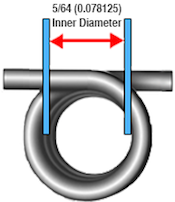

5/64" (0.078125) Inch Inner Diameter Standard Torsion Springs

Definition of 5/64" Inner Diameter Torsion Springs:

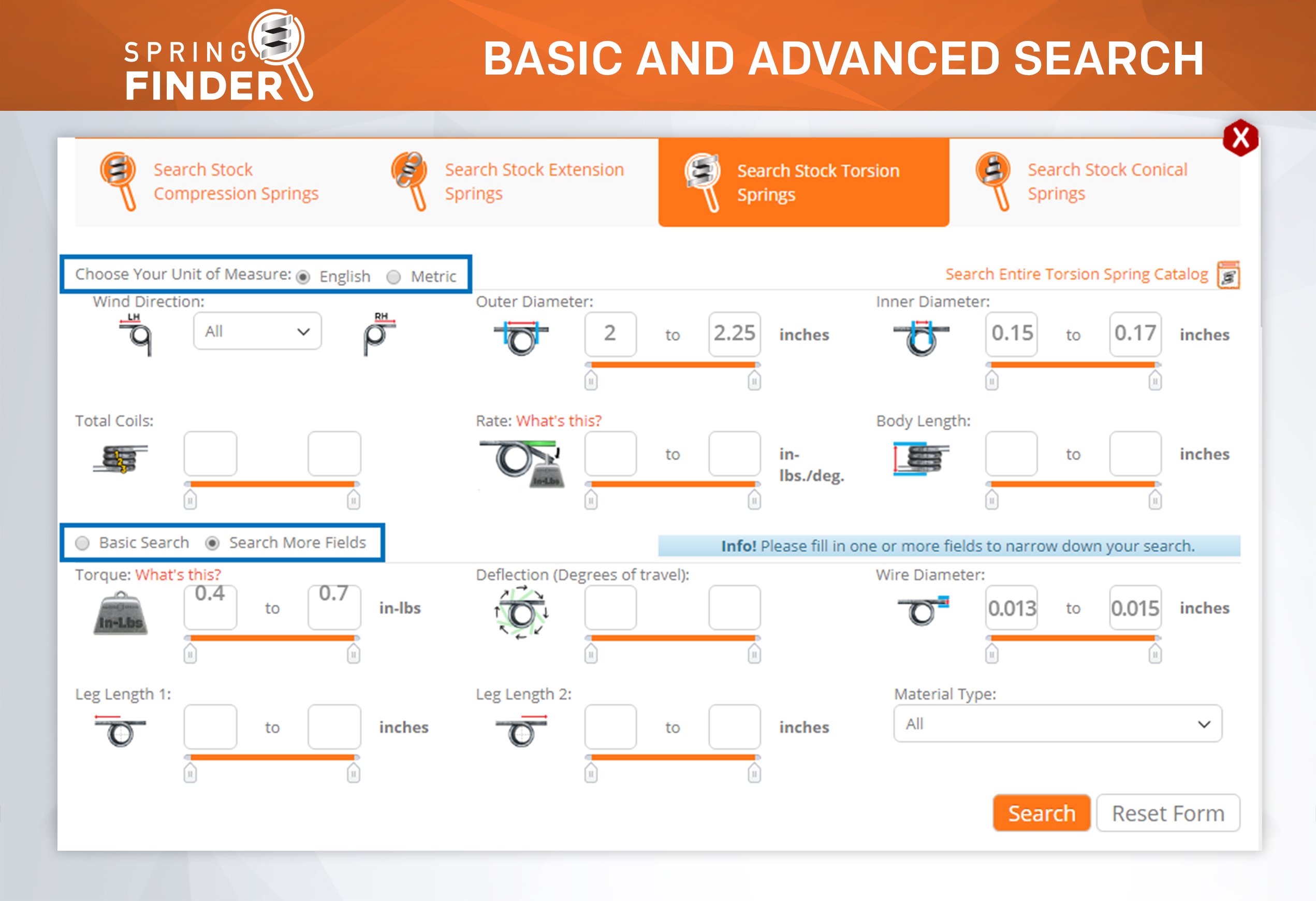

A 5/64" (five sixty-fourths of an inch) inner diameter torsion spring has an inner diameter of 0.078125 inches and may fit over a mandrel or shaft diameter of approximately 1/16” (one sixteenth of an inch). You will find them in standard torsion spring catalogs where you may buy ready-made springs.

