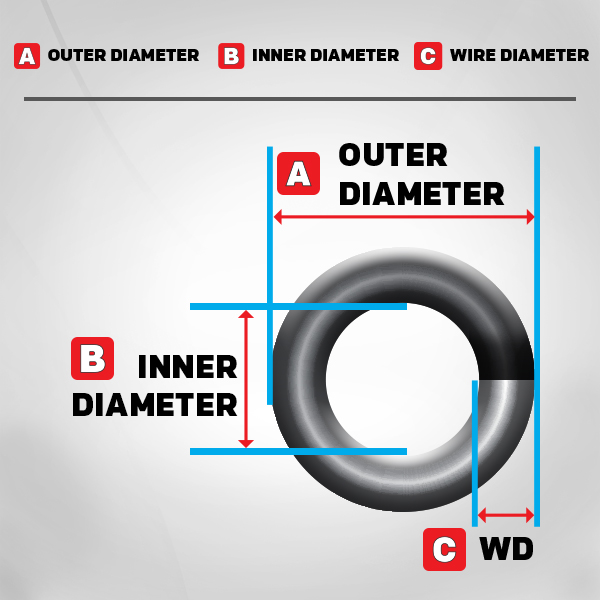

Diameter is a circle’s width at its widest position, right across the middle. The outer diameter is measured from the outside of the coil’s width while the inner diameter is measured from inside of the coil. The wire diameter is simply the wire thickness. These all depend on each other because changing one dimensions will also change the other dimensions. Making the wire diameter larger could decrease or increase the outer and inner diameters, and changing either diameter will affect the other diameter unless the wire diameter is also adjusted.

Another physical dimension that you’ll need is:

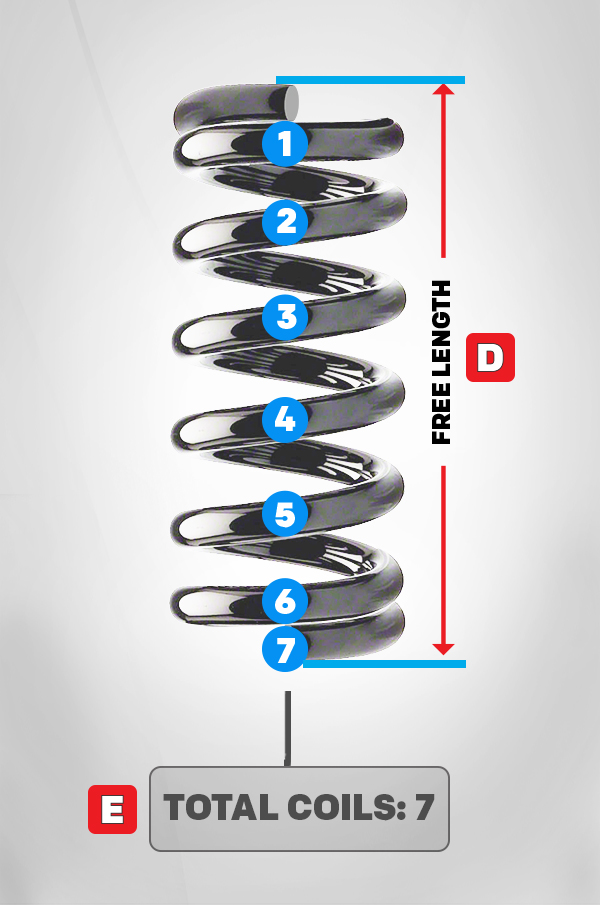

In this case you must consider the length of the space where your spring will be placed from the base of the spring to the second object that’ll be pressing on top of it. If your spring will be pre-loaded, make sure you make the length a little bit longer. Knowing the free length will help you determine how much travel your spring will have to compress.

Along with the free length of your compression spring design you need to know the amount of

Active coils will help you determine your spring’s force and elastic limit when you get to calculating spring rate and safe maximum travel. We refer to them as active coils because, depending on the end type, you will probably have some closed coils on the ends for stability and support thus meaning that you’ll have more total coils than active coils.

