Compression Spring Max Deflection

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Definition: The elastic limit is the maximum amount of load and deflection (travel) you are to expect out of a compression spring without risking it taking a permanent set.

Load and travel are relative to each other based on the spring rate. This is why both values are included in the definition. Learn how the elastic limit works to understand your compression spring design.

One would think that you can push compression springs down to the point where all of the coils are touching (solid height) but this is not always true. Compression springs have an elastic limit. This is the limit as to how far they can go without being damaged. In some instances compression springs can reach solid height but not always as it depends on the rest of the dimensions in the design. If your spring is under a lot of stress, it will have low elasticity (meaning a small amount of travel) thus not being able to fully compress.

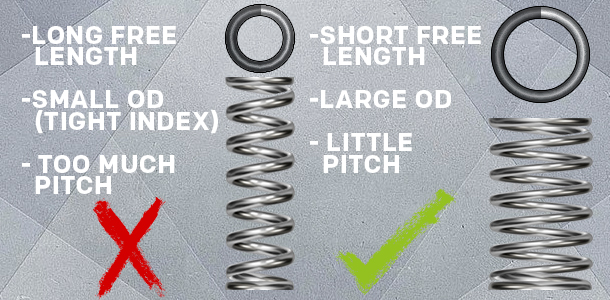

You determine if your spring is stressed based on the tightness of the spring’s coil diameter and/or the proportion between the active coils and the pitch (space in between them).

To know the tightness of your spring’s coil diameter, you must calculate the spring index. Spring index is the proportional ratio between the wire diameter and the outer diameter. First, you calculate mean diameter by subtracting one wire size from the outer diameter or adding the wire size to the inner diameter. Once you’ve calculated the mean diameter, you divide it by the wire diameter. If the result is about 5 or less, your spring’s coils are tight.

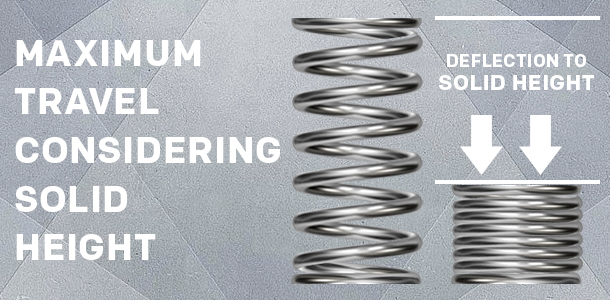

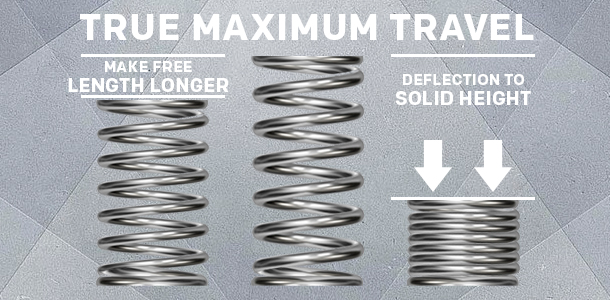

Using our spring calculator, Spring Creator, you will see two different values for travel. One (usually the higher one) is the max potential travel. This means that, with the current proportion of your dimensions, if you make the free length longer, you will achieve more travel (thus more load). The other value is the max safe travel considering solid height. This is the amount of travel you are able to get out of your current design. If both values are the same, you are using your spring’s full potential travel but may not always be able to travel down to solid height.

Whether you can travel to solid height or not can be determined by subtracting it from the free length and then comparing the result to the max safe travel considering solid height. If the result is the same, you can travel to solid height. If not, you simply won’t.

If you need more max safe travel you will need to add more coils, increase your outer diameter, or change the material type to a softer one. This will weaken your spring rate. To compensate, you need to thicken your wire diameter. If you decide to change the material type, you can go from Hard Drawn to Music Wire, from Oil Tempered to Chrome Silicon, or from Stainless Steel 302 to Stainless Steel 17-7.

In an extreme case, you can reduce your solid height by switching to open or ground ends. Switching to ground ends will eliminate 2 wire diameters halves (one wire total). If you switch to open ends, you will eliminate the two closed coils at the ends thus eliminating 2 wire sizes. The last option you have is to select open ended coils with ground ends. This will eliminate 1 more wire diameter thus giving a bit more travel.

Use our tools to figure out either if your spring will meet your required working loads or to find stock springs that do. If you’re having a hard time designing or finding stock compression springs, feel free to contact our team of experts!