Spring Compression Formula

Definition - The mathematical rule of a compression spring’s travel calculation expressed in symbols.

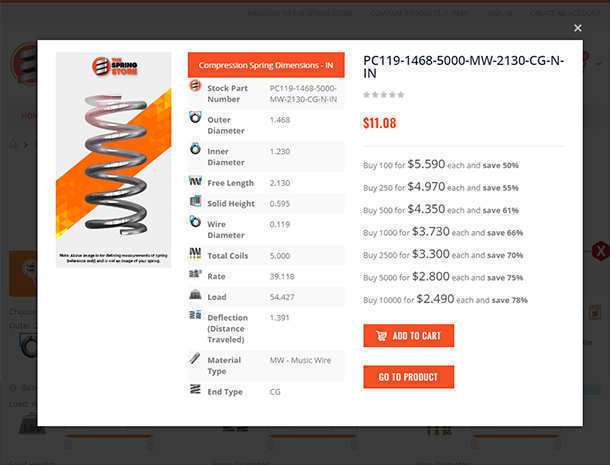

When working on a compression spring design there are a several key factors. The first factors are the physical dimensions ensuring your spring appropriately fits into your application. Your spring’s working loads are another elemental component that you have to consider.

The working loads determine the force you will need to place on your spring in order for it to travel down to a determined loaded height or vice versa. It can also be the loaded height your spring needs to travel under a specific load.