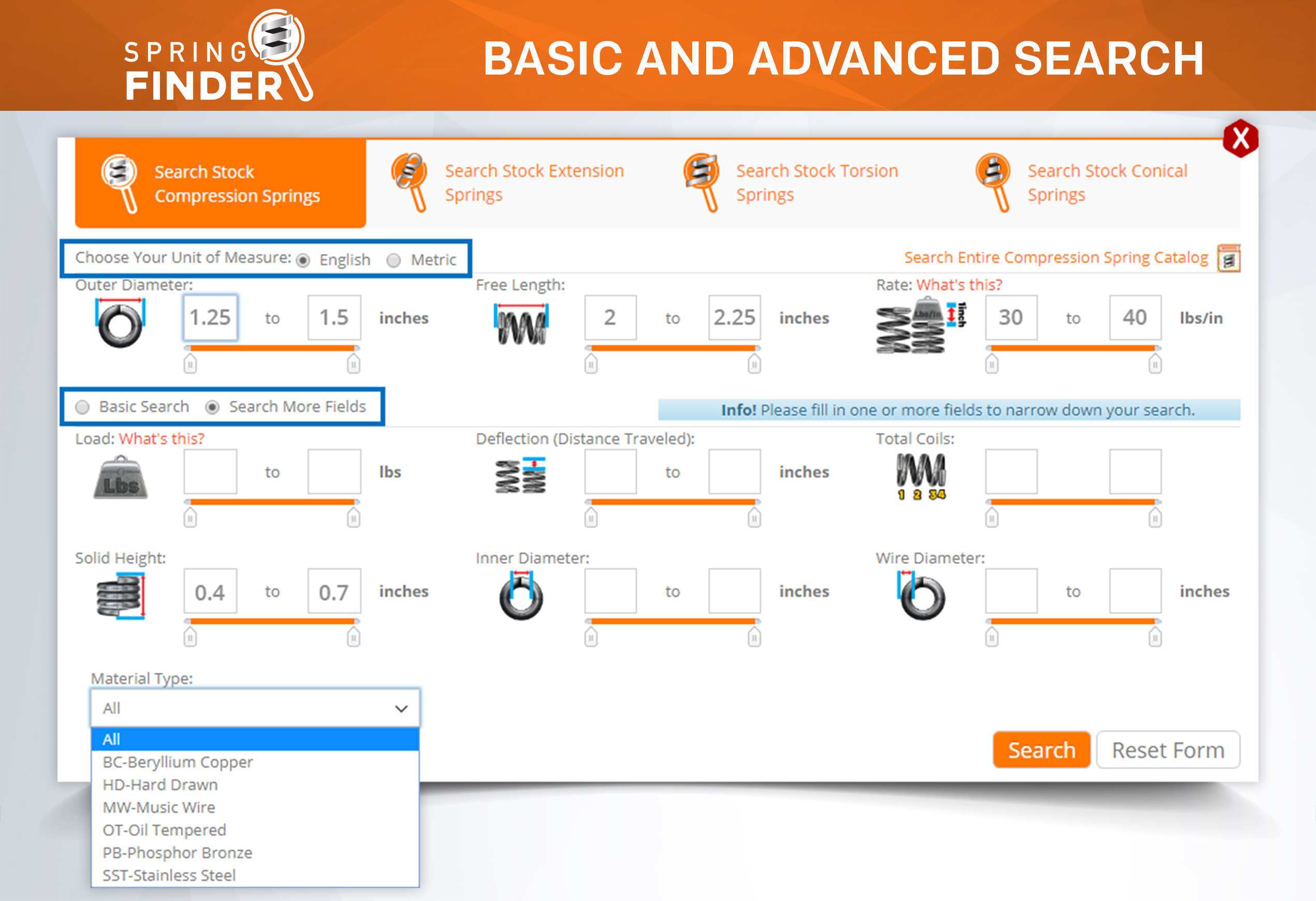

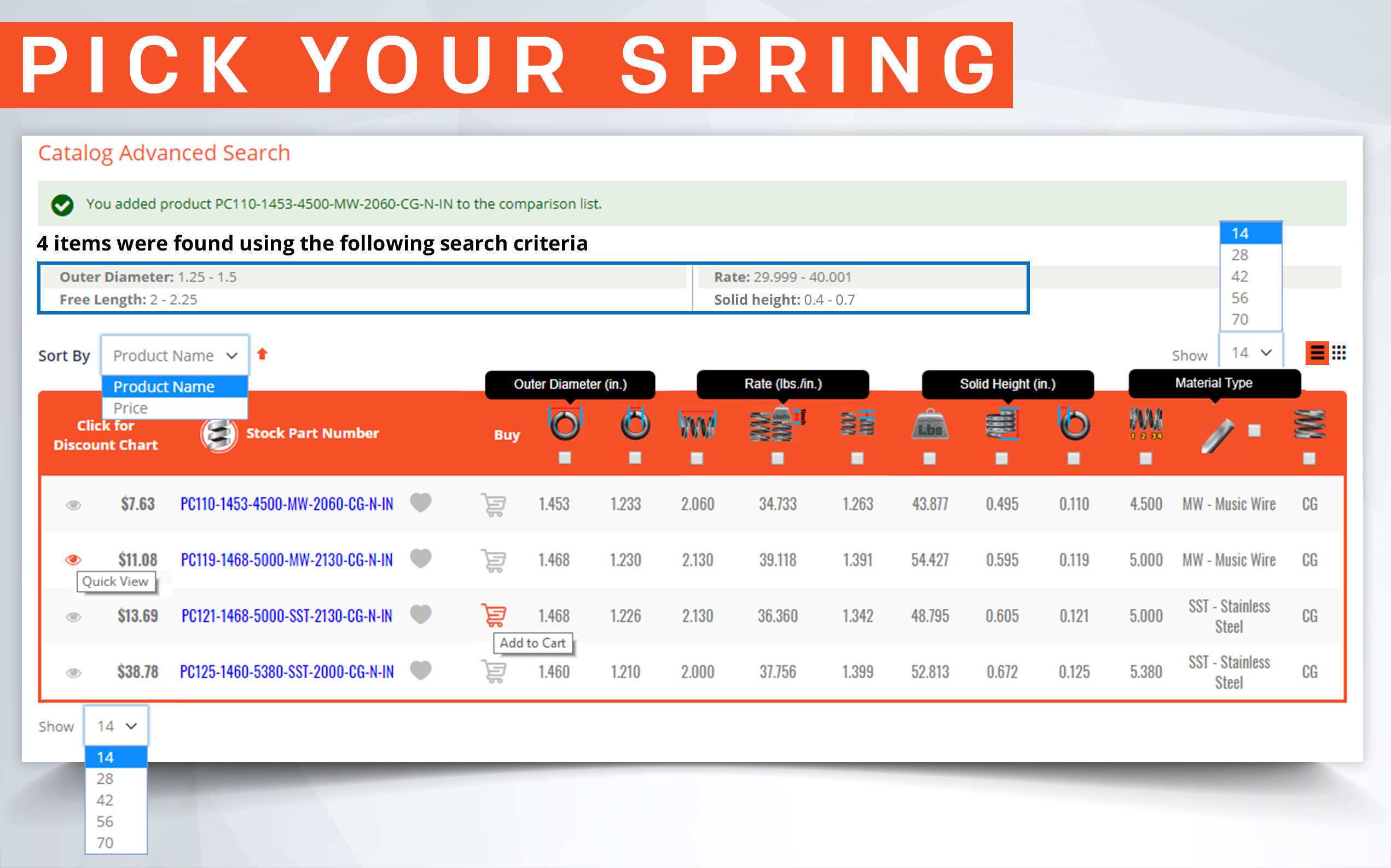

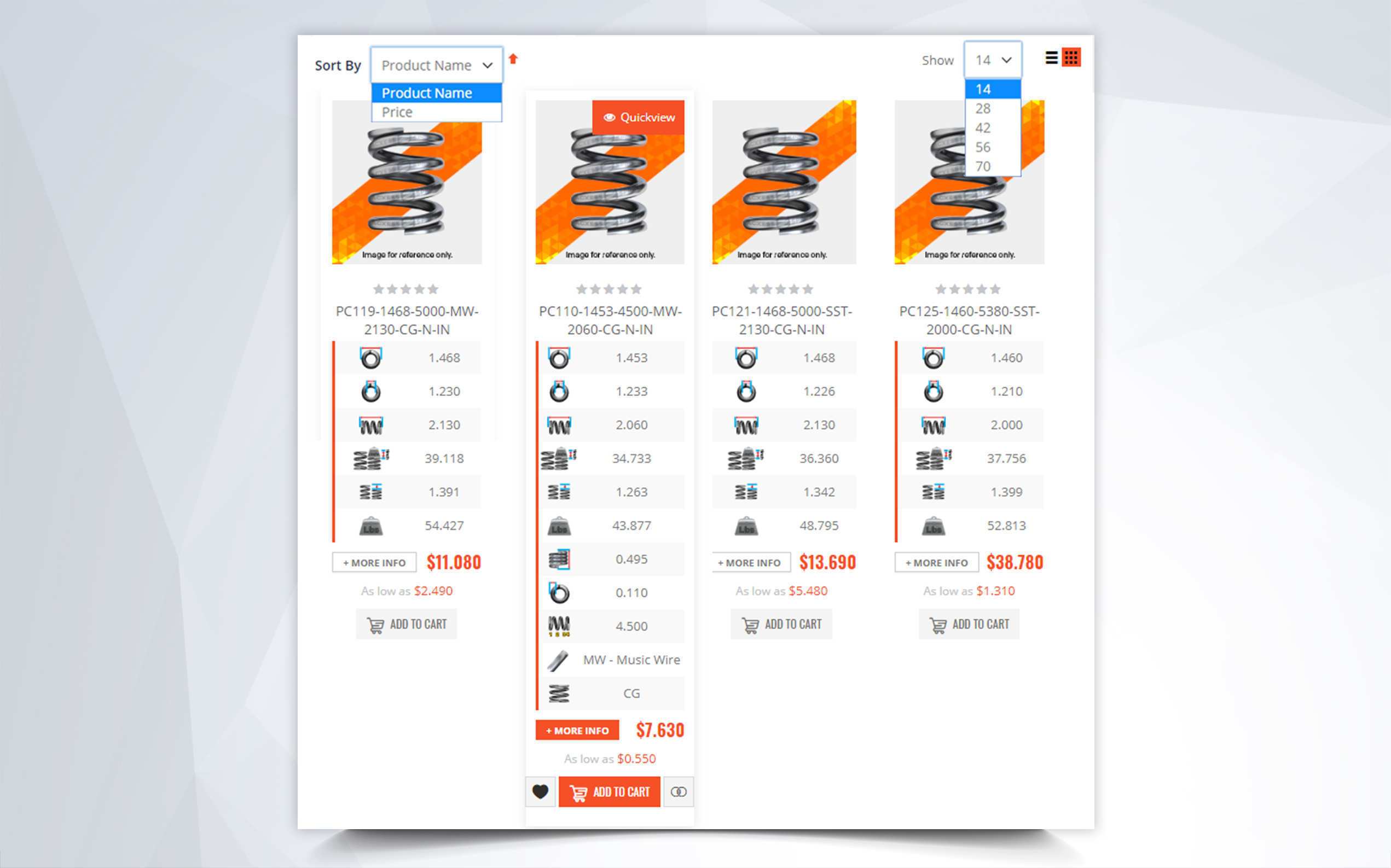

