What Are Open Wound Springs?

Open wound springs are springs that are manufactured with pitch in between its coils. This creates an open space between the coils, hence the name.

The function of an open wound spring is to compress and store energy. When the force that is applied to it has been lifted or removed the spring then returns to its original position and releases such energy. There are several types of open wound springs. The following are some of the most common subtypes of Open Wound Springs.

Open Wound Helical Springs

The base design of all the different types of open wound springs comes from compression springs. Compression springs have a cylindrical shape; for this reason, they are also known as helical springs. They have pitch in between the coils and are the most common and economical type of spring. The ends of an open wound compression spring have variations between a certain number of closed wound coils to provide stability or open wound coils to provide more travel.

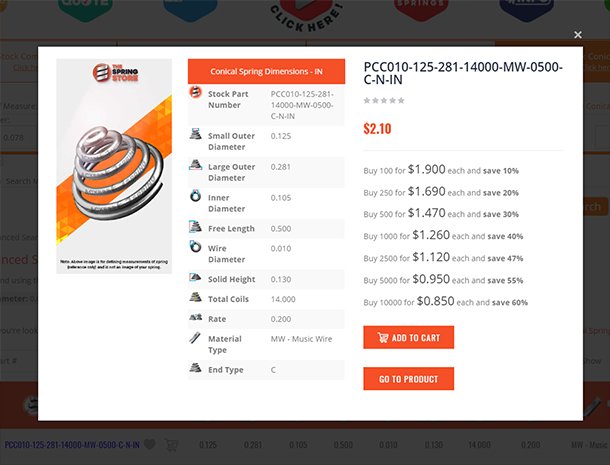

Conical Open Wound Springs

Conical open wound springs are just like compression springs except for the diameters of the spring’s body. These are arranged in a manner that creates a cone shape. These springs commonly have this shape in order to provide stability. This is especially helpful in cases where a normal compression spring runs the risk of bending or buckling due to a high slenderness ratio. Conical open wound springs are also used to reduce solid height since the coil diameters may be adjusted to the point where the conical spring will telescope and use up very little room when compressed.

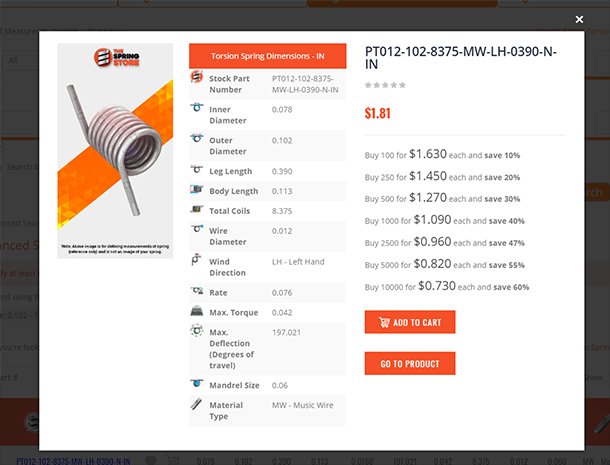

Open Wound Torque Springs

Torsional springs are usually closed wound because they are required to produce torque. In fact, torsion springs, also known as torque springs, are normally classified as close wound springs. However, there are rare but important exceptions and we want to address that here. In the rare case that a torsion spring is required to do more than just torque and its functionality requires it to compress as well, it can have open wound coils. In this case, it usually needs to be custom manufactured but it is doable. The manufacturer will need to adjust the spring design to account for a certain level pitch (space between the coils). This pitch in between that torsional spring’s coils is what helps it become an open wound spring.

