Customizing Standard Springs: Secondaries

Secondaries.

Secondaries are the type of customizations we offer that can be applied to enhance, improve or slightly modify a spring after it has been manufactured. There are different types of secondaries. Some are completed in-house by us while others are additional services completed by third parties that we have established a business relationship with. The standard secondaries process for all springs is heat treating as this relieves the spring of stress and allows it to be able to have memory. However, there are other non-standard secondary processes that are only completed per request and when necessary (usually at an additional cost).

In-House Secondaries

Only a few secondaries are completed in-house. This means that they are completed by our team, using our equipment. Some of the in-house secondaries we complete are: the mandatory heat treating, standard grinding, hooks, bends and certain cuts. Grinding is another standard measure that is widely requested for compression springs. When a spring is grounded, the ends are slightly trimmed so that the spring can stand over a flat surface, thus gaining more stability on both ends.

Third Party Secondaries

Some of the secondaries such as plating, passivation, and shot peening can be completed by third parties. However, we do offer these options at an additional cost. These are done out of house but we can take care of it for you. Some plating options we offer are zinc, gold zinc, nickel, and black oxide. In some very rare cases we also do gold plating. Passivation is a process that gets your spring cleaned thoroughly so that it can be used in food grade applications and medical devices. One service that we do not offer is shot peening and/or powder coating. This secondary is normally requested for heavier, more industrial type springs, and we do not handle many springs like those.