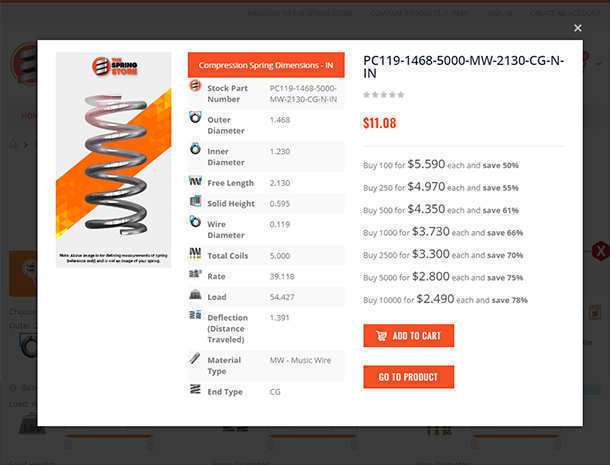

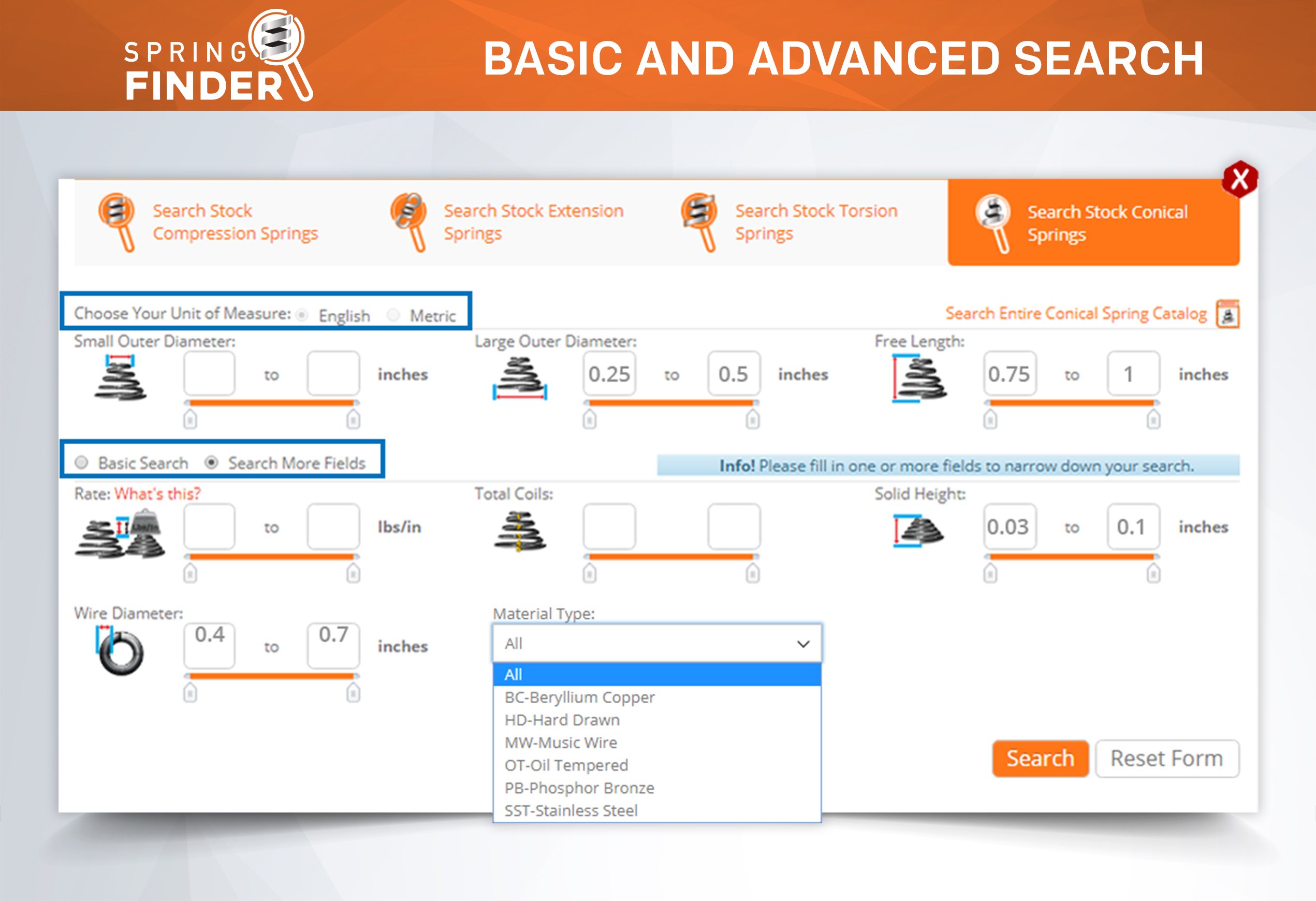