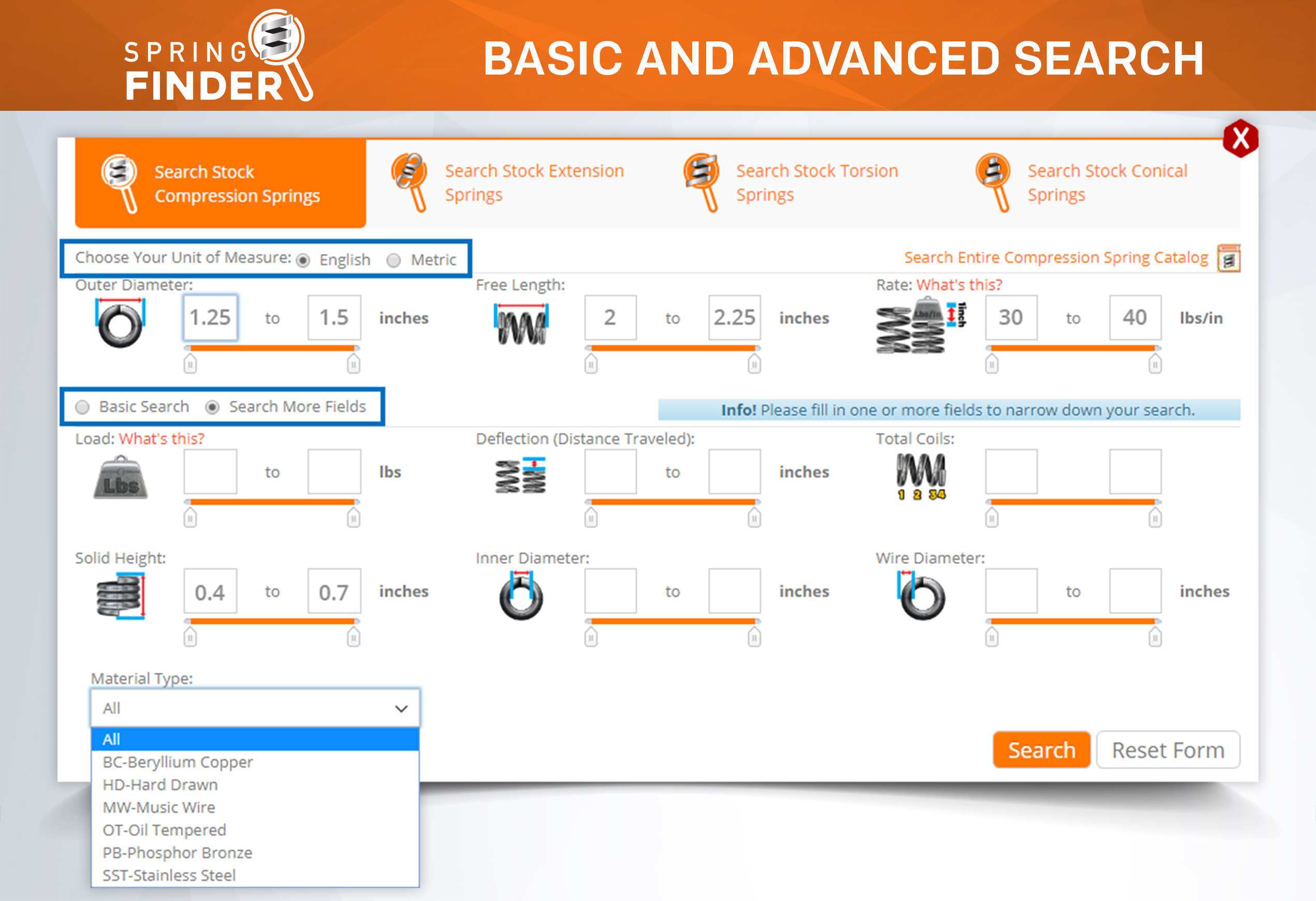

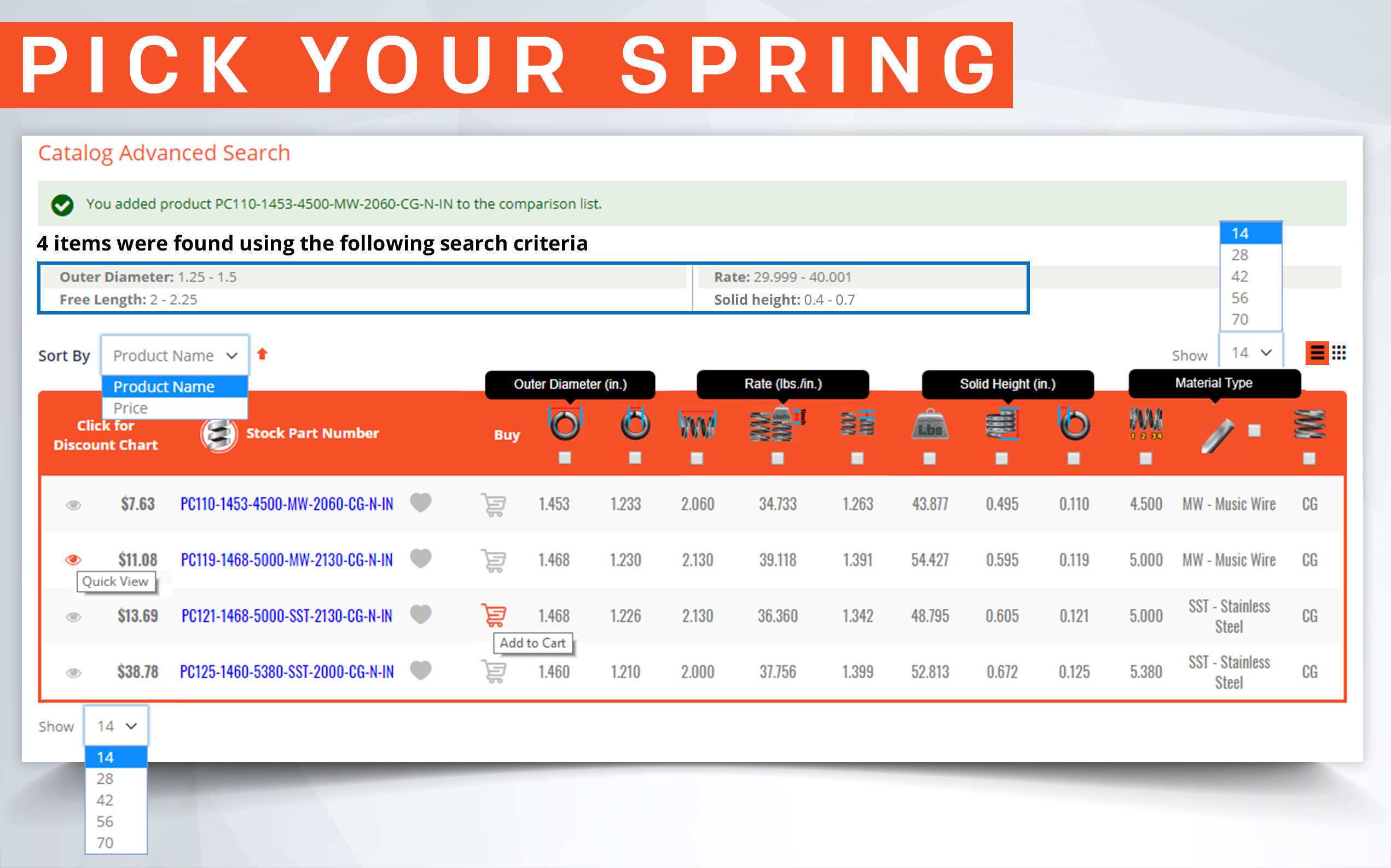

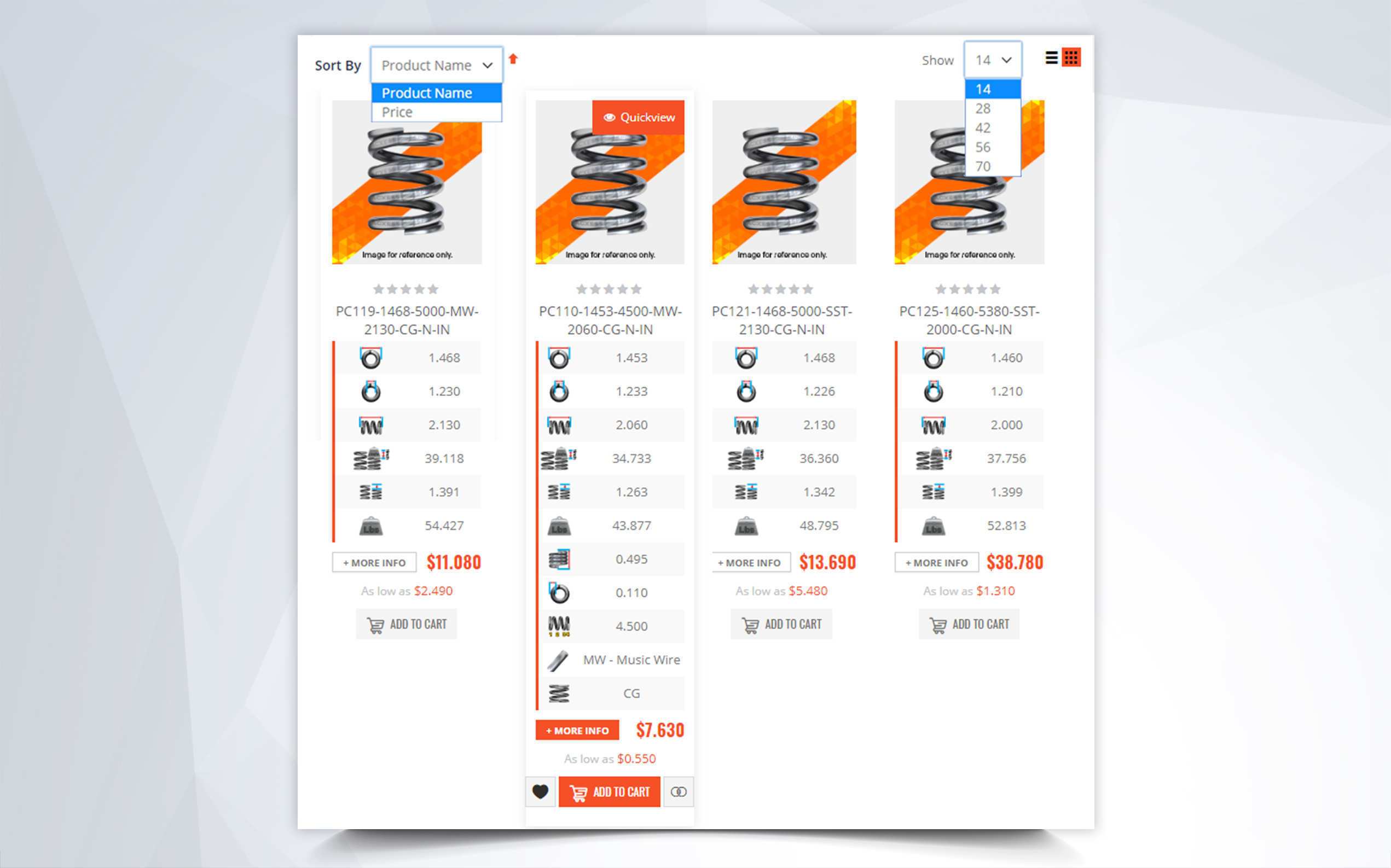