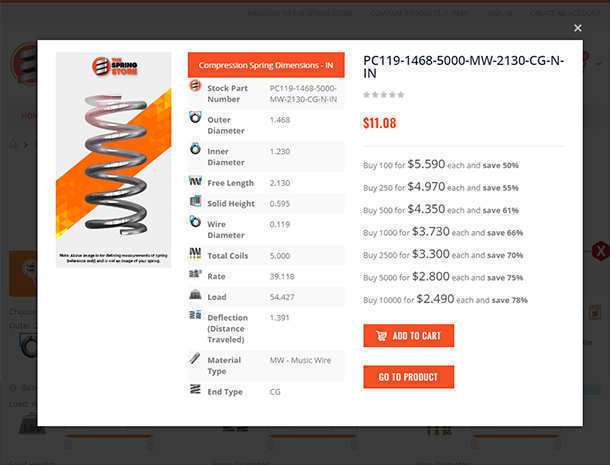

Find and Buy the Right Open Wound Spring

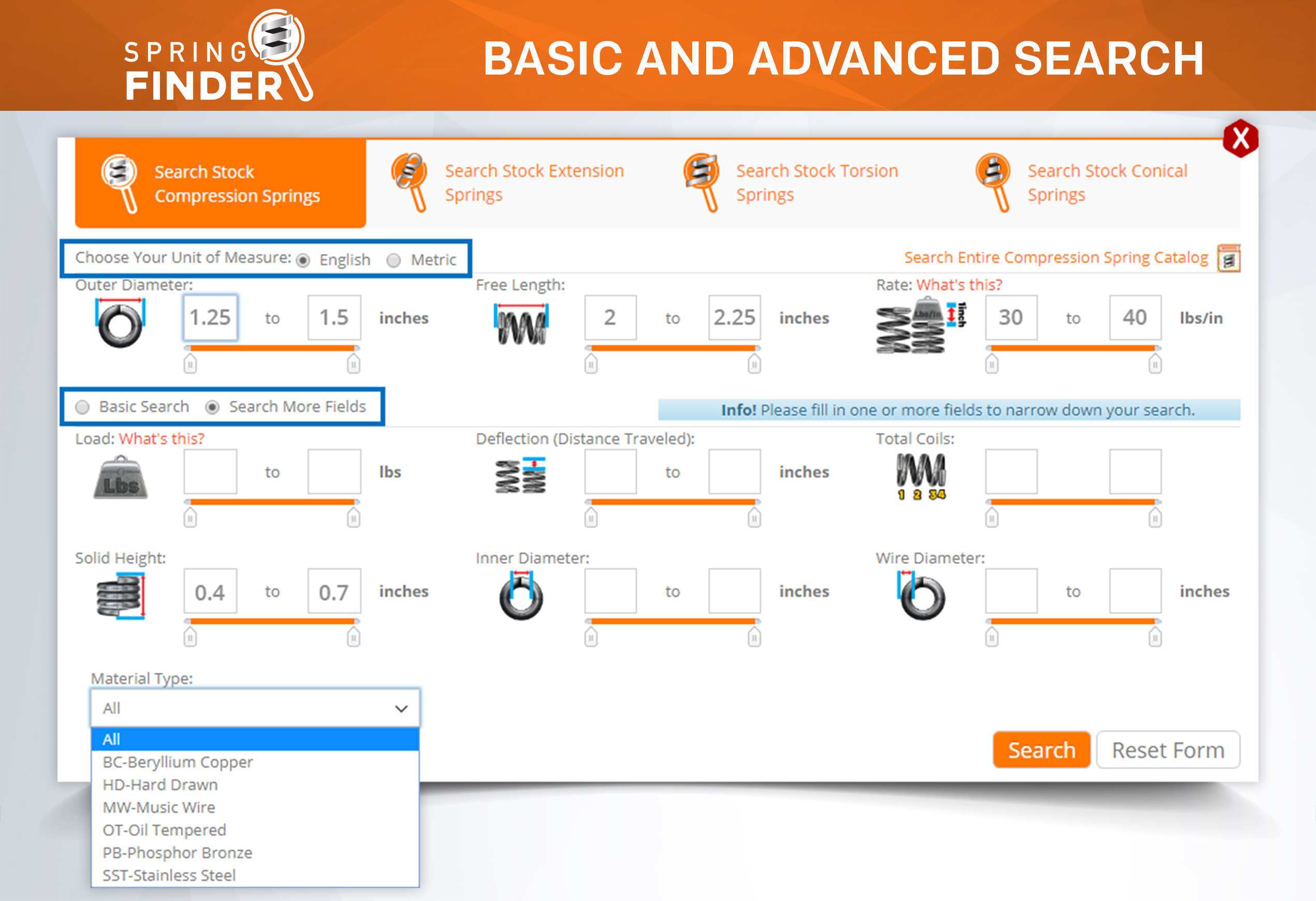