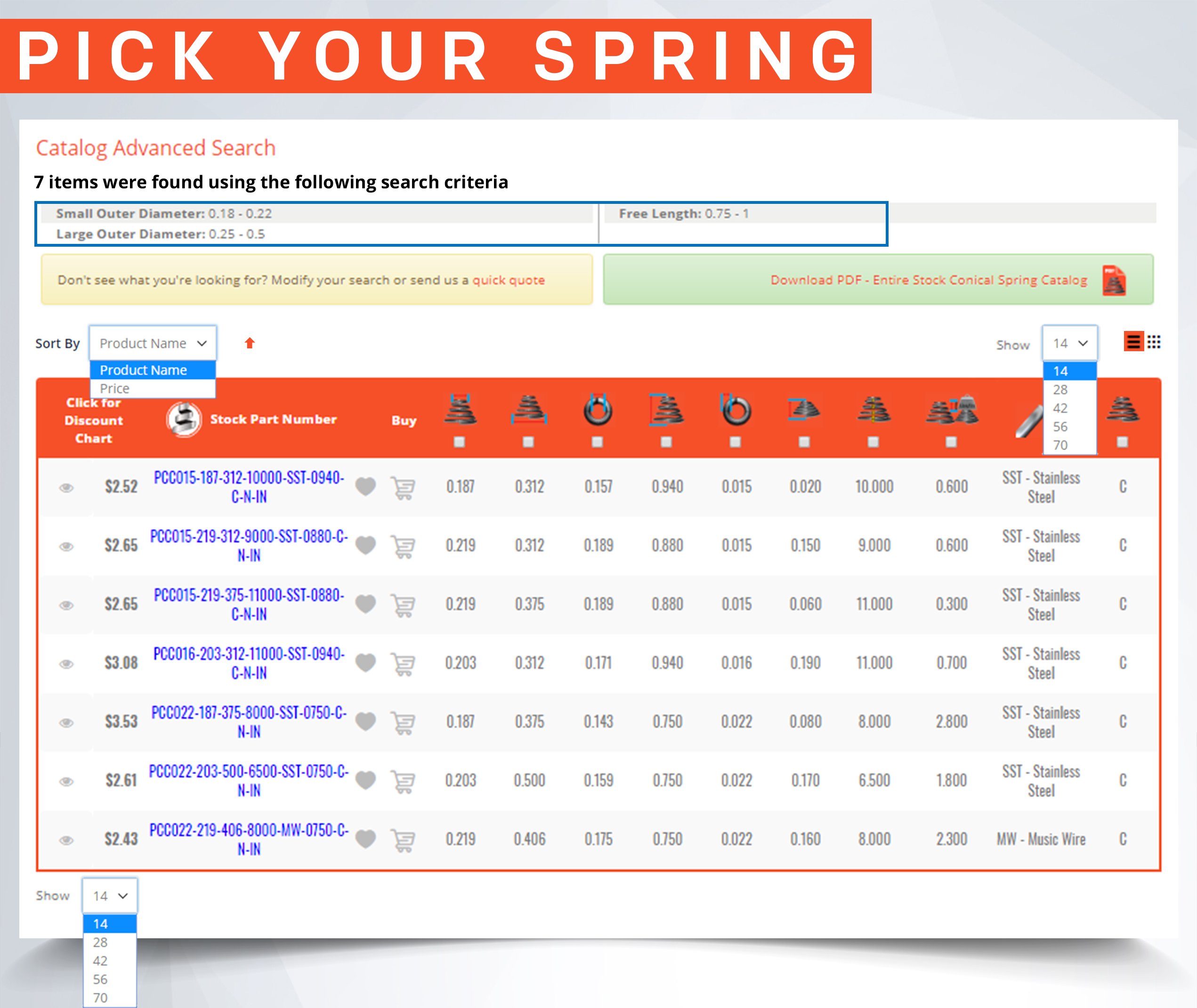

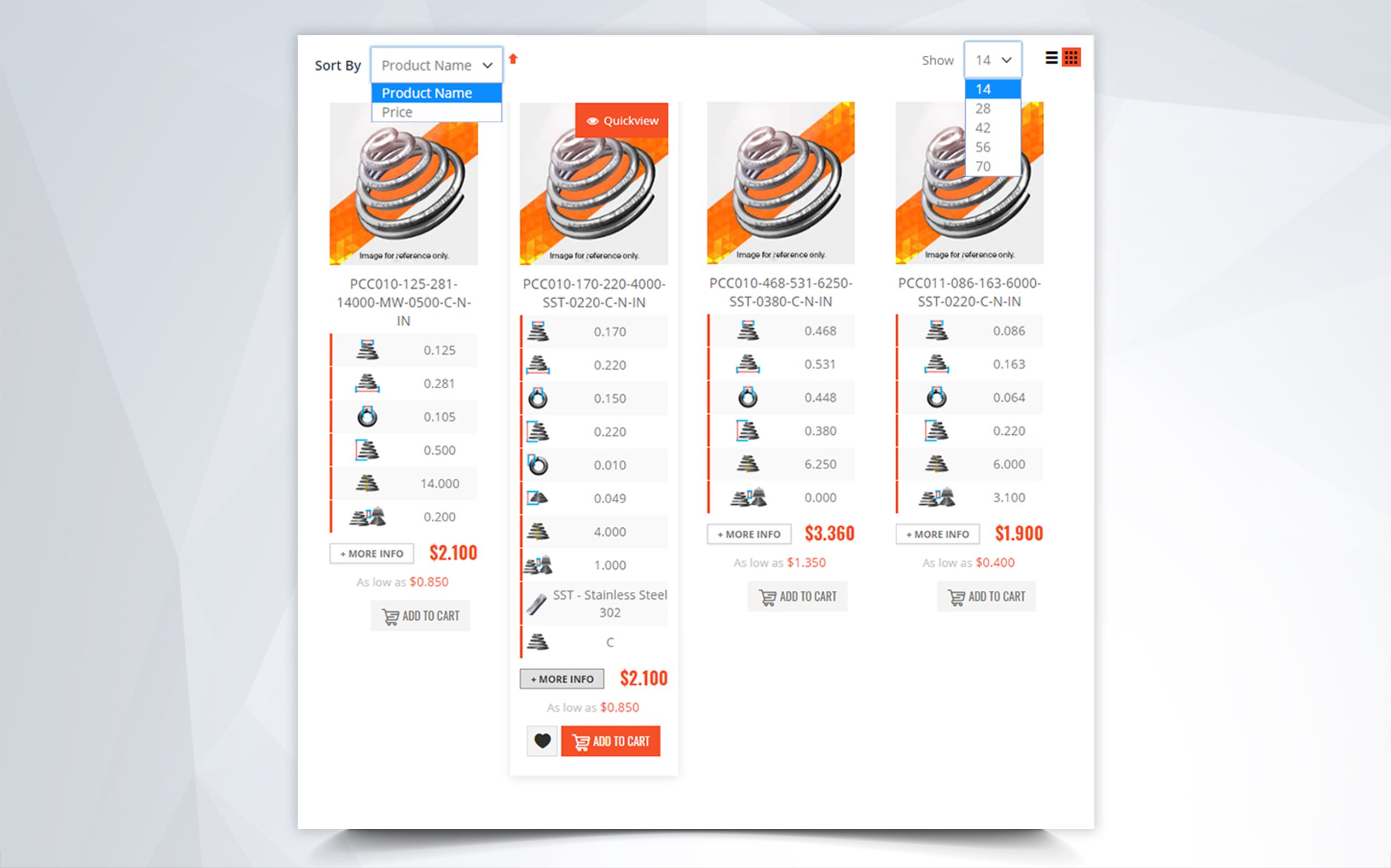

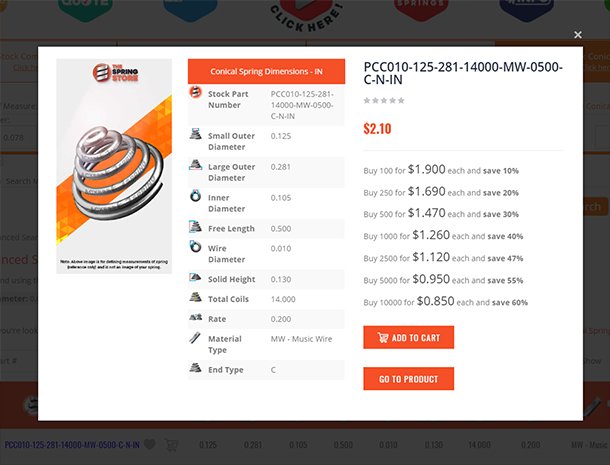

To begin a compression spring design, visit our free, online spring calculator. Once you’re satisfied with your design you may buy similar stock springs or have them manufactured in those real time dimensions by purchasing them through the instant spring quote also provided on our spring calculator.

Compression Spring End Types