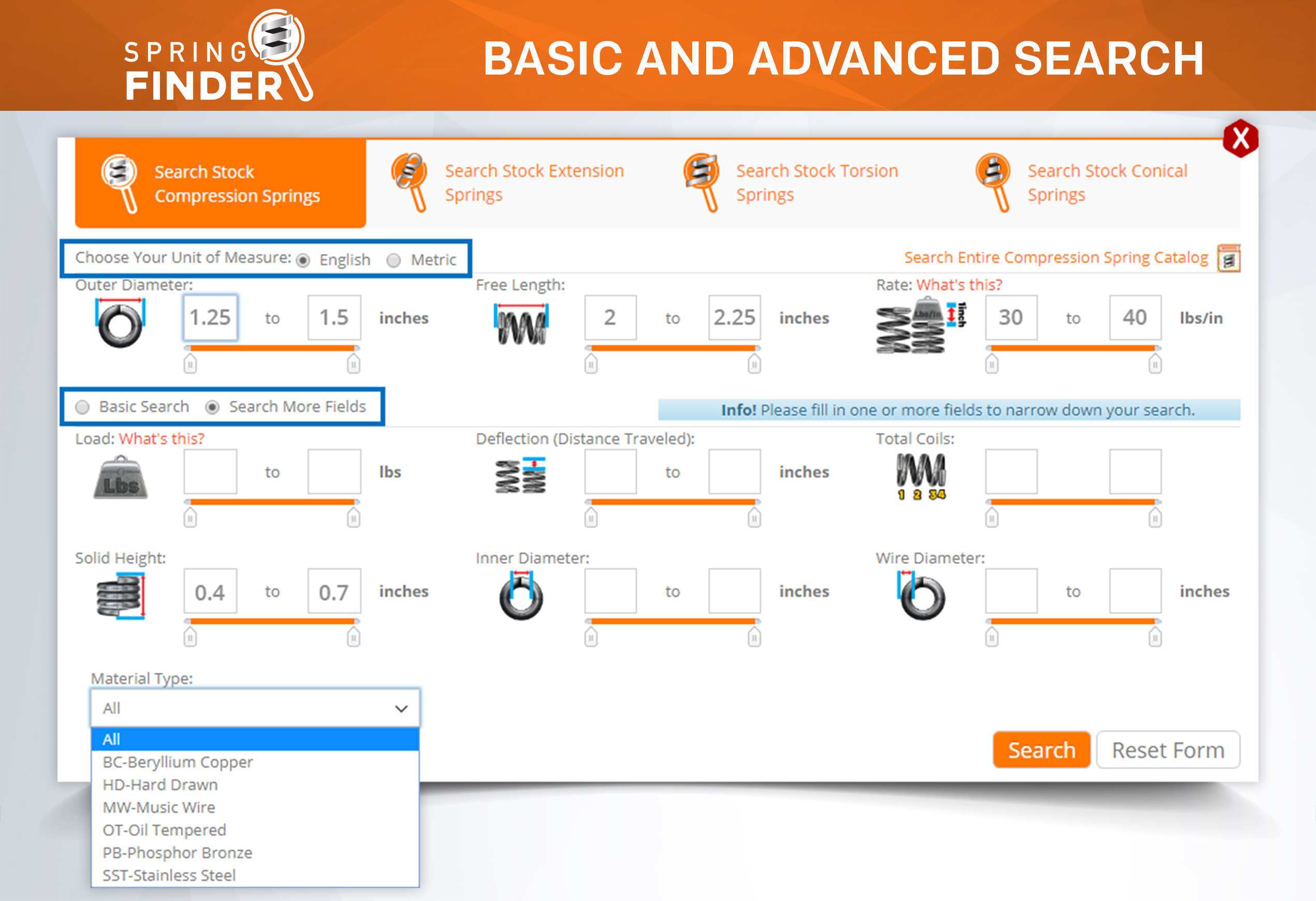

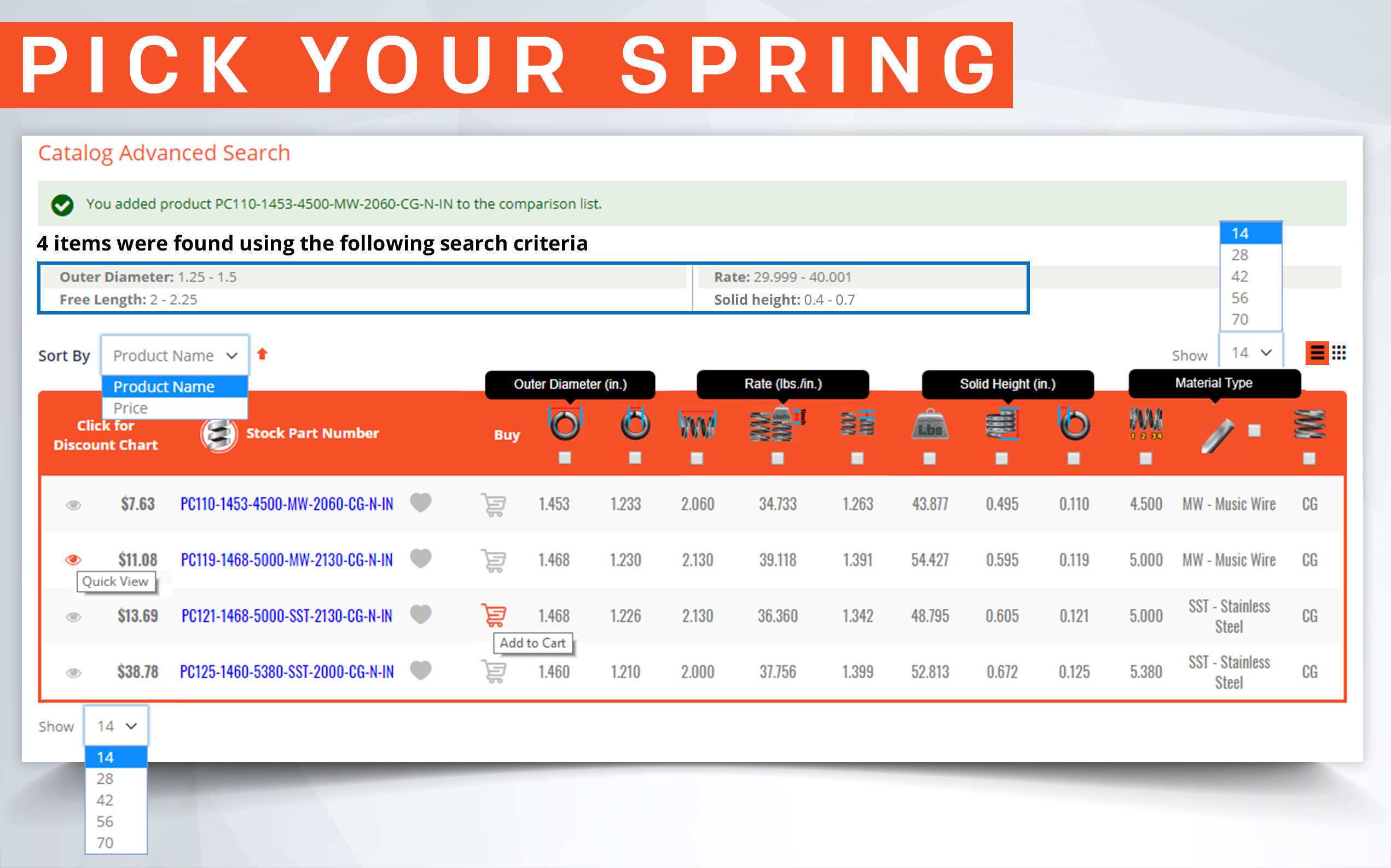

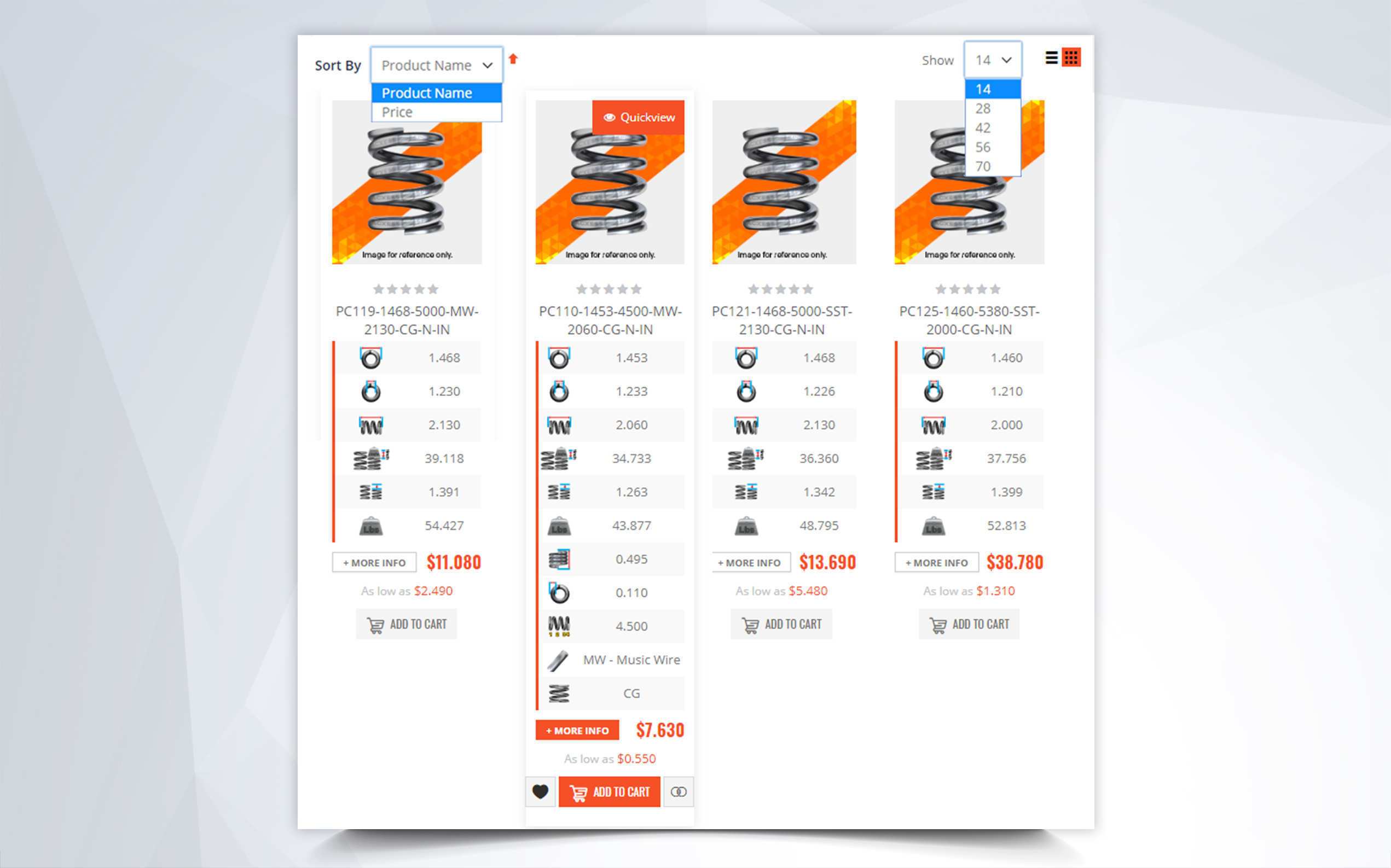

Whichever the case, we want to provide you with the spring compression formulas to calculate the travel. If you don`t want to learn how to calculate them yourself, no problem! Just use our spring calculator, Spring Creator, to calculate them automatically.

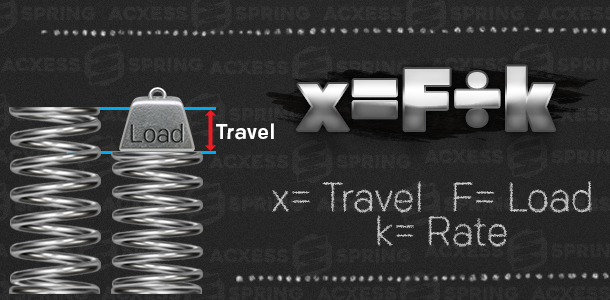

For compression springs you need two values: load and spring rate. Spring rate is the master of your working load calculations. Whether you are calculating load or travel, spring rate will always be required. The formula to calculate spring travel is the load divided by the spring rate. The result of this is the amount of travel your spring will achieve under the load placed.

Spring Compression Formula

x = F ÷ k- x - Travel

- F - Load

- k - Rate

Based on these calculations you will know if your spring has the adequate force and elasticity, or if it needs to be either stronger or weaker. The force chart to the right explains the adjustments you can make to your spring design to increase or reduce its force and elasticity. The stronger and stiffer the spring, the more stress it is being put through, thus giving you less travel.

To make your spring lighter and achieve more spring compression, you must either make the outer diameter larger, make the wire diameter smaller, add coils, or (if your design allows it) make the free length shorter. By making the free length shorter, it will take your spring less travel to reach the desired loaded height thus requiring less force.

To make your spring stronger, you must do the exact opposite: increase the wire diameter, decrease the outer diameter, subtract coils, or increase the free length (if your design allows it). By making the free length longer, you allow it to withstand a higher load since it will take your spring more travel to reach the desired loaded height.

| More Compression | Less Compression |

|---|---|

| – Wire Diameter | + Wire Diameter |

| + Outer Diameter | – Outer Diameter |

| + Coils | – Coils |

| + Free Length | – Free Length |

To know whether your spring design will allow you to increase the free length and still be able to reach your required loaded height, click here for information on maximum spring compression.