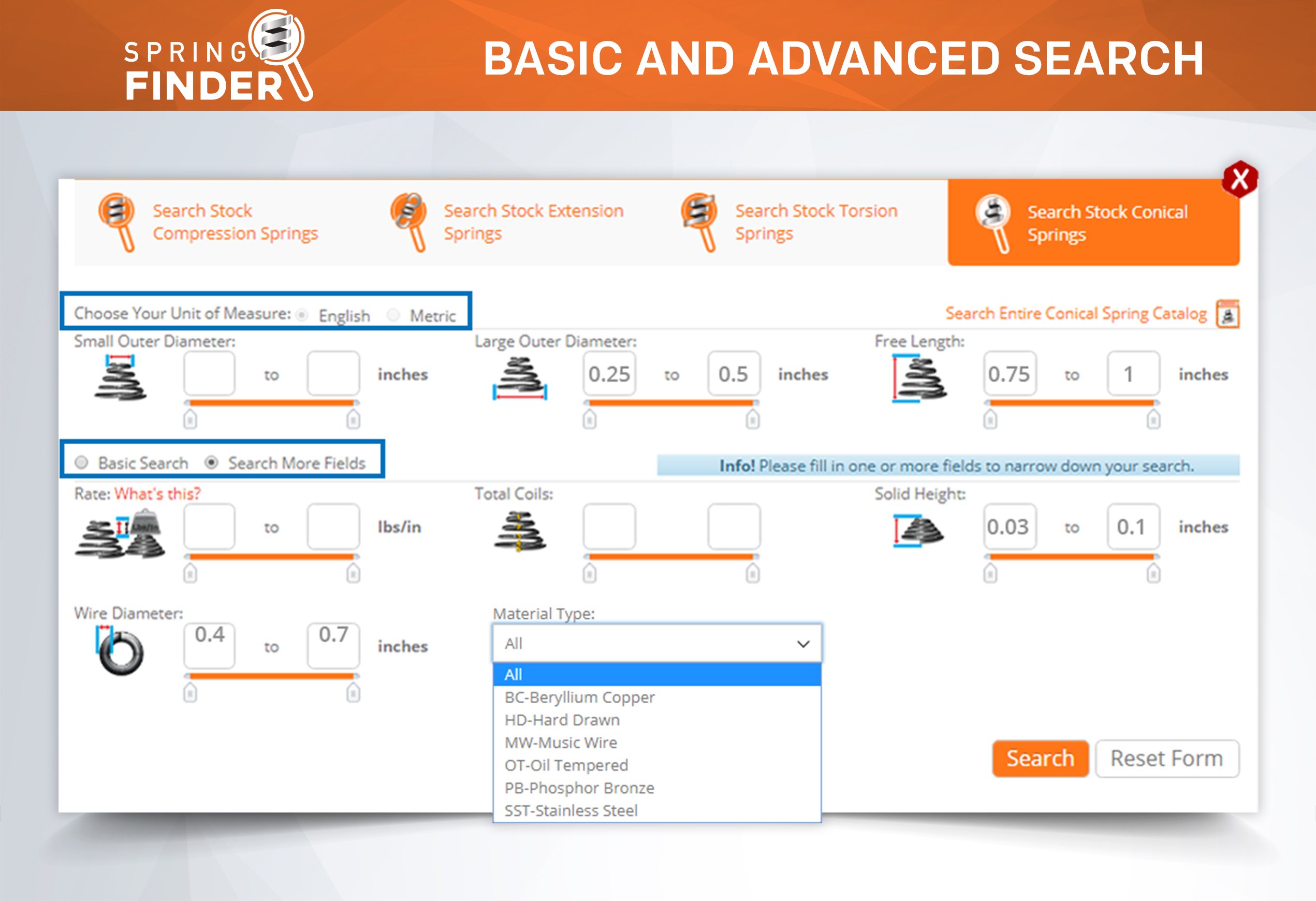

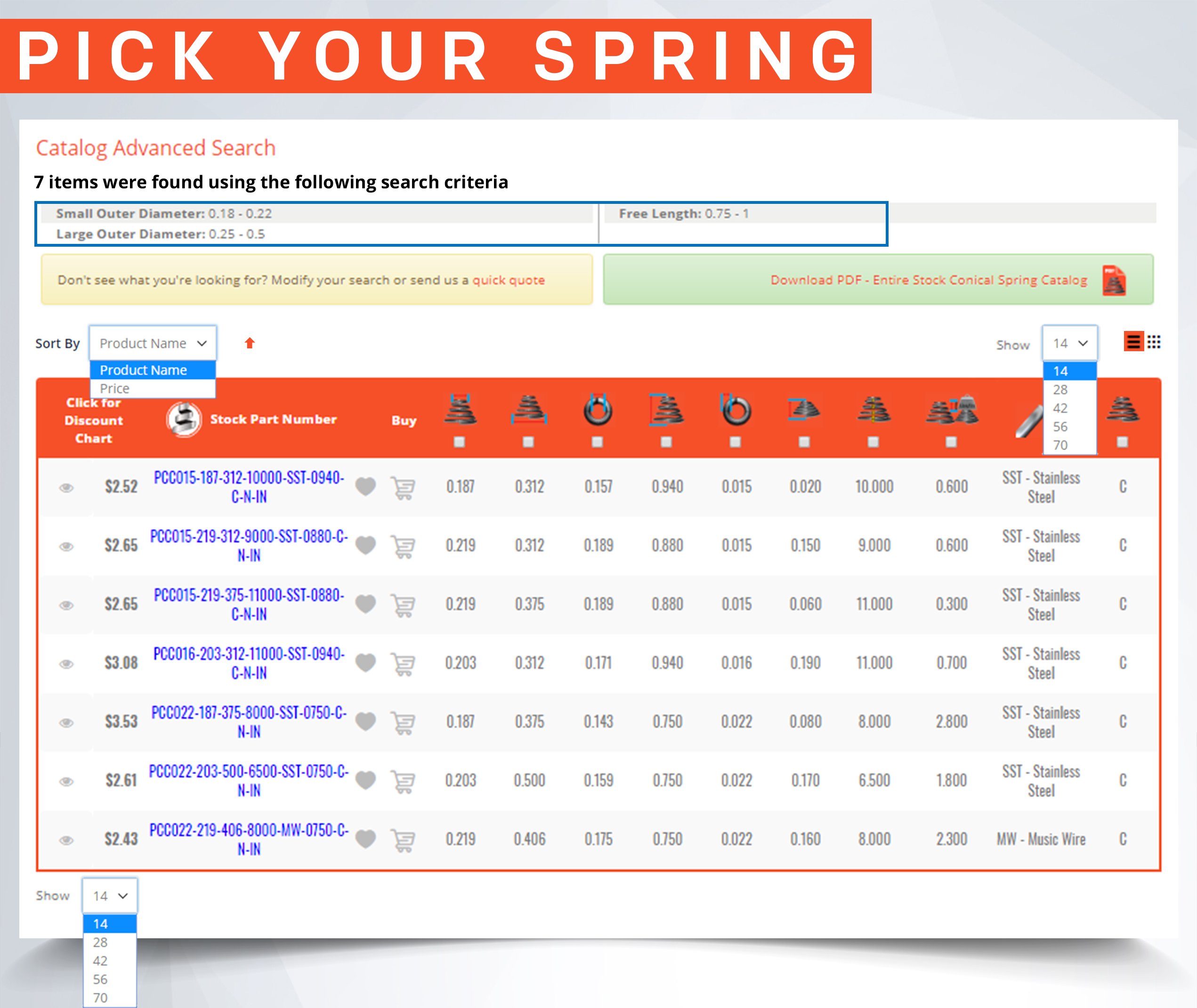

