Springs in the Mars Rover: A Leap in Space Exploration Technology

Springs in the Mars Rover:

A Leap in Space Exploration Technology

Introduction

The Mars Rover, embodying decades of innovation and exploration, showcases the pinnacle of space engineering. Within its complex mechanisms, springs play a vital yet often underappreciated role, critical for both the rover's mobility and the instruments it carries. This article aims to highlight the essential function and development journey of springs within the Mars Rover project, providing insights into the challenges faced and the innovative solutions devised. It's a narrative that extends beyond mere mechanical components, touching upon the broader implications for space exploration and the potential applications back on Earth. Designed for a diverse audience, from industry professionals to science enthusiasts, this exploration seeks to demystify the intricate dance between physics, engineering, and the unforgiving Martian environment.

The Story of Development

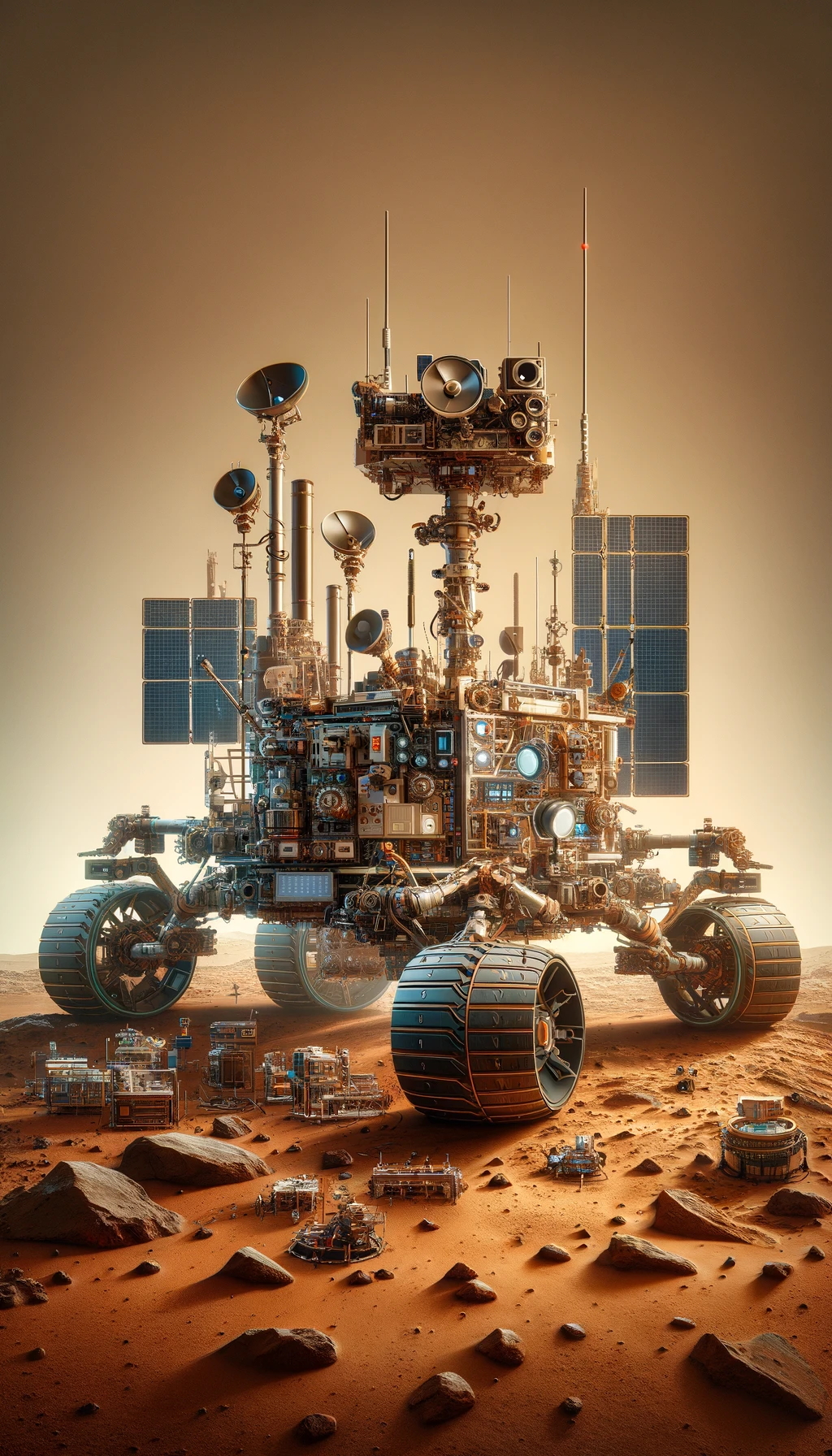

The evolution of the Mars Rover and its integral spring components is a narrative marked by relentless innovation and adaptation. This story begins with the Pathfinder mission in the late 20th century, introducing the Sojourner rover, and extends through the Spirit, Opportunity, and the more recent Curiosity and Perseverance rovers. Each mission built on the successes and lessons of its predecessors, pushing the boundaries of what was technically feasible.

Initially, the challenge was to create a mobile platform capable of conducting scientific research on the Martian surface. Early rover designs had to be lightweight yet durable enough to withstand the journey to Mars and the harsh surface conditions. Springs played a critical role in this equation, tasked with providing stability and shock absorption to protect sensitive scientific instruments and ensure the rover's mobility across uneven terrain.

As the missions evolved, so did the complexity of the rovers' objectives and, consequently, their designs. The introduction of the Rocker-Bogie suspension system in the Sojourner rover set a new standard for mobility and stability, using coil springs in an innovative way to maintain balance and traction. However, it was with the Spirit and Opportunity rovers that the design and application of springs truly began to mature, reflecting a deeper understanding of Mars' geological variability.

