Top Reasons 4 Reasons Springs Fail

Springs are made to be practical and durable. The problem is that many times they are placed under unfavorable conditions or not properly cared for, this causes them to fail and can lead to malfunction. There are different conditions and situations that can lead to spring failure. Being aware of what situations can affect your spring will help you prevent malfunction.

Top 4 Reasons Springs Fail

1. Excessive load.

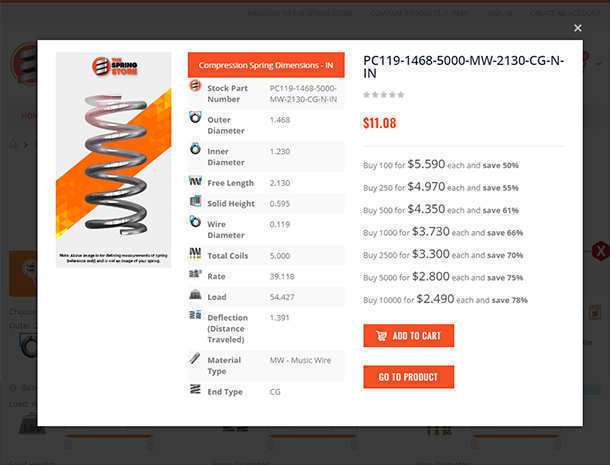

It is very important that you consider what the max. load for your spring is. Always stay within the recommended load. Placing an excessively heavy load is one of the most common reasons why springs fail. Every spring has a limited range and weight it can support be aware of what this is for each specific spring so you can respect those ranges.

2.The Environment.

The environment surrounding the spring is also a very important factor. The humidity, location and temperature around the spring play a role in the spring’s life span. Stainless steel can withstand certain humidity and exposure to water but music wire cannot. Placing a music wire spring in a corrosive environment will damage the spring and cause it to fail. Besides that, music wire will only withstand a maximum temperature of 250ºF while other material types may withstand higher temperatures. Ensure that you buy the right material type for the type of environment that you spring will be placed in. For more information on material types selection click here.

3. An Excess in Friction.

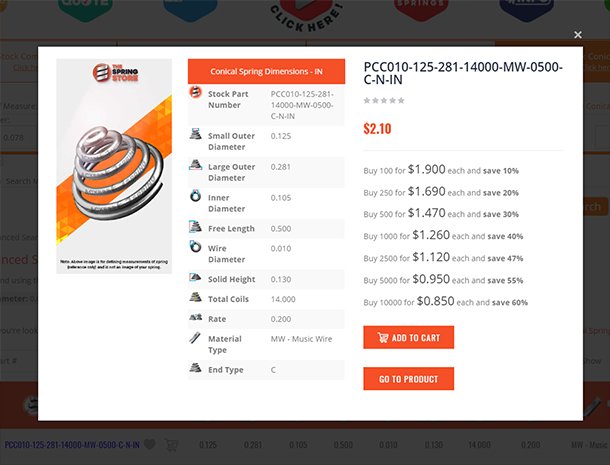

Springs can last a long time when they are not abused. However, if overworked, their life span will be shortened and might quickly fail. Placing a spring into a tube or into a rod without enough space can create constant friction between metals that can damage the spring. In many cases, lubrication helps but the spacing between metals is also important. Ensure that the dimensions of your spring are adequate for the space it will be placed in.

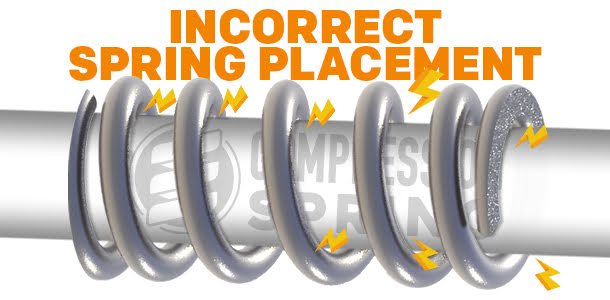

4. Inadequate Placement of the Spring.

Once you have the right spring, made of the correct material and have secured the proper spacing, make sure that the spring is placed correctly. Secure the spring into the rod or space where it will go. Ensure that it is adequately adjusted into the space and check to make sure it isn’t lose or buckling. To learn more about what buckling is and how this affects your spring CLICK HERE. Failure to properly place the spring can cause it to fail, and it may become a liability.

Selecting the right spring and taking the proper action steps will allow your spring to have a longer life span, and will ensure that your device stays in optimal working conditions. To start designing the right spring click here.

For assistance in ordering the right compression spring, call us today at: (951) 276-2777. Place your order now and ask for your free gift!