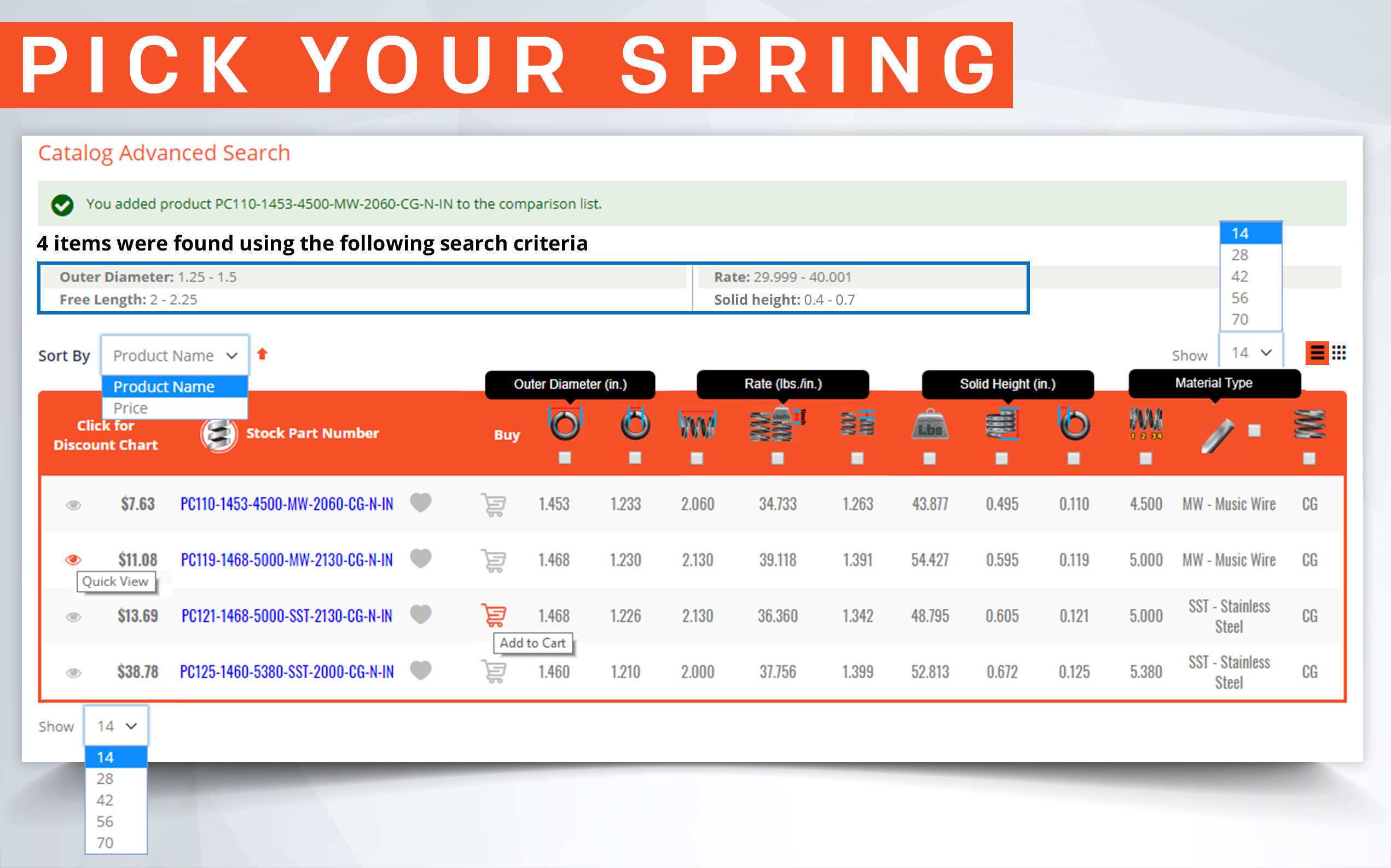

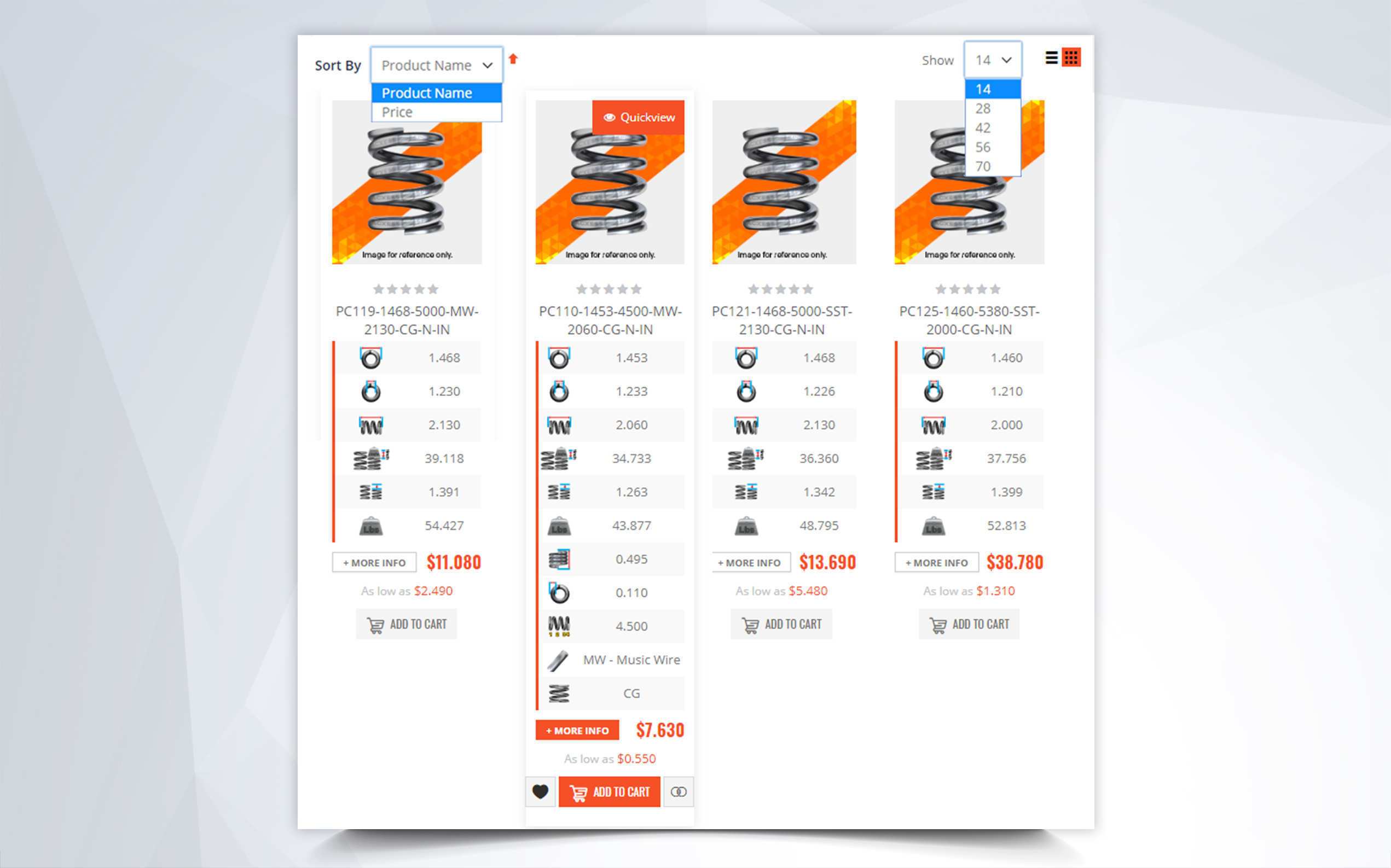

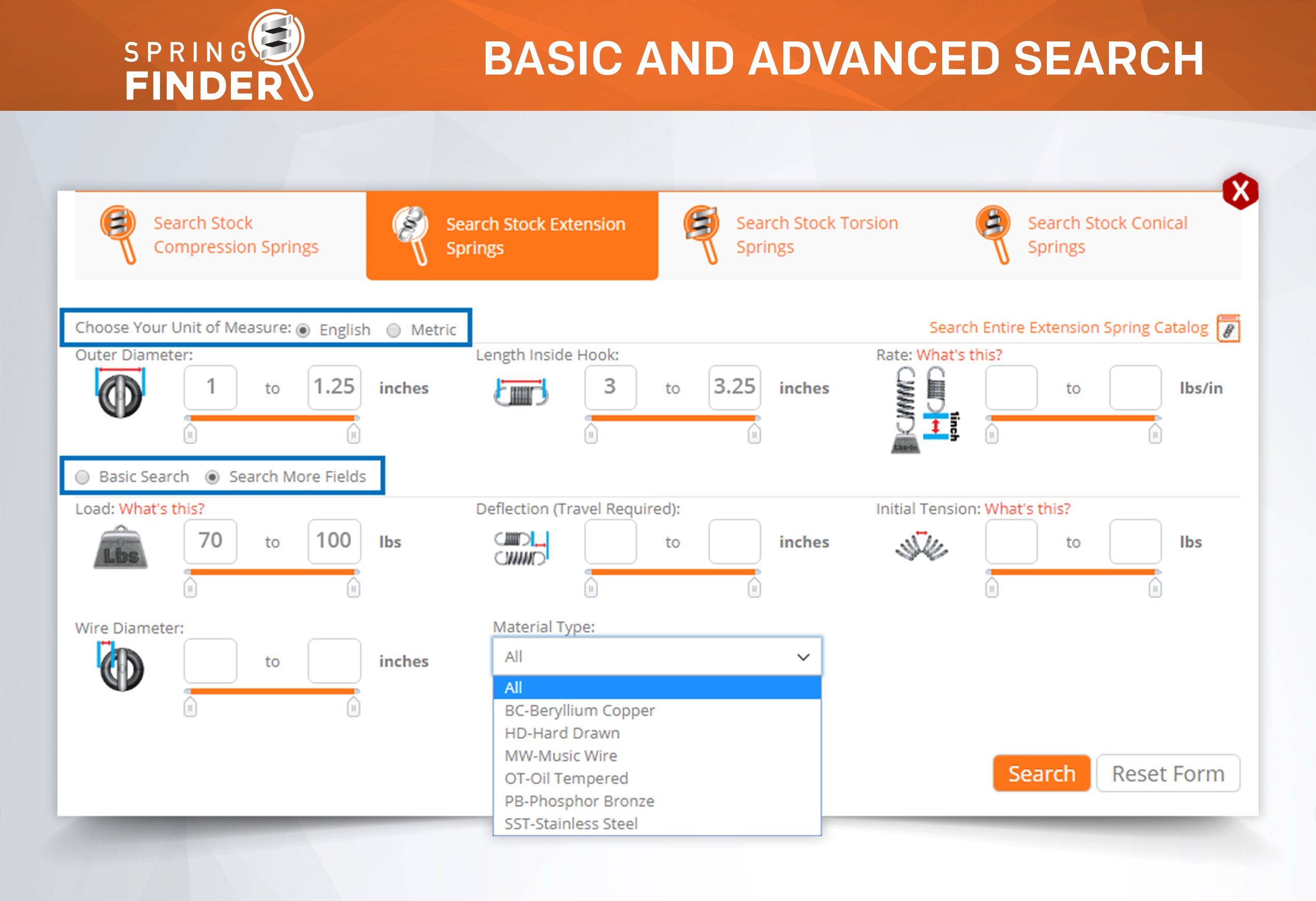