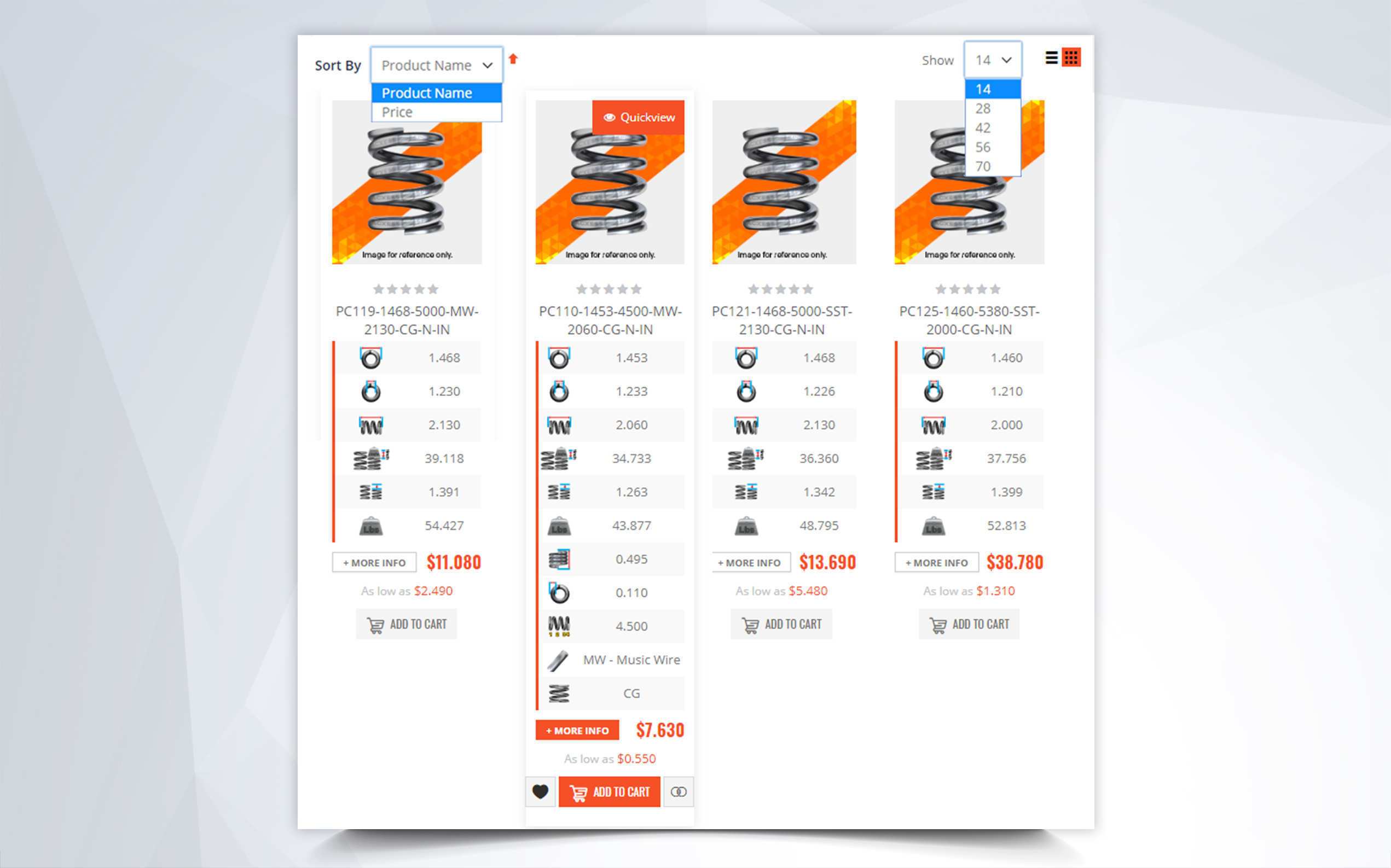

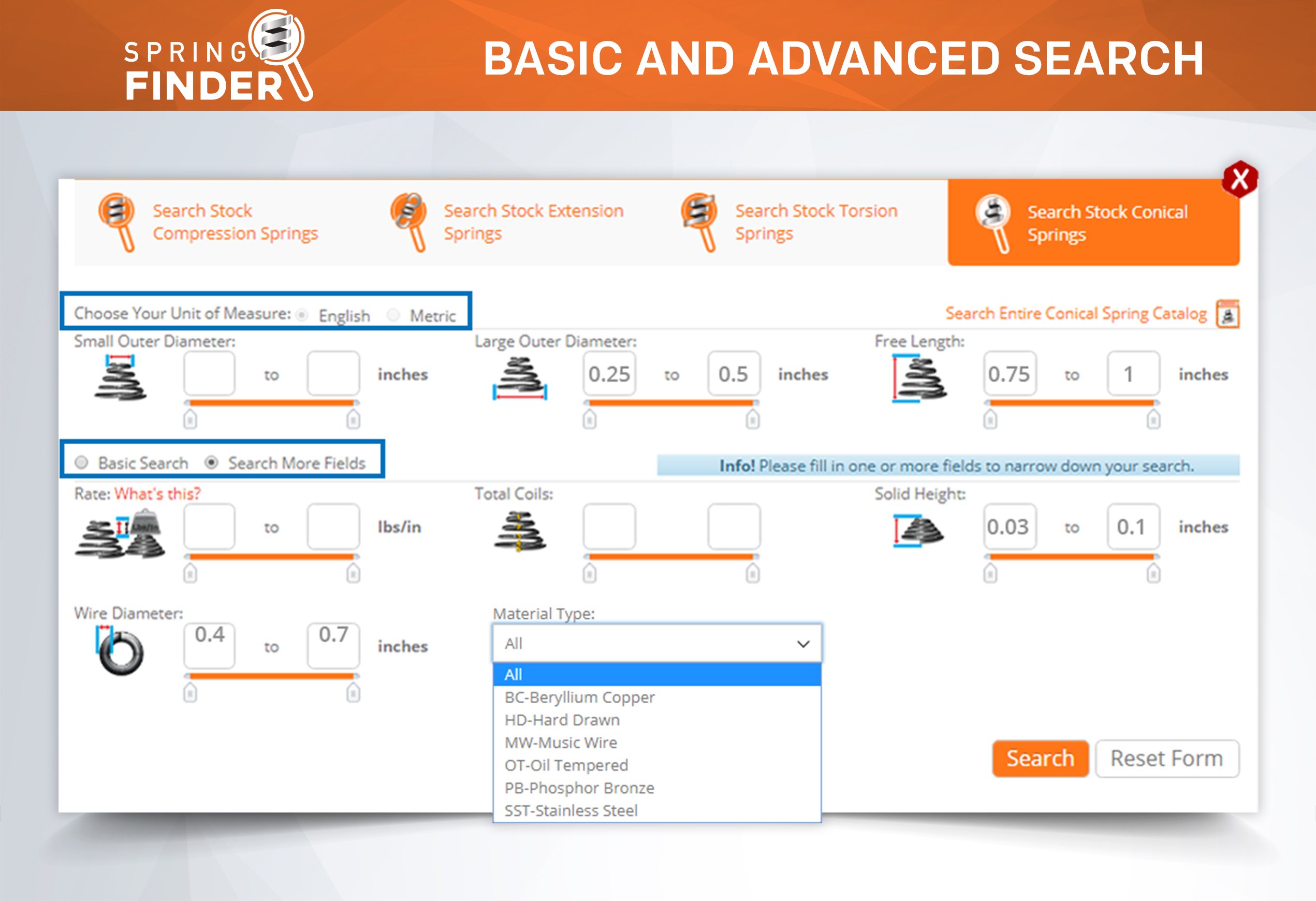

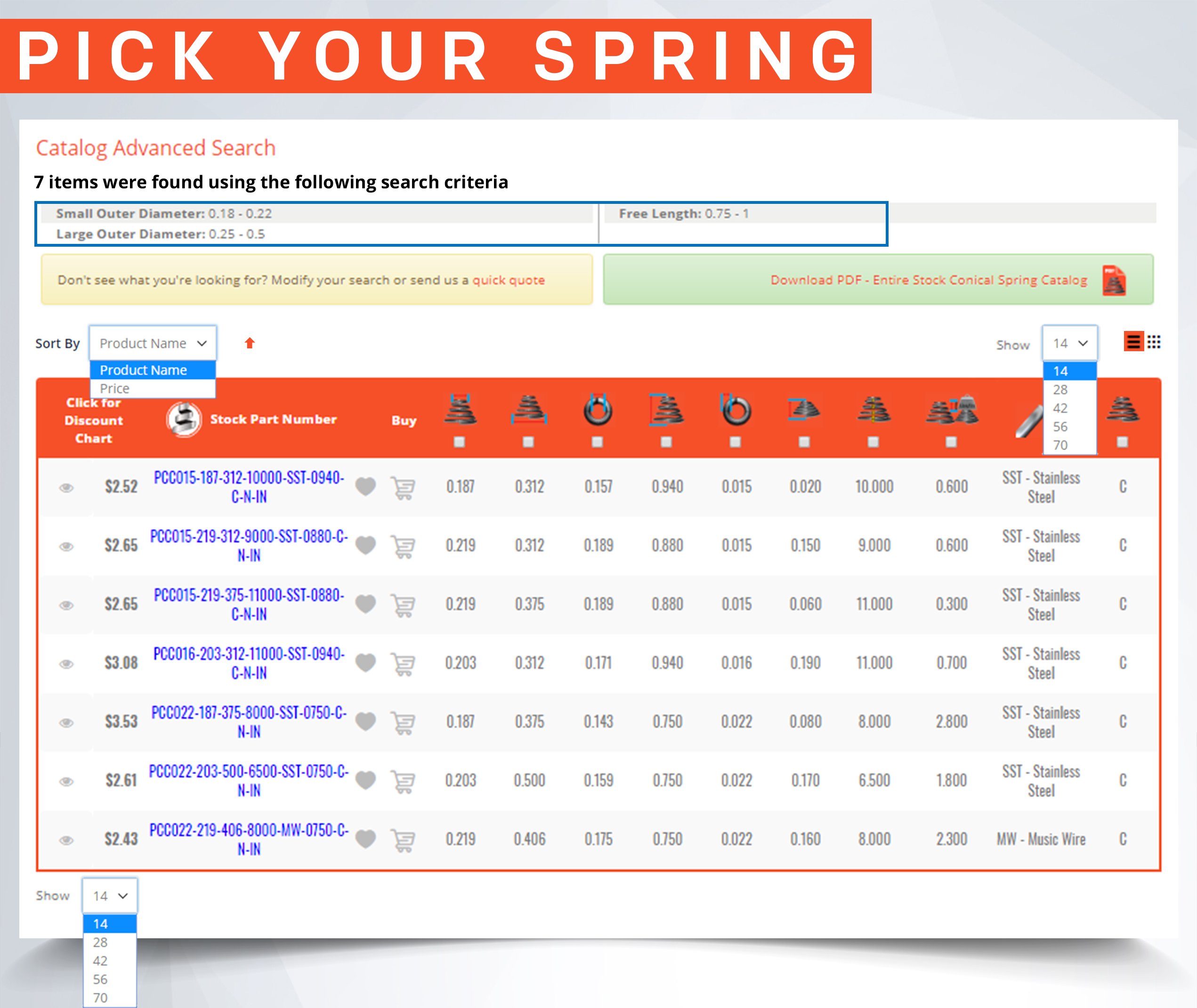

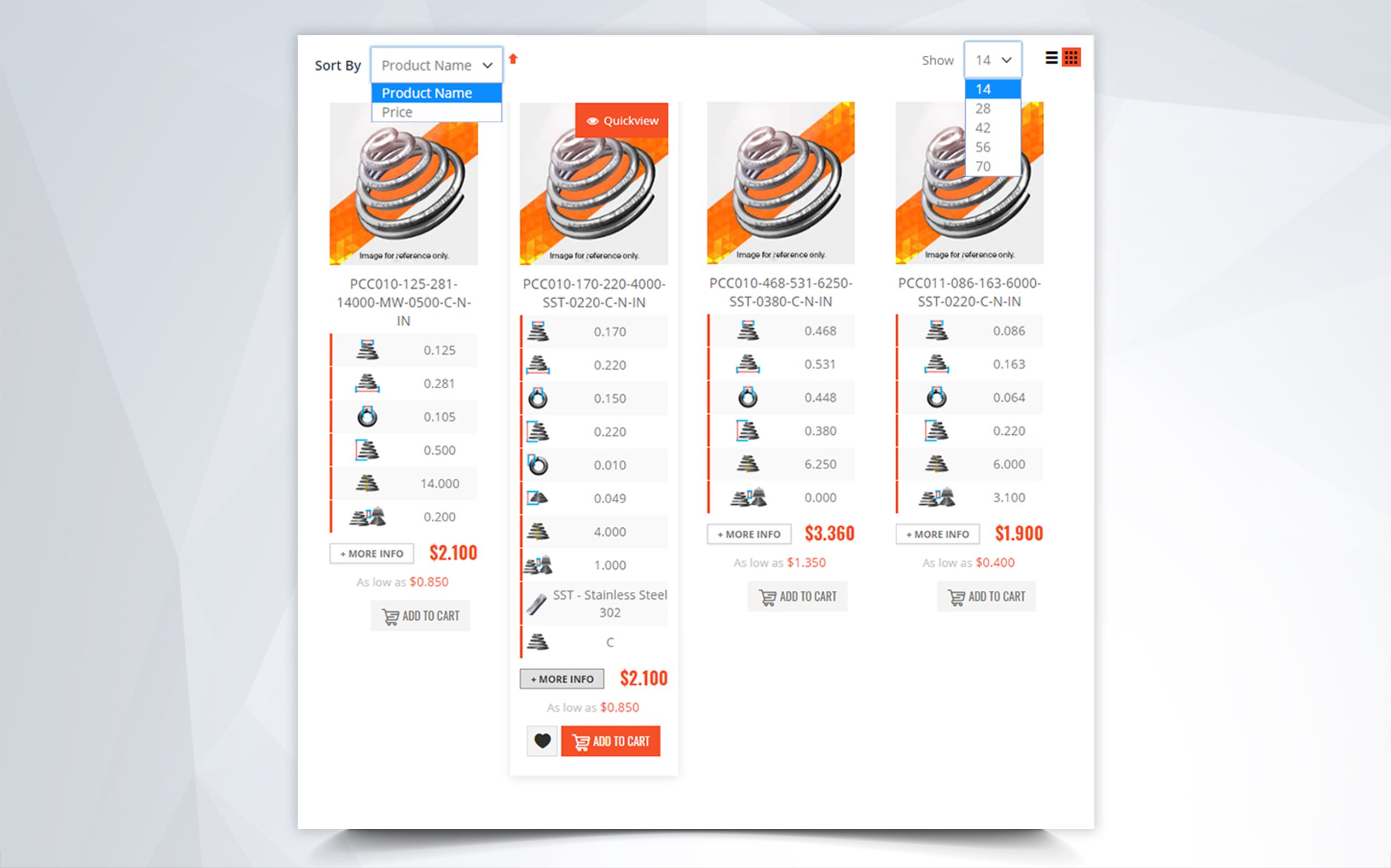

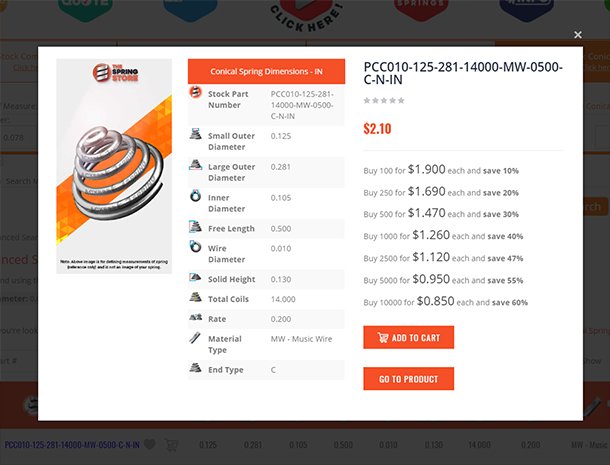

At CompressionSpring.com we offer all kinds of compression springs; from custom compression springs, to stock conical springs. We have an incredible variety and assortment to meet your needs. Since we know every application and project is different, we always like to give our customers more options. That is why, we also offer customizations for large selection of stock springs. Contact us today at (951) 276-2777 and get the best prices on the best stock springs.