Stainless Steel Helical Springs

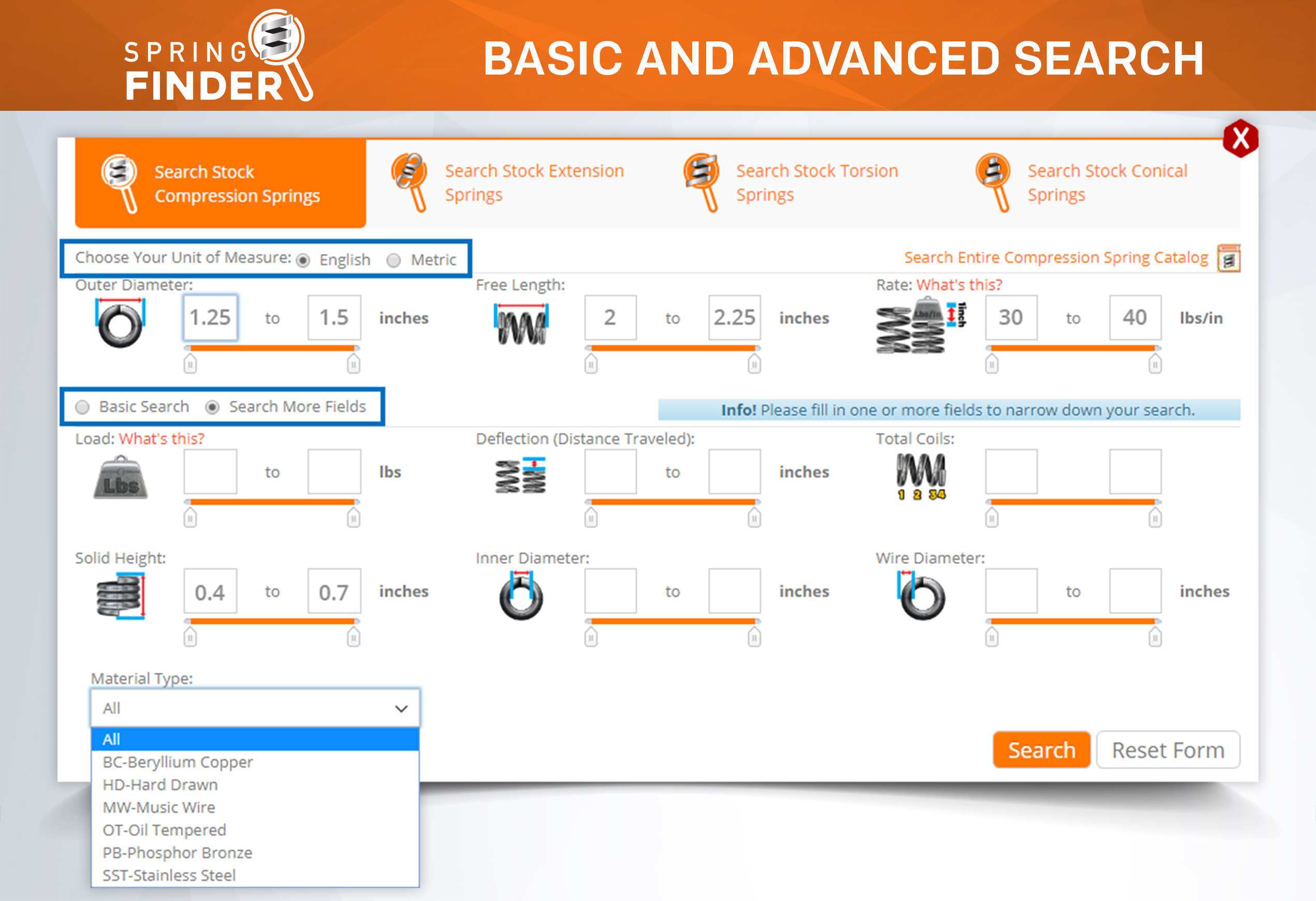

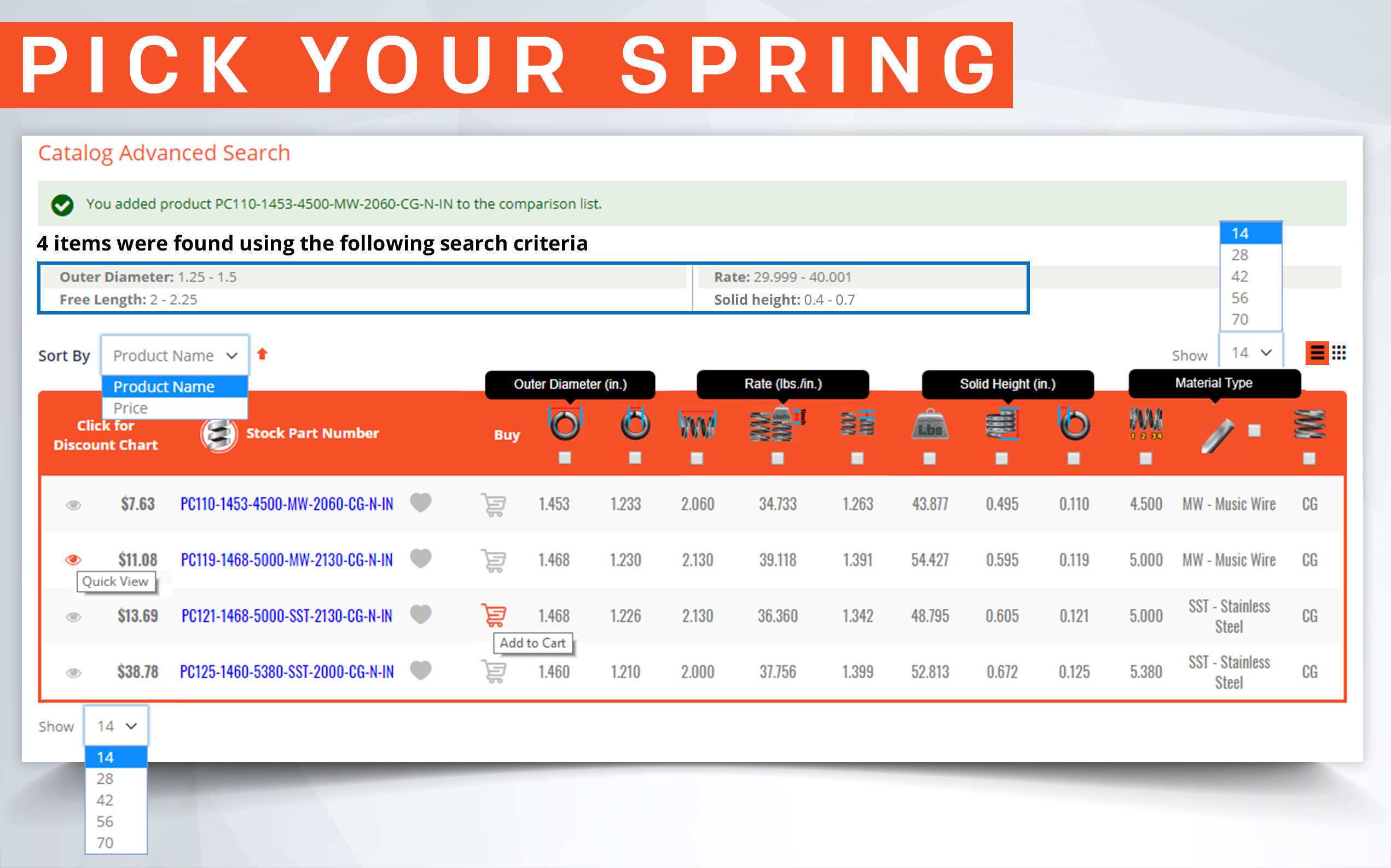

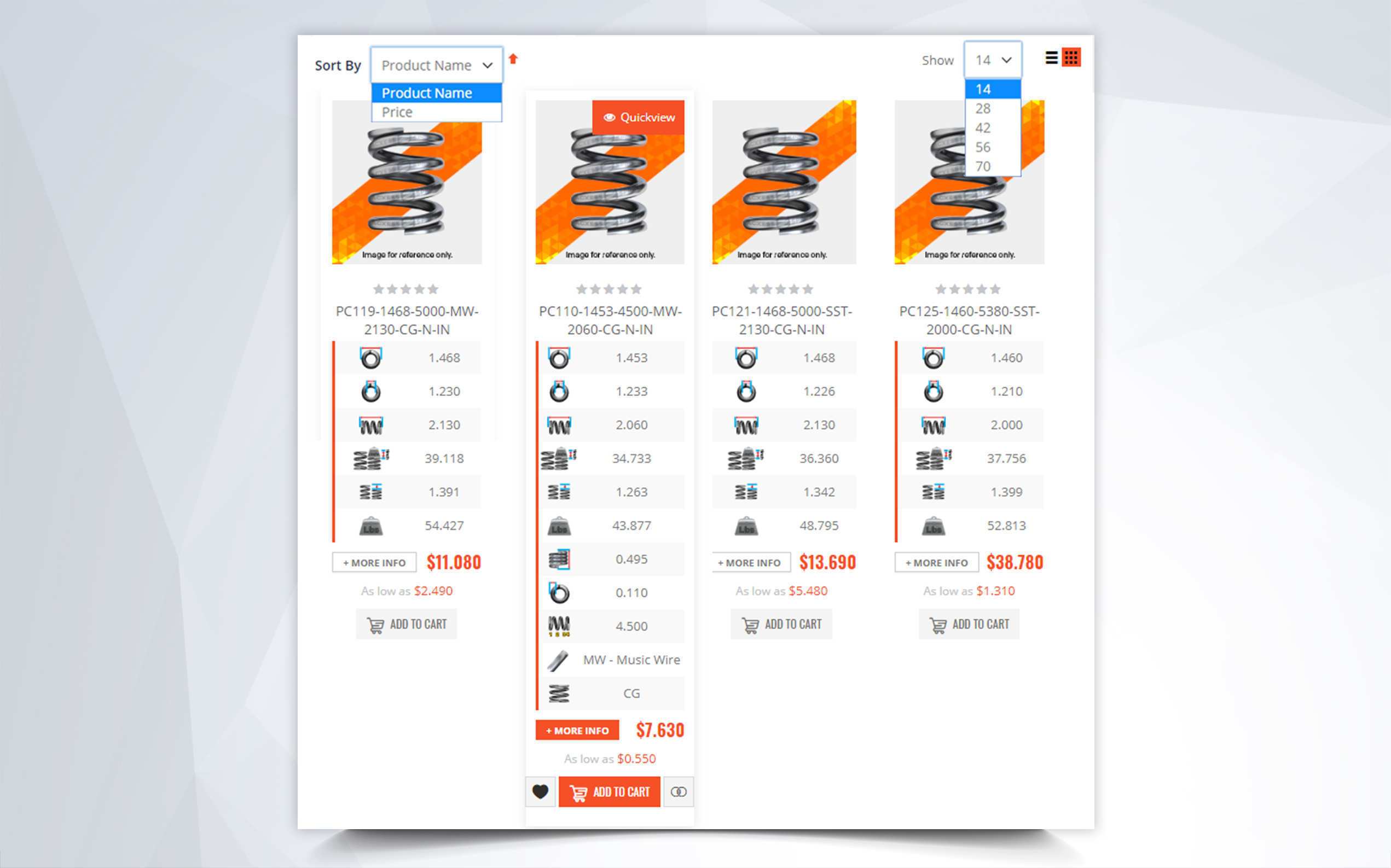

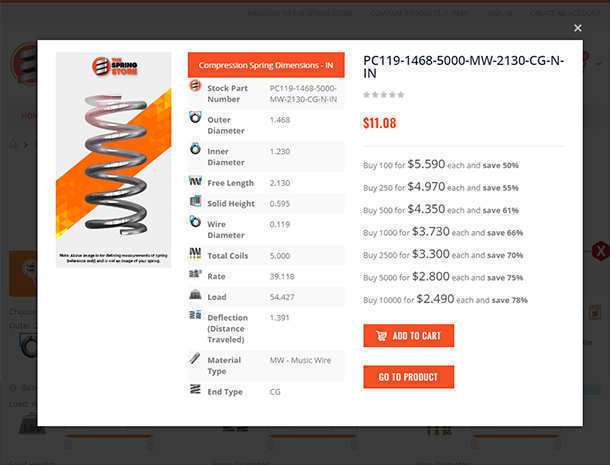

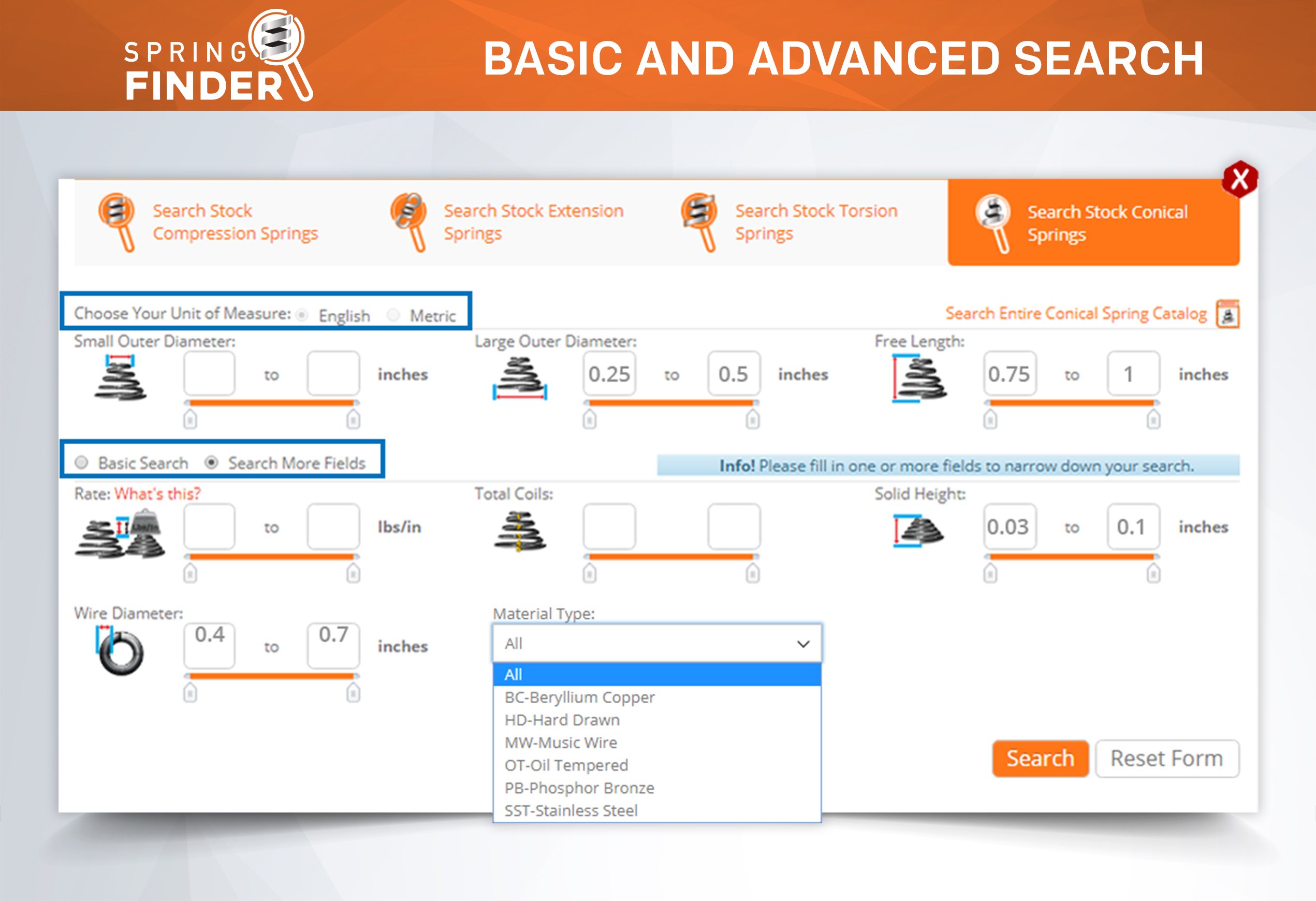

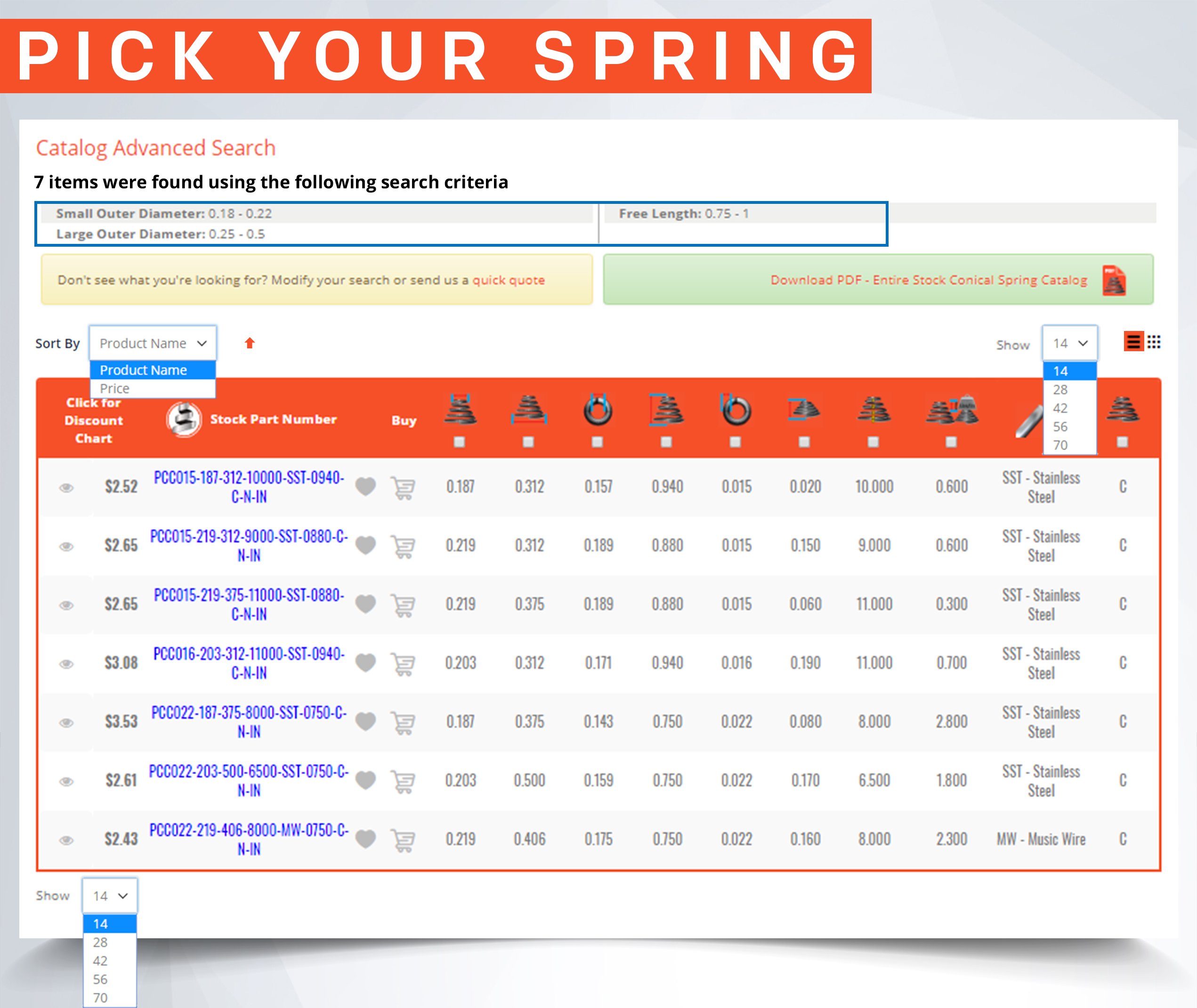

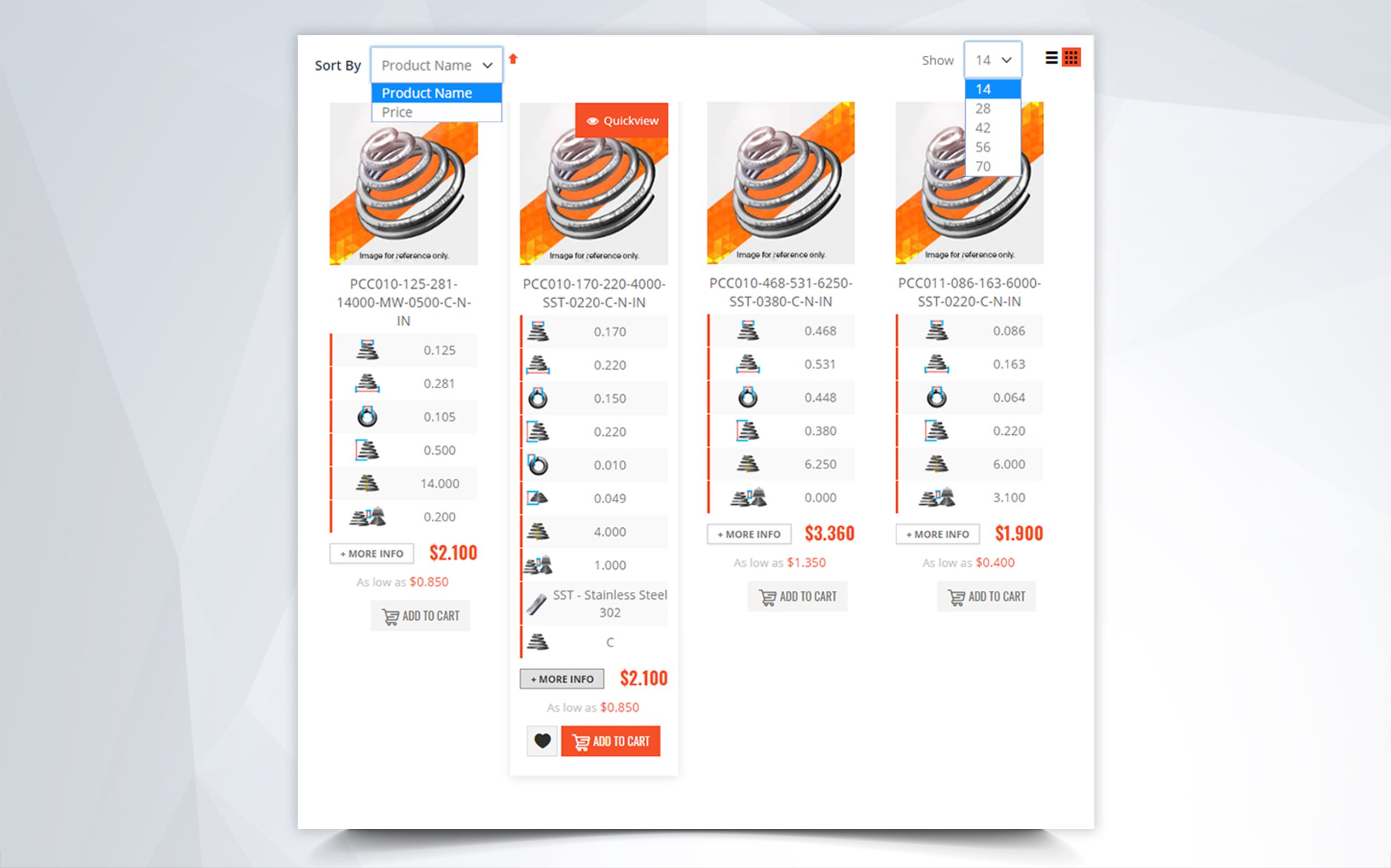

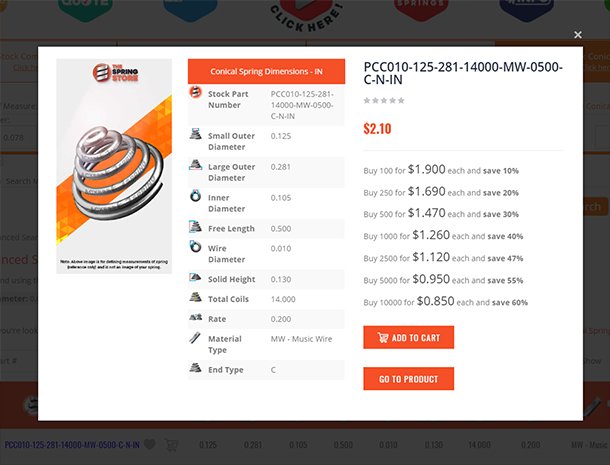

Find stock and custom helical springs made of stainless steel. In our stock compression spring catalog, you can select from over 6,500 