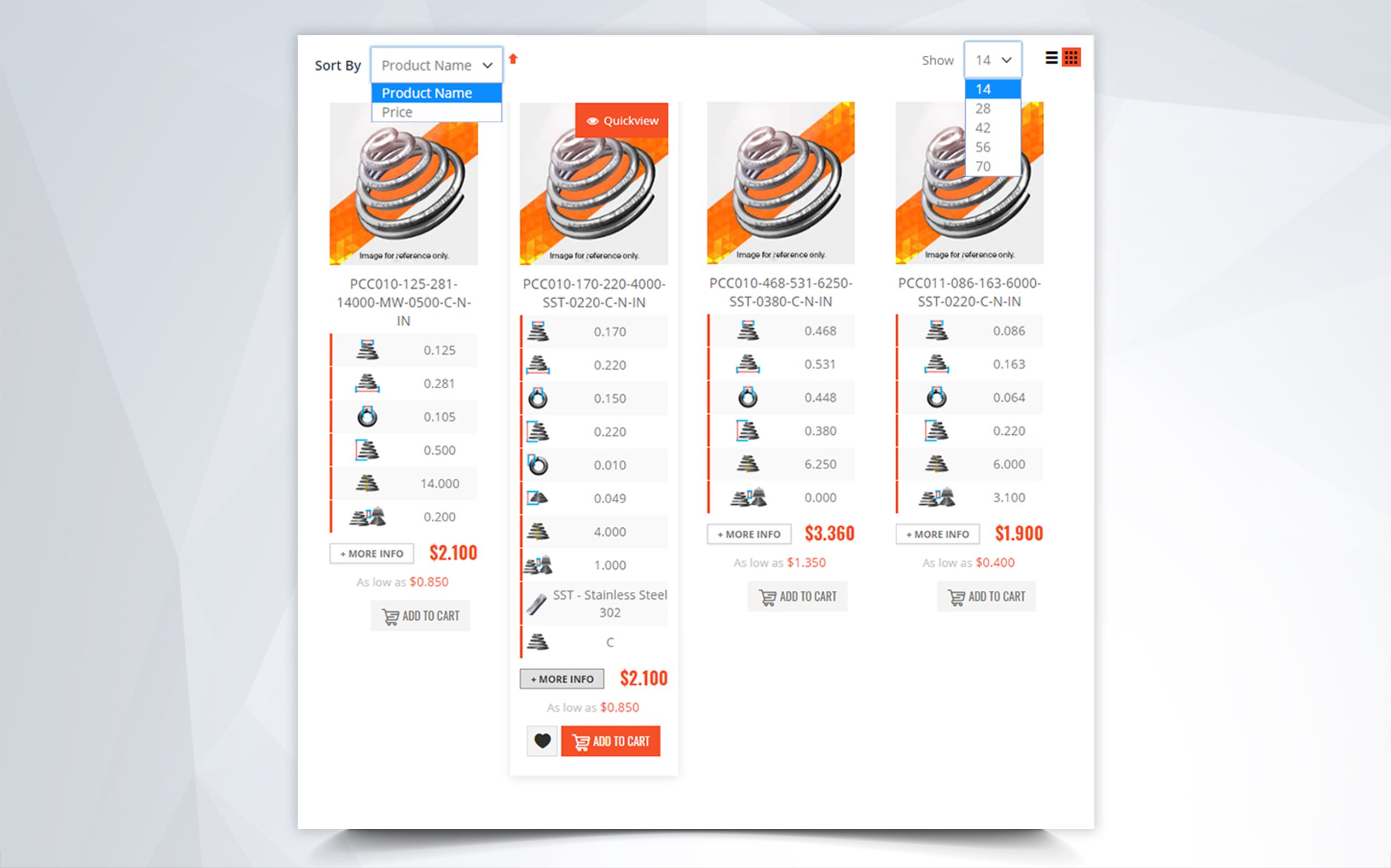

The Spring Store by Acxess Spring provides you with an extensive stock torsion spring catalog which you may search through by using our standard torsion spring finder.