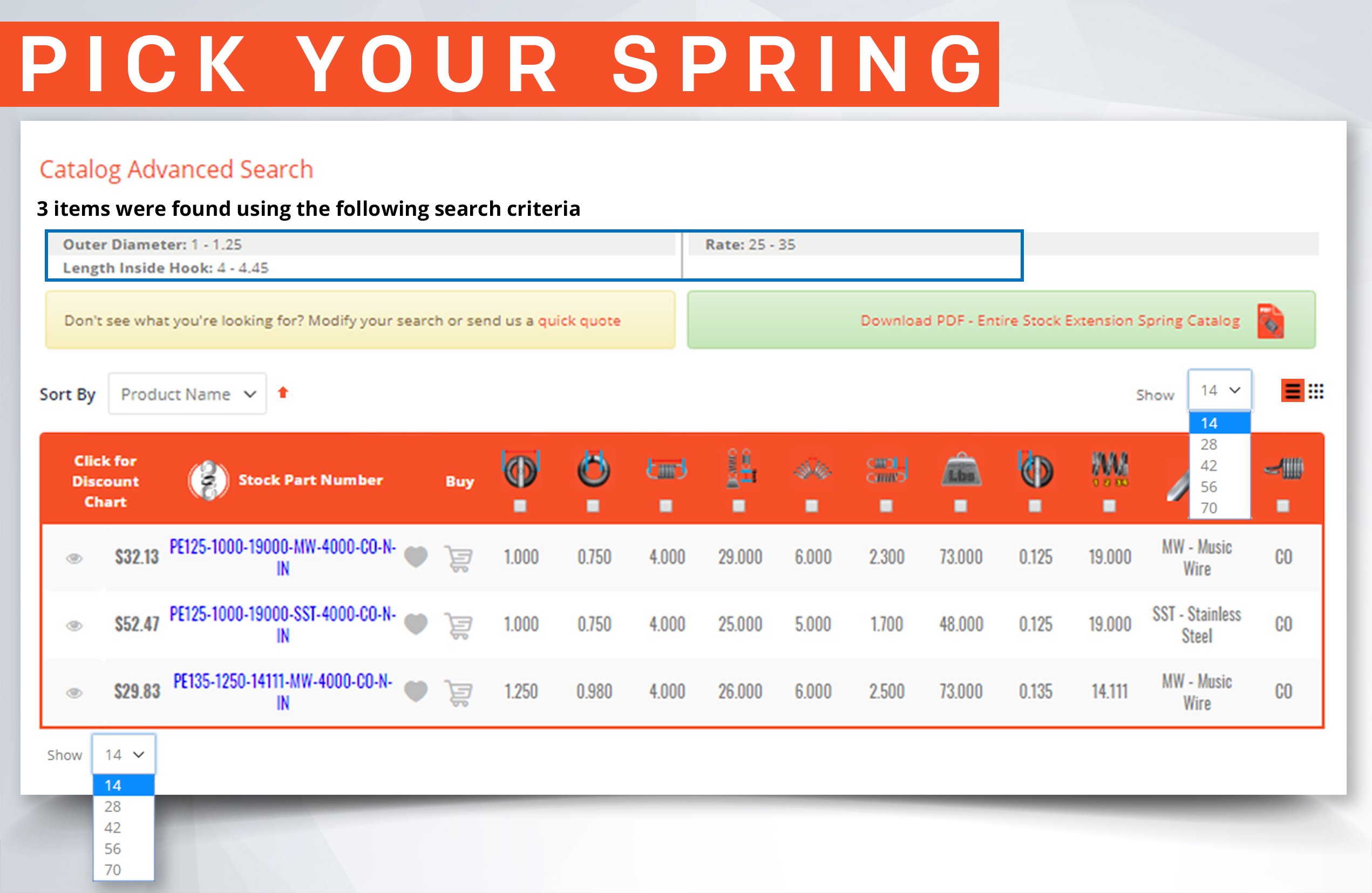

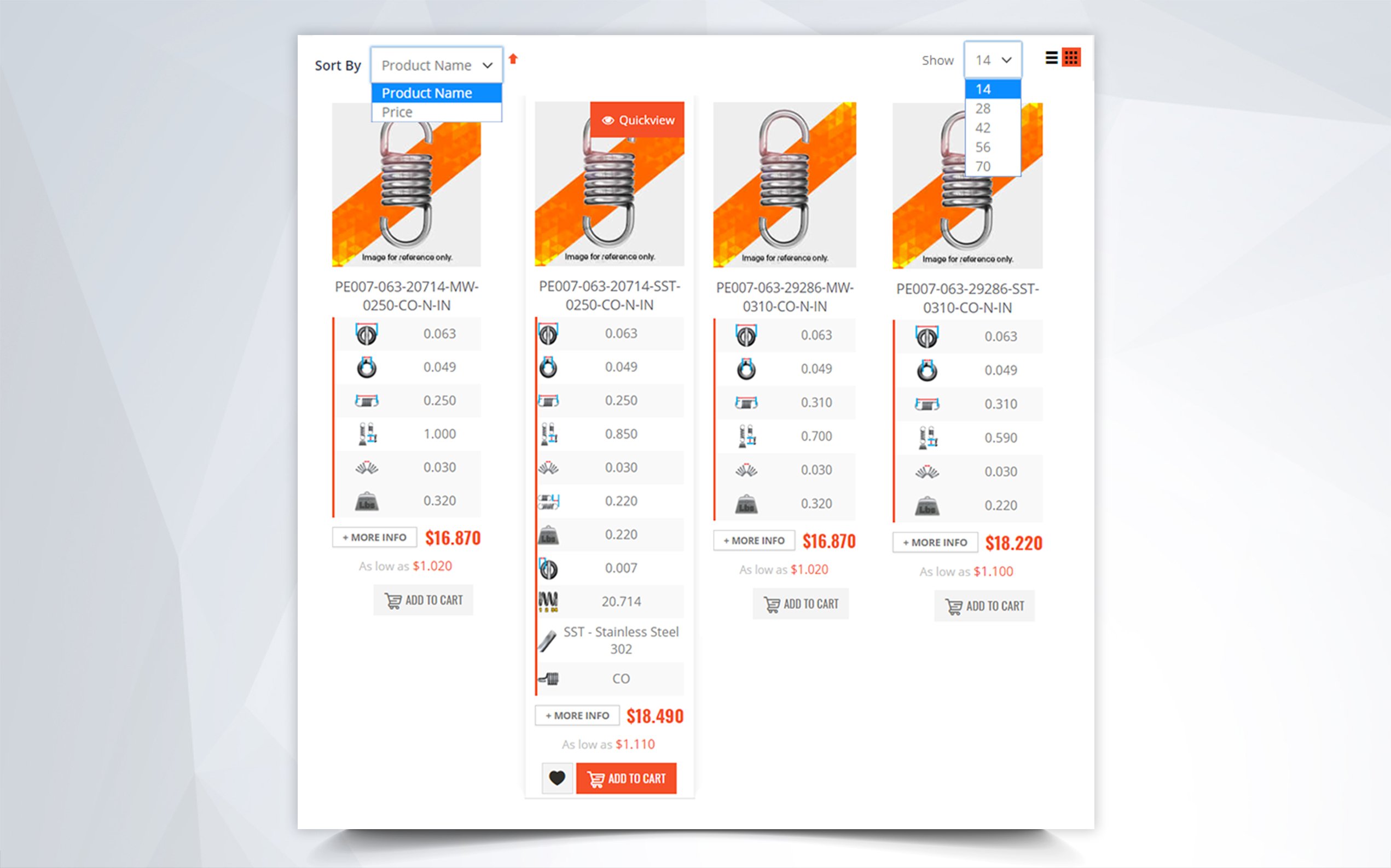

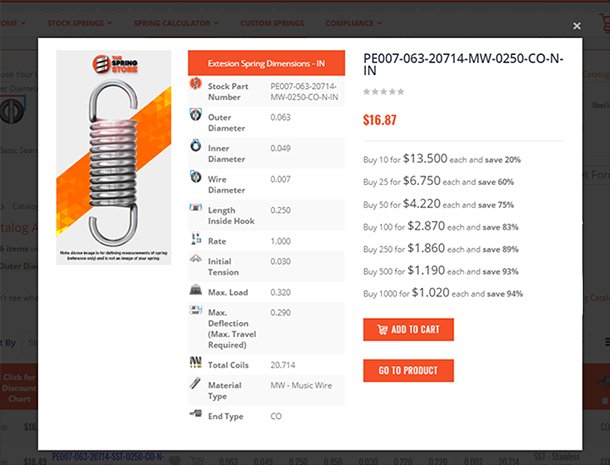