stainless steel springs. We also carry stainless steel conical springs. Although the conical spring catalog is smaller it also offers a wide selection to meet your needs. Custom stainless steel springs can also be made to fit your application's requirements more specifically.

There are three types of stainless steel:

- Stainless Steel 302 ASTM A313

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 316 ASTM A316

Stainless Steel 302

This type of stainless steel is the most economical. It is made up of Chromium (Cr) and Nickel (Ni) so it is corrosion resistant and will not rust in humid environments. This material can bear temperatures as high as 550ºF (288ºC). It is used for general purpose, corrosion, and heat resistance.

| Material | AISI 302/304 ASTM A 313 |

| Nominal Analysis | Cr-17.0-19.0% Ni-8.0-10.0% |

| Minimum Tensile Strength | 125-325 |

| Modulus of Elasticy E psi x 10 ³ | 28 |

| Design Stress % Minimum Tensile | 30-40 |

| Modulus in Torsion G psi x 106 | 10 |

| Maximum Temp.°:F | 550º |

| Maximum Temp. °C | 288º |

| Rockwell Hardness | C35-45 |

| Method of Manufacture | Cold drawn. |

| Chief Uses | General purpose,corrosion and heat resistant. |

| Special Propeterties | Magnetic in spring temper. |

Stainless Steel 17-7

This material type is a bit more expensive than 302 but it does give you more as well. It is made from Chromium (Cr) and Nickel (Ni) like stainless 302 but 17-7 has aluminum as well. These material properties allow this wire type to have more corrosion resistance.