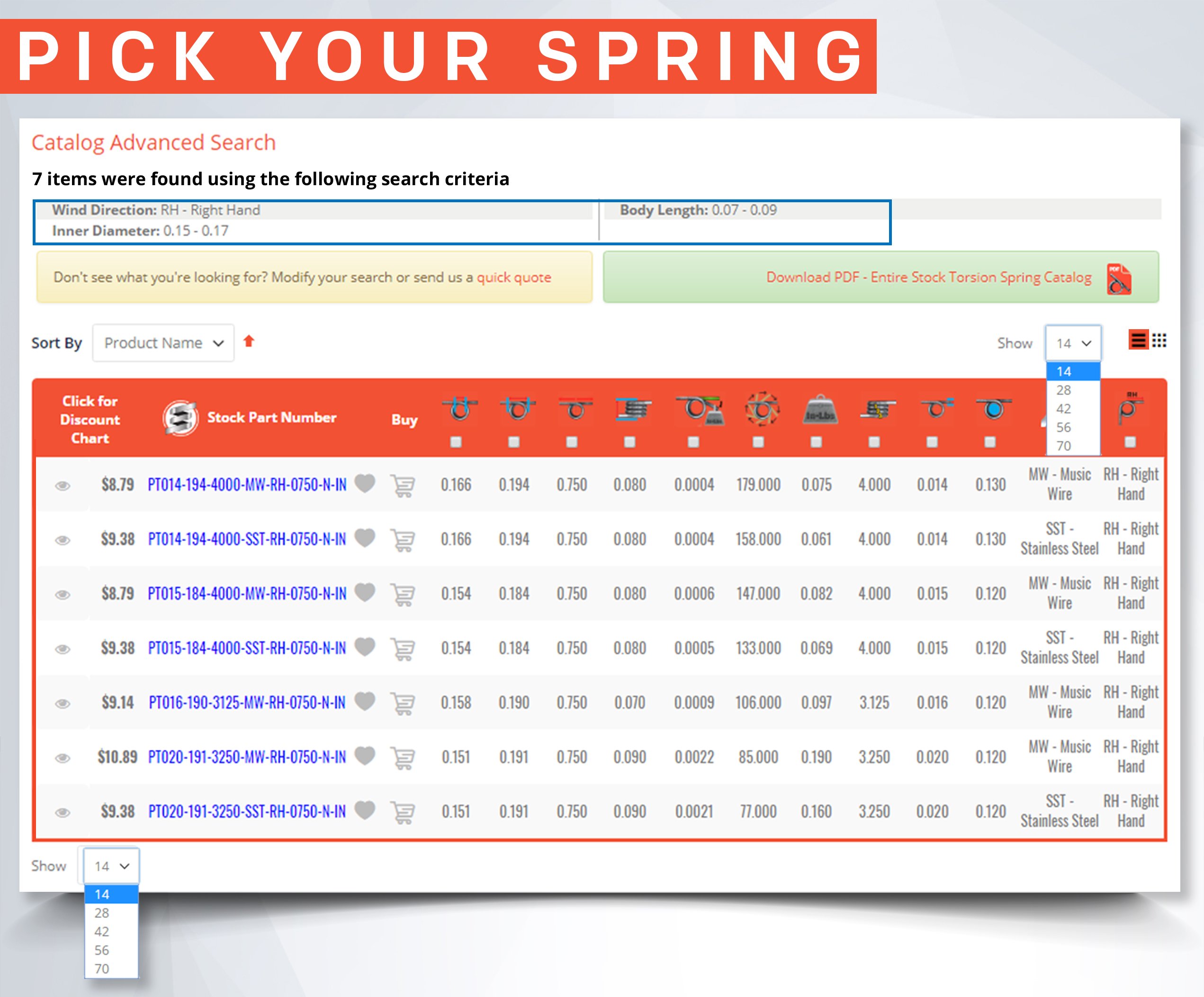

| Select. | TSS Part# | Inner Diameter by Fractions | Inner Diameter (in.) Decimals | Outer Diameter by Fractions | Outer Diameter (in.) Decimals | Leg Lengths (in.) | Body Length (in.) | Rate (in.-lbs./Deg.) | Sugg. Max. Defl. (deg.) | Sugg. Max. Load (in.-lbs.) | Total Coils | Wire Dia. (in.) | Sugg. Madrel Size in Fract. | Sugg. Mandrel Size (in.) | Material Type | Finish | Wind Direct. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