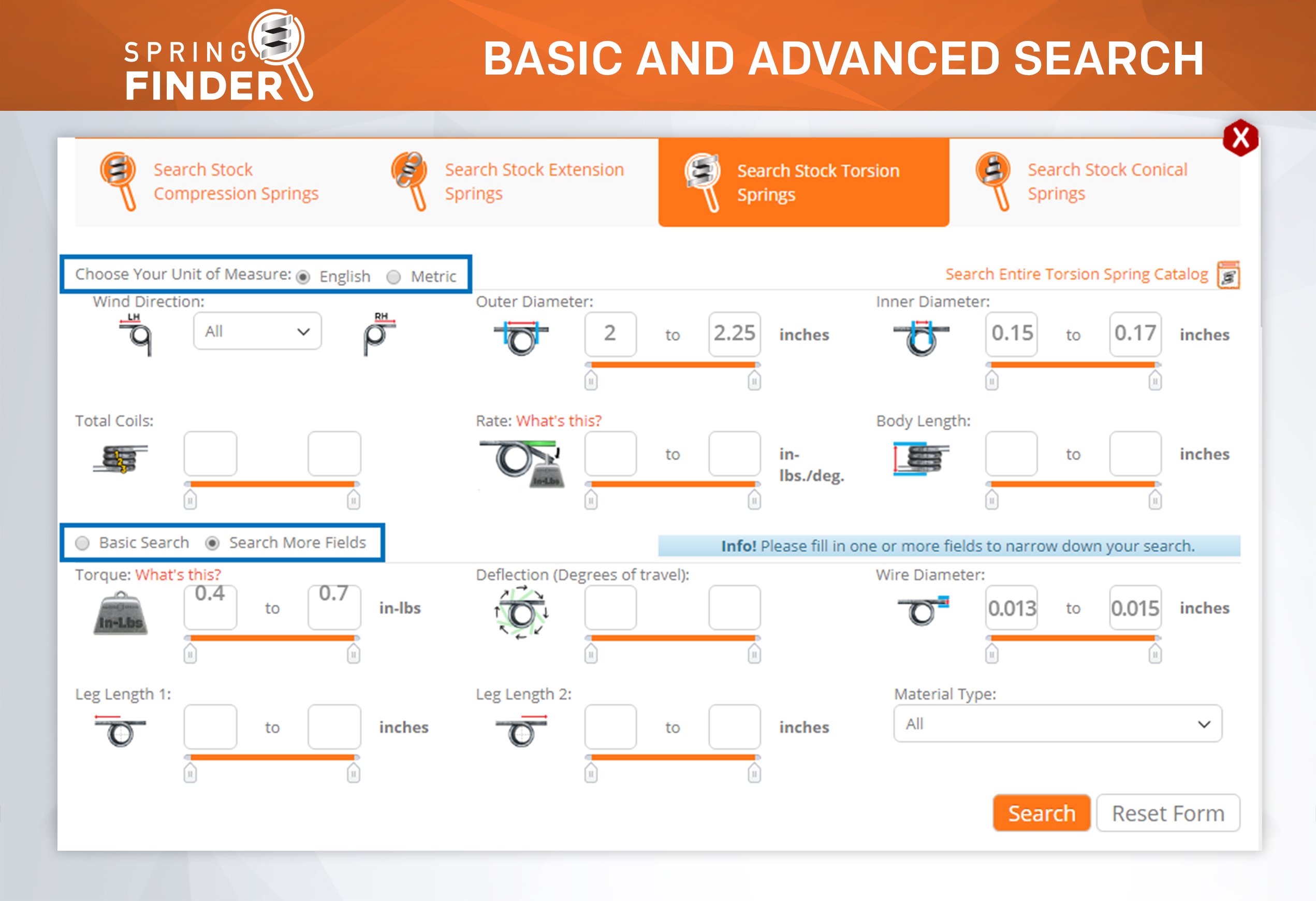

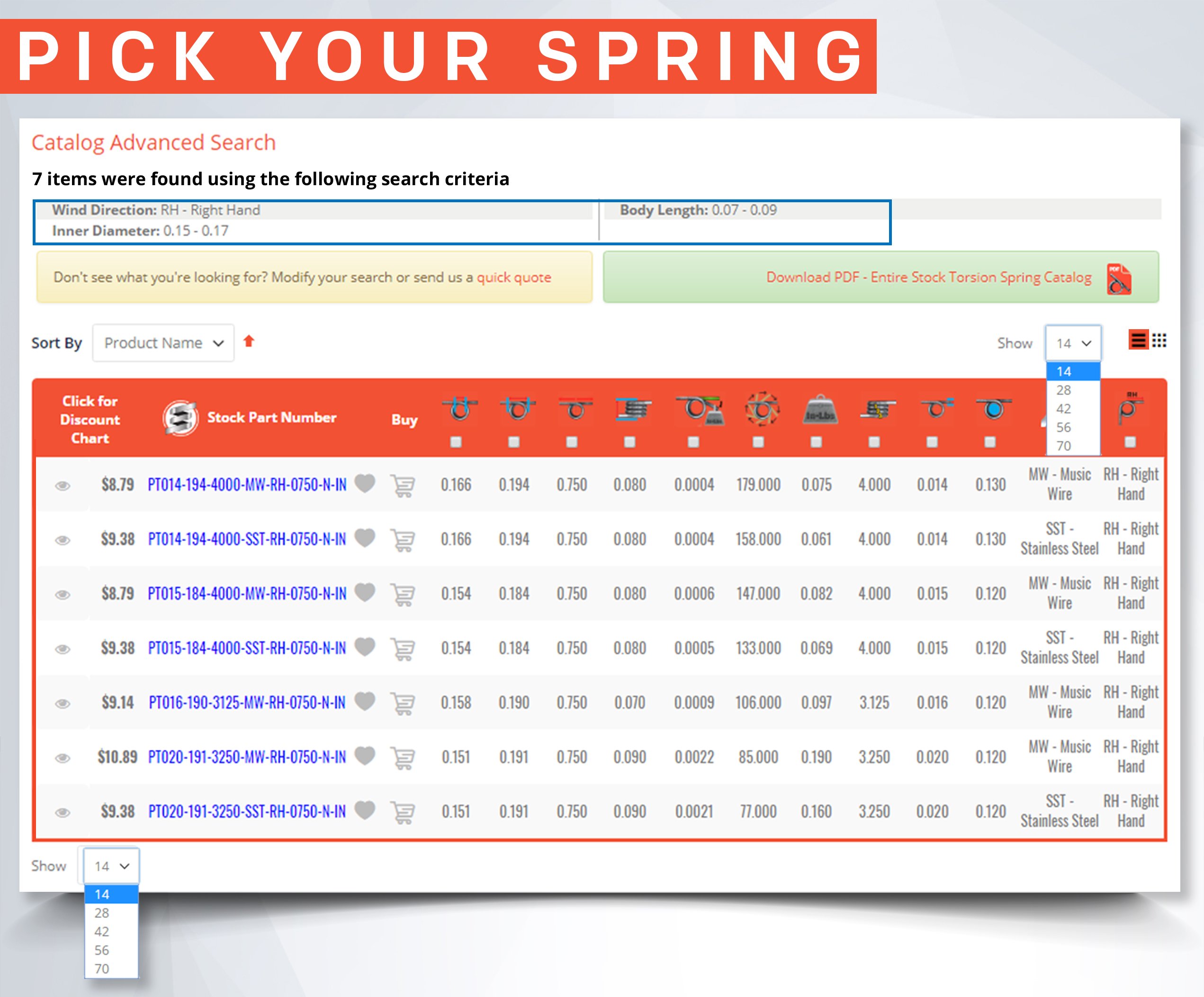

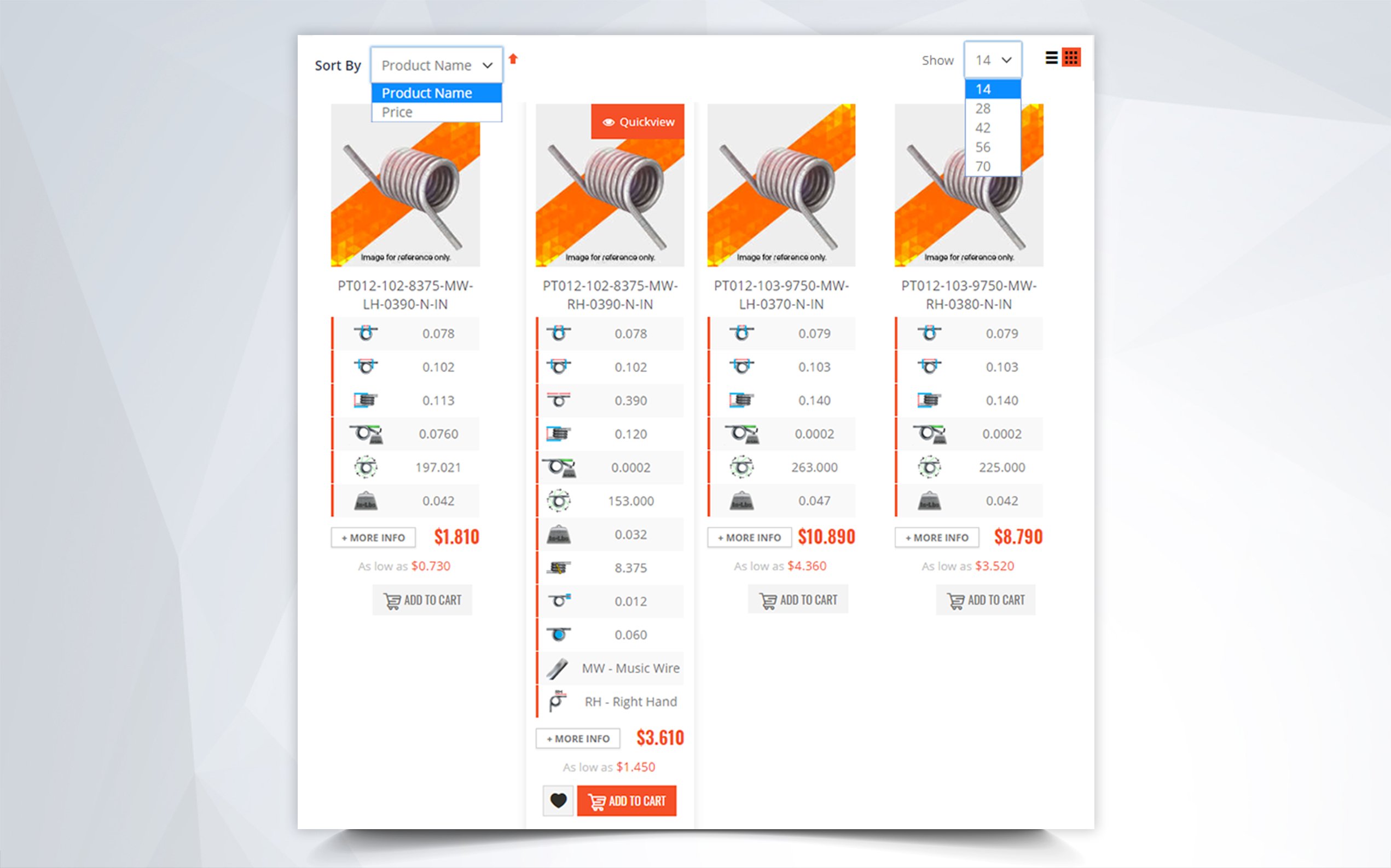