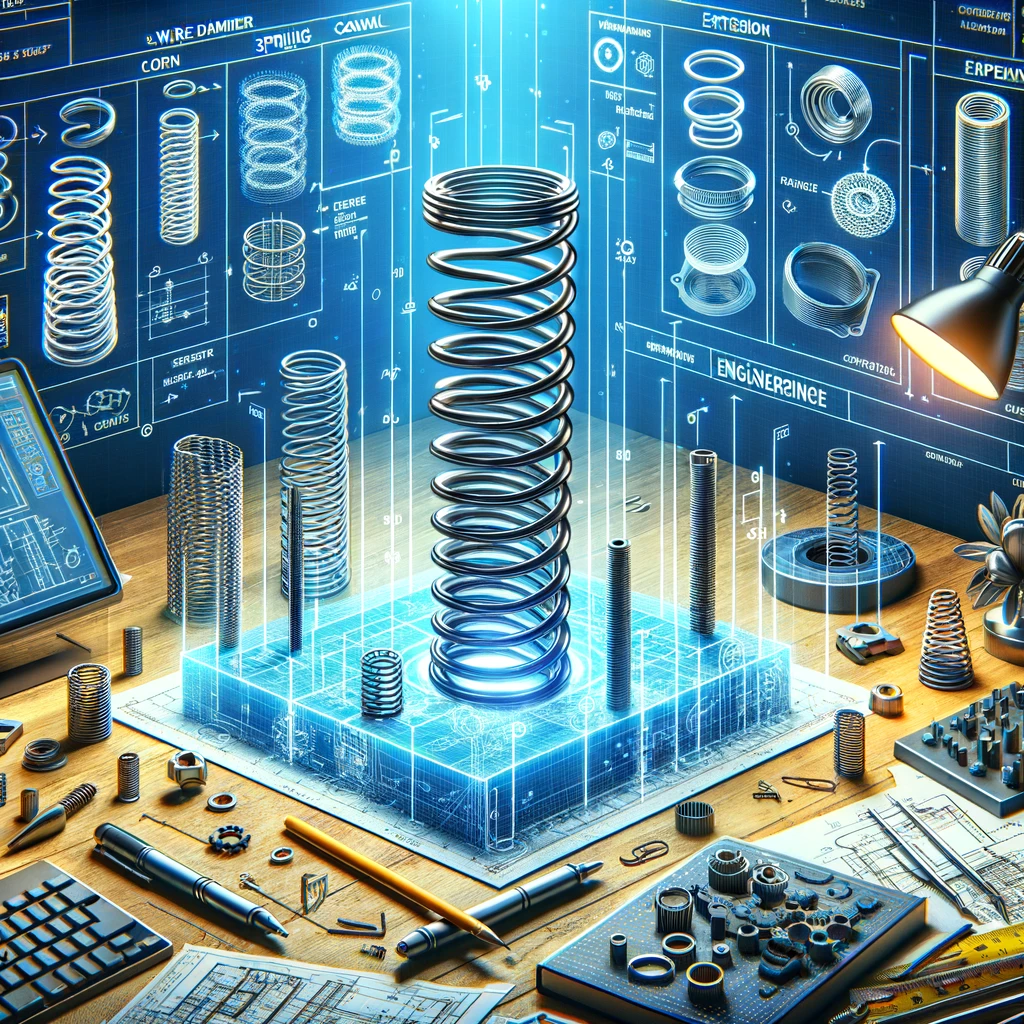

The development process for these springs entailed rigorous testing and simulation, much of it conducted on Earth in environments crafted to mimic Martian conditions. Engineers faced the daunting task of ensuring that these springs could perform under a range of scenarios, from climbing rocky outcrops to crossing sandy plains. Materials had to be carefully selected for their durability and ability to withstand temperature extremes, a challenge compounded by the necessity of keeping the rovers' weight to a minimum.

The culmination of these efforts was most vividly seen in the Curiosity Rover, launched in 2011. By this time, the design team had access to advanced materials and a wealth of data from previous missions. The springs used in Curiosity’s mobility system were not only designed for greater durability, but also for enhanced flexibility, allowing the rover to traverse larger obstacles and dig deeper into the Martian soil.

Each step in this developmental journey was marked by collaboration between materials scientists, mechanical engineers, and planetary geologists. They worked in concert to refine the spring mechanisms, ensuring they met the increasingly ambitious goals set for Mars exploration. The iterative design process, supported by cutting-edge engineering tools and extensive field-testing, highlights the meticulous approach required to engineer components for space exploration – where failure is not an option, and every detail matters. This ongoing narrative of development continues to inspire and inform the design of mechanical systems for space and beyond, pushing the limits of what's possible in engineering and exploration.

Challenges and Solutions

Designing springs for the Mars Rover introduced unique challenges, primarily stemming from the extreme temperature fluctuations and the rugged Martian surface. Traditional materials and designs were inadequate, as they could not guarantee the longevity or performance needed for the duration of the mission. Engineers employed advanced materials such as memory alloys that could withstand the temperature extremes without losing their mechanical properties. Utilizing simulation software, akin to Acxess Spring’s 3D CAD tools, they were able to model and iterate on spring designs rapidly, assessing their performance under simulated Martian conditions, which included testing for wear, flexibility, and resistance to temperature changes.

Case Studies:

The Curiosity Rover, in particular, serves as a prime example of innovative spring application in space technology. The Rocker-Bogie suspension system incorporated in the rover exemplifies the integration of coil springs designed for optimal energy absorption and terrain adaptability. The development of this system was a complex process, involving rigorous testing in simulated Martian environments here on Earth. Engineers had to ensure that the springs could support the rover's weight, enable mobility across diverse landscapes, and survive the harsh Martian nights. The success of this system has not only been instrumental in Curiosity's scientific achievements, but also in demonstrating the viability of such spring mechanisms for future extraterrestrial missions.

Innovations in Spring Technology

The Mars Rover project has catalyzed significant innovations in spring technology, particularly in the realms of material science and mechanical design. The adoption of non-linear coil springs, which offer variable resistance levels, was a breakthrough, enabling the rovers to navigate over obstacles more effectively. Furthermore, the exploration into composite materials for springs opened new avenues for lightweight yet robust design solutions. These advancements were propelled by the integration of cutting-edge design tools, allowing for a granular examination of potential stresses and strains that the springs would encounter, leading to highly optimized components suitable for the harsh Martian terrain.

Application and Impact

The successful application of advanced spring mechanisms in the Mars Rover has had far-reaching impacts, extending beyond space exploration. The technologies developed have potential applications in various Earth-bound industries, including automotive, aerospace, and even consumer electronics, where conditions demand robust and reliable mechanical solutions. The lessons learned from the Mars Rover project highlight the importance of interdisciplinary collaboration and the continuous push for innovation in addressing complex engineering challenges.

Conclusion

The Mars Rover's springs are more than mere components; they are a testament to human ingenuity and the relentless pursuit of discovery. The journey from conceptualization to deployment on Mars encapsulates a broader narrative of problem-solving and innovation that transcends industries. For professionals in the field, the Mars Rover serves as both inspiration and a case study in overcoming environmental and operational challenges through advanced engineering. By harnessing tools like Acxess Spring's CAD software and Online Spring Force Tester, the boundaries of mechanical design and application continue to expand, paving the way for future innovations both on Earth and in the cosmos.