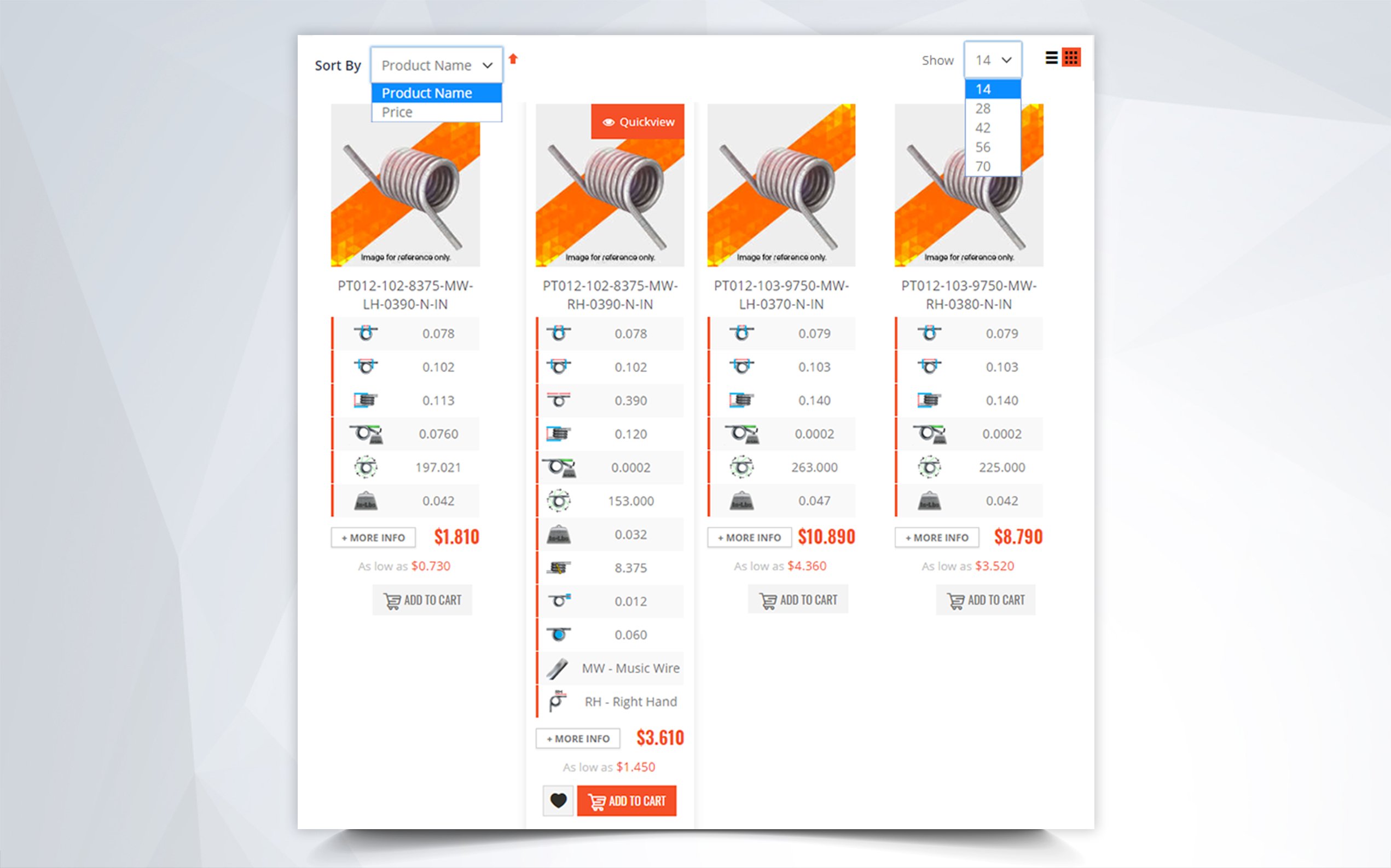

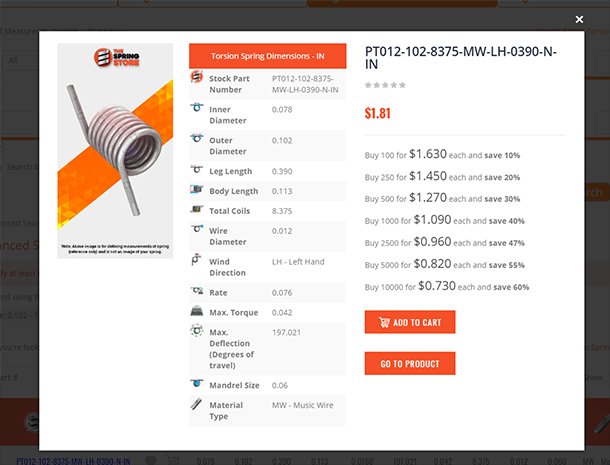

| PT012-102-8.375-MW-RH-0.390-N-IN | 5/64 = | 0.078 | 7/64 = | 0.102 | 0.390 | 0.120 | 0.00021 | 153 | 0.032 | 8.375 | 0.012 | 1/16 = | 0.060 | MW-Music Wire | N | Right Hand | |

| PT012-103-9.750-MW-LH-0.370-N-IN | 5/64 = | 0.079 | 7/64 = | 0.103 | 0.370 | 0.140 | 0.00018 | 263 | 0.047 | 9.750 | 0.012 | 1/16 = | 0.060 | MW-Music Wire | N | Left Hand | |

| PT012-103-9.750-MW-RH-0.380-N-IN | 5/64 = | 0.079 | 7/64 = | 0.103 | 0.380 | 0.140 | 0.00019 | 225 | 0.042 | 9.750 | 0.012 | 1/16 = | 0.060 | MW-Music Wire | N | Right Hand | |