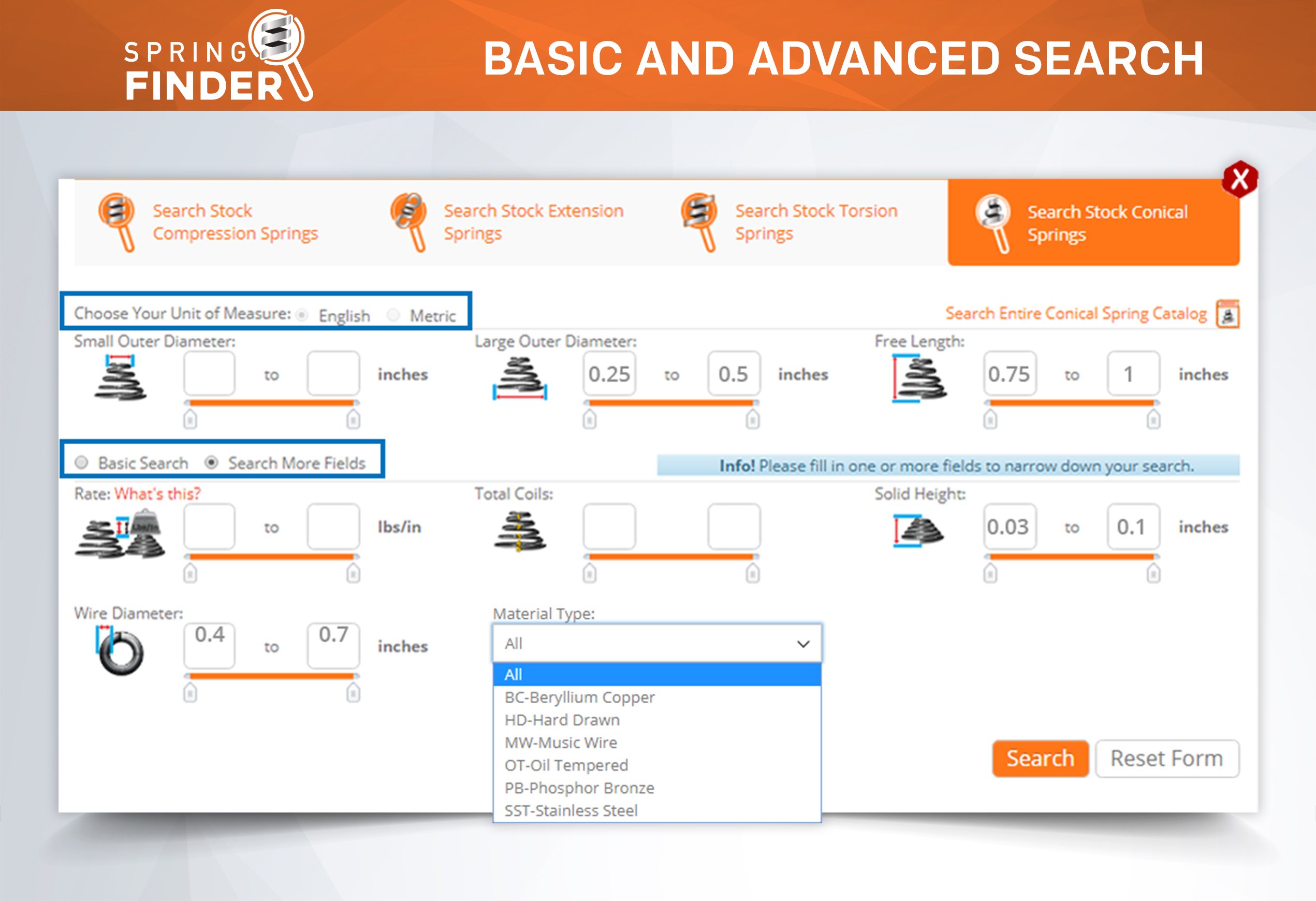

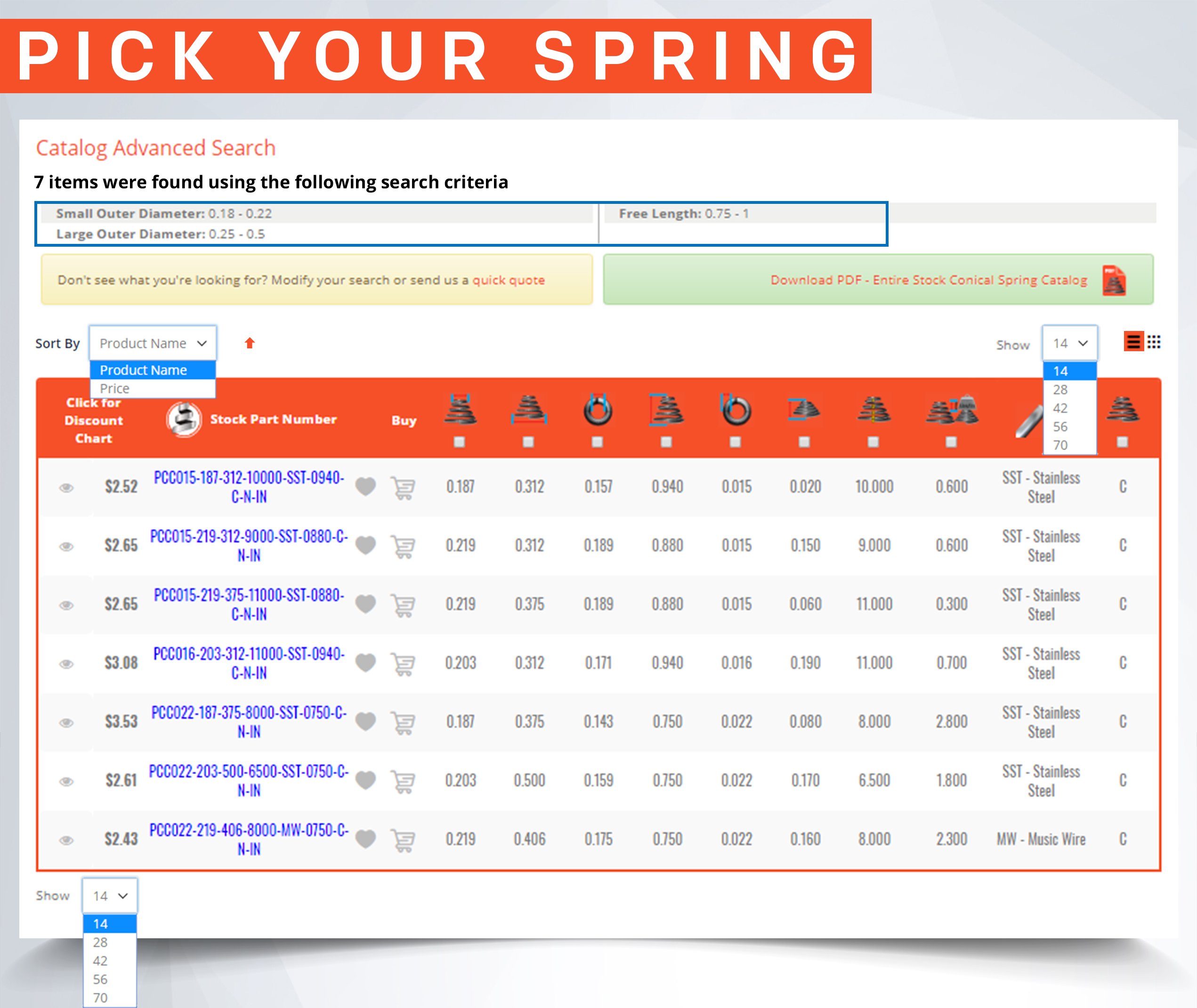

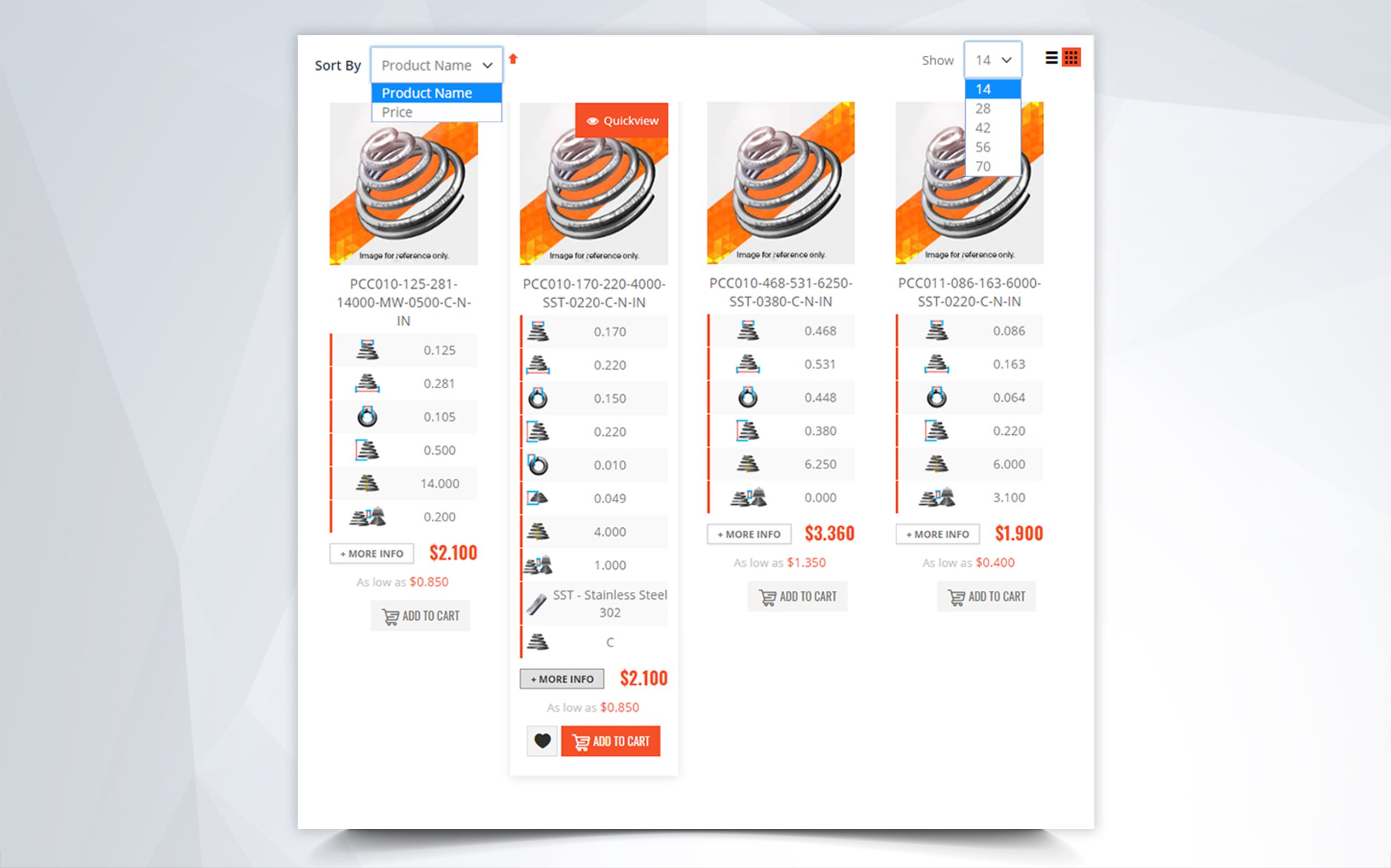

If you are looking for an open wound helical spring be sure to use our spring finder search tool by clicking here: Spring Finder

Just input the dimensions you need and immediately get a list of all the compression springs we have in stock that meet your needs.