Hourglass Springs

Hourglass springs also known as concave springs are called that due to their shape. This type of compression spring has an hourglass or barbell shape. A concave spring reduces space, prevents buckling, There are more options as there are a wide variety of shaped configurations to choose from to fit in any design.

Among the many benefits of hourglass springs is that their concave design reduces space and gives more stability. In fact if you think about it, the shape of a concave or hourglass spring is that of one inverted conical spring and one regular spring placed on top of each other. A concave spring is wider in the end coils than the center coils, so the pressure is distributed differently, allowing for better stability. This makes them ideal for applications where stability is a must but a spring is unable to be placed on a rod or in a hole.

Concave springs are also beautiful forms of art. Their shape can be eye-captivating and a truly visually enhancing piece for any device or application. This is an added bonus to these types of springs, not to mention that since they are specialty springs they can also be quoted for additional visual enhancements such as plating. A finish such as nickel plating can create an even more appealing look for both the spring and product.

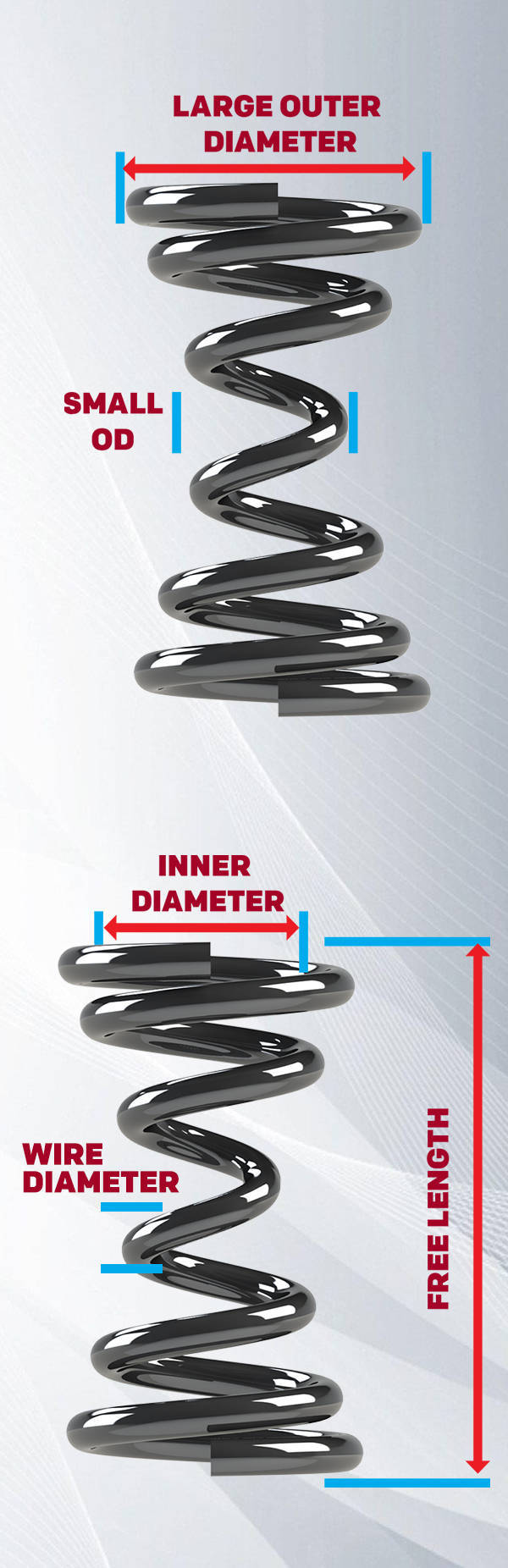

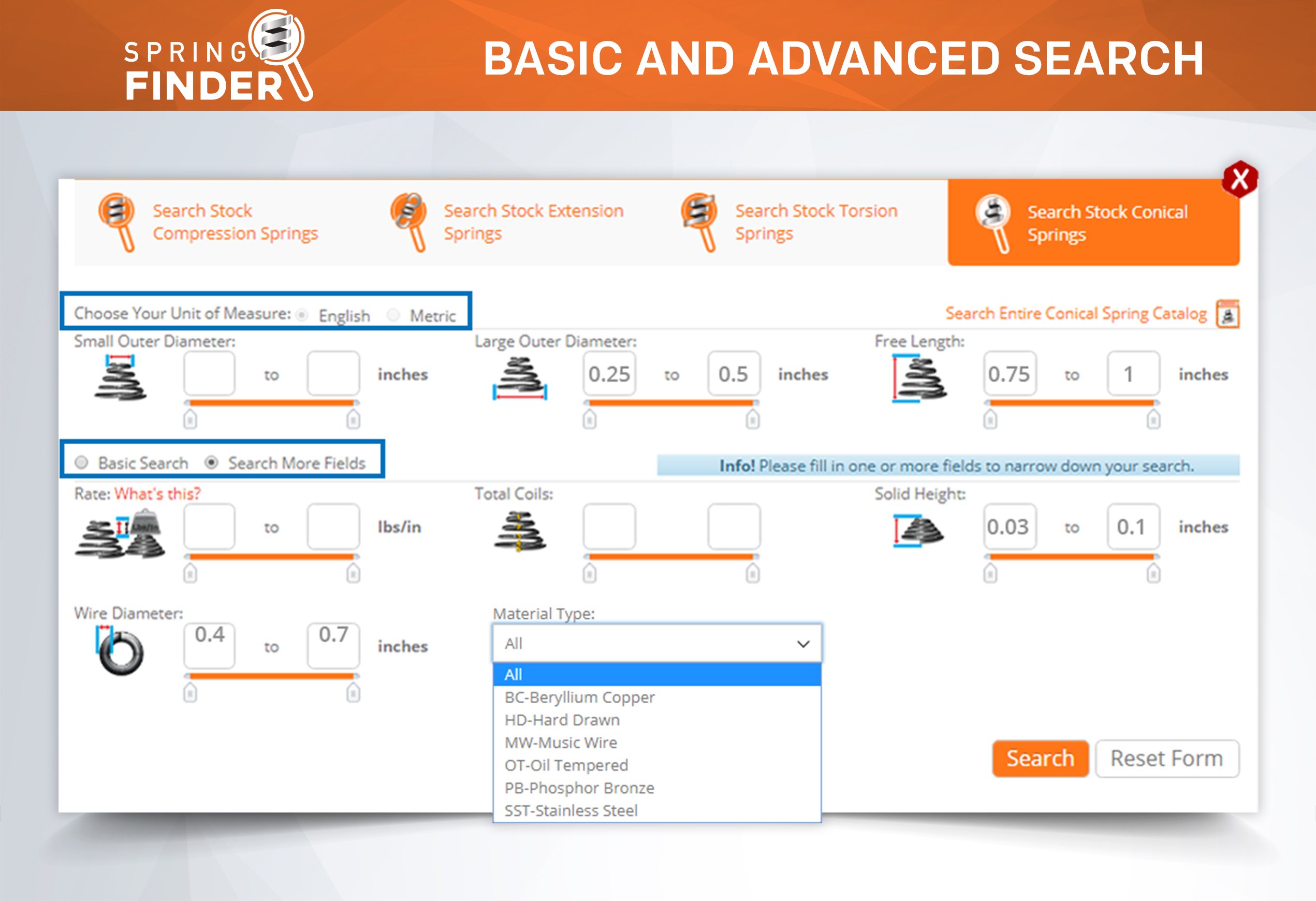

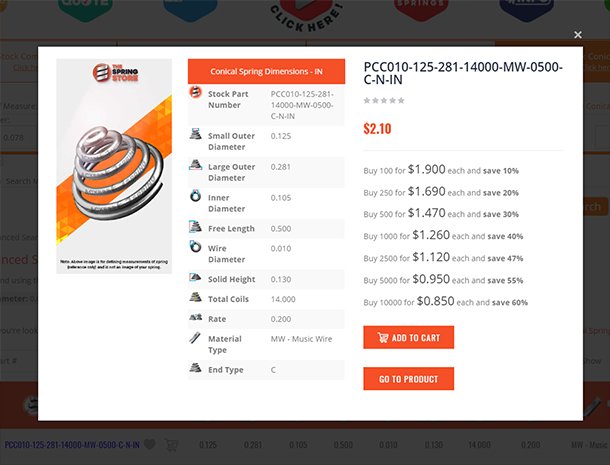

One more thing to keep in mind regarding hourglass springs is that due to the nature of their shape these will have a few different dimensions in comparison to those of a regular compression spring . Below is a list of some of the specs and dimensions you need to consider when thinking about an hourglass spring design.

Wire Diameter (WD)

The thickness of the round wire which the compression spring is made of.

Large Outer Diameter

The thickness of the largest coil in the barrel compression spring’s body.

Small Outer Diameter

The thickness of the smallest coil in the barrel coil spring’s body.

Inner Diameter (ID)

The width of the inside of the smallest coil. Calculate by subtracting two wire diameters from the small outer diameter.

Mean Diameter (MD)

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Free Length (FL)

The free, unloaded length of a barrel spring.

Total Coils (T/C)

The total amount of coils including open and closed coils.

Active Coils (A/C)

The open/active coils in your barrel spring. You may calculate the active coils by subtracting the closed coils from the total coils.

Solid Height (LH)

The length/height of your spring when it is fully compressed and all of the coils are touching.

Spring Pitch (P)

The distance between your spring’s coils.

Rise Angle of Coils

Because, there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the angle of the coil is raised.