| PT012-103-9.750-SST-LH-0.380-N-IN | 5/64 = | 0.079 | 7/64 = | 0.103 | 0.380 | 0.140 | 0.00017 | 215 | 0.037 | 9.750 | 0.012 | 1/16 = | 0.060 | SST-Stainless Steel | N | Left Hand | |

| PT012-103-9.750-SST-RH-0.380-N-IN | 5/64 = | 0.079 | 7/64 = | 0.103 | 0.380 | 0.140 | 0.00017 | 215 | 0.037 | 9.750 | 0.012 | 1/16 = | 0.060 | SST-Stainless Steel | N | Right Hand | |

| PT012-105-3.250-MW-LH-0.380-N-IN | 5/64 = | 0.081 | 7/64 = | 0.105 | 0.380 | 0.060 | 0.00056 | 79 | 0.044 | 3.250 | 0.012 | 1/16 = | 0.060 | MW-Music Wire | N | Left Hand | |

| PT012-105-3.250-MW-RH-0.380-N-IN | 5/64 = | 0.081 | 7/64 = | 0.105 | 0.380 | 0.060 | 0.00056 | 79 | 0.044 | 3.250 | 0.012 | 1/16 = | 0.060 | MW-Music Wire | N | Right Hand | |

| PT012-105-3.250-SST-LH-0.380-N-IN | 5/64 = | 0.081 | 7/64 = | 0.105 | 0.380 | 0.060 | 0.00052 | 72 | 0.037 | 3.250 | 0.012 | 1/16 = | 0.060 | SST-Stainless Steel | N | Left Hand | |

| PT012-105-3.250-SST-RH-0.380-N-IN | 5/64 = | 0.081 | 7/64 = | 0.105 | 0.380 | 0.060 | 0.00052 | 72 | 0.037 | 3.250 | 0.012 | 1/16 = | 0.060 | SST-Stainless Steel | N | Right Hand | |

| PT015-111-3.250-MW-LH-0.500-N-IN | 5/64 = | 0.081 | 7/64 = | 0.111 | 0.500 | 0.070 | 0.00111 | 70 | 0.078 | 3.250 | 0.015 | 1/16 = | 0.060 | MW-Music Wire | N | Left Hand | |

| PT015-111-3.250-MW-RH-0.500-N-IN | 5/64 = | 0.081 | 7/64 = | 0.111 | 0.500 | 0.070 | 0.00111 | 70 | 0.078 | 3.250 | 0.015 | 1/16 = | 0.060 | MW-Music Wire | N | Right Hand | |

| PT015-111-3.250-SST-LH-0.500-N-IN | 5/64 = | 0.081 | 7/64 = | 0.111 | 0.500 | 0.070 | 0.00104 | 64 | 0.067 | 3.250 | 0.015 | 1/16 = | 0.070 | SST-Stainless Steel | N | Left Hand | |

| PT015-111-3.250-SST-RH-0.500-N-IN | 5/64 = | 0.081 | 7/64 = | 0.111 | 0.500 | 0.070 | 0.00104 | 64 | 0.067 | 3.250 | 0.015 | 1/16 = | 0.070 | SST-Stainless Steel | N | Right Hand | |

| PT012-109-6.000-SST-LH-0.380-N-IN | 5/64 = | 0.085 | 7/64 = | 0.109 | 0.380 | 0.090 | 0.00026 | 143 | 0.037 | 6.000 | 0.012 | 1/16 = | 0.070 | SST-Stainless Steel | N | Left Hand |

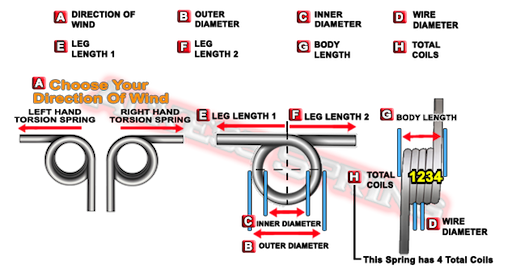

Your 5/64" (five sixty-fourths of an inch) torsion spring's measurements and dimensions have a lo to do with your standard torsion spring's force. For this reason, it is very important that the torsion spring's measurements are precise. Changing the wire diameter by even 0.001" can make a great difference on how strong your spring will be and how many degrees of travel you will be able to get out if it; especially with a spring as small as a 5/64" inner diameter torsion spring.

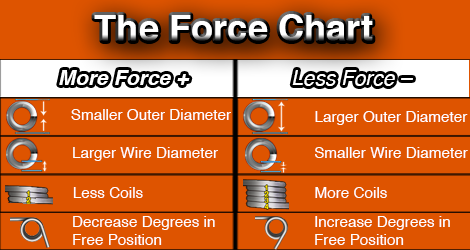

The 5/64" (five sixty fourths of an inch) inner diameter standard torsion springs provided here offer customers a wide variation of rate, load, and travel capacities. Every spring has its own amount of force due to the different physical dimensions; like wire diameter or total coils. The force chart to the right will explain what adjustments will make your spring stronger (more force) or weaker (less force).

For more force, you must either decrease your torsion spring's outer diameter, increase the wire diameter, take some coils out, or reduce the degrees of your torsion spring's free position by only taking a fraction of a coil out so you obtain more force through more travel. For less force, you must increase the outer diameter, decrease the wire diameter, add coils, or increase the degrees of your torsion spring's free position by only adding a fraction of a coil so you obtain less force through less travel.

These stock 5/64" (five sixty-fourths of an inch) inner diameter torsion springs are made out of either 302 stainless steel (ASTM A 313) or music wire (ASTM A 228).