| Material | 17-7 PH ASTM A 313 (631) |

| Nominal Analysis | Cr-16.0-18.0% Ni-6.5-7.5% Al-.75-1.5% |

| Minimum Tensile Strength | Cond CH 235-335 |

| Modulus of Elasticy E psi x 10 ³ | 29.5 |

| Design Stress % Minimum Tensile | 45 |

| Modulus in Torsion G psi x 106 | 11 |

| Maximum Temp.°:F | 650º |

| Maximum Temp. °C | 343º |

| Rockwell Hardness | C38-57 |

| Method of Manufacture | Cold drawn & precipitation hardened after fabrication. |

| Chief Uses | High strengh and general purpose corrosion resistance. |

| Special Propeterties | Slightly magnetic in spring temper. |

Stainless Steel 316

This particular stainless steel type has similar pricing to 17-7 but it is more extravagant and there is a very limited supply which can boost up the prices from time to time. Stainless 316 is made from Chromium (Co), Nickel (Ni), and Molybdenum (Mo). Thanks to these properties, This material can resist temperatures as high as 650ºF (343ºC) and is 90% non-magnetic.

| Material | AISI 316 ASTM A 313 (631) |

| Nominal Analysis | Cr-16.0-18.0% Ni-10.0-14.0% Mo-2.0-3.0% |

| Minimum Tensile Strength | 110-245 |

| Modulus of Elasticy E psi x 10 ³ | 28 |

| Design Stress % Minimum Tensile | 40 |

| Modulus in Torsion G psi x 106 | 10 |

| Maximum Temp.°:F | 550º |

| Maximum Temp. °C | 288º |

| Rockwell Hardness | C35-45 |

| Method of Manufacture | Cold drawn. |

| Chief Uses | Heat resistant and better corrosion resistance than 302. |

| Special Propeterties | 90% Non-Magnetic